Description

ACCURL EURO PRO B40175 – Year 2021

CNC Press Brake 175 Ton

operating hours: 5 h

maximum press force: 175 t (1750 kN)

number of axes: 6 (X, R, Z1, Z2, Y1, Y2)

maximum workpiece length: 4000 mm

maximum slider stroke: 200 mm

bending speed: 7 mm/s

approach speed: 180 mm/s

return speed: 120 mm/s

throat depth: 410 mm

working height: 970 mm

distance between side walls: 3300 mm

maximum operating pressure: 280 bar

oil tank capacity: 350 l

main engine power: 11 kW

power supply: 380 V; 50 Hz

weight of machine EURO PRO B 40175: 11000 kg

Equipment of the press brake

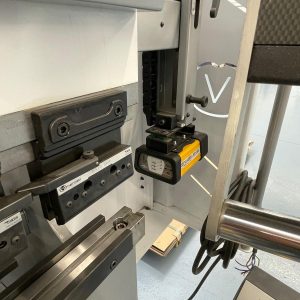

CNC control: DELEM DA-66T

servo-hydraulic system: HOERBIGER

automatic compensation of the deflection arrow

upper and lower tool with “V” shaped die (835 mm)

clamping system of upper and lower tool

light curtains

precision linear encoded sensors in Y1, Y2 axes

foot pedal

electrical control cabinet with cooling system and SIEMENS parts

ACCURL EURO PRO B40175 CNC press brake was manufactured in China in 2021. Equipped with six numerically controlled axes (X, R, Z1, Z2, Y1, Y2), the machine is used to bend workpieces with a maximum length of 4000 mm. The state-of-the-art technology and high quality steel construction ensure excellent machining results at low operating costs.

The press brake is driven by a highly accurate servo-hydraulic system made by HOERBIGER. Thanks to the servo-driven back stop, high press force of 175 tonnes and automatic compensation of the deflection arrow, the workpieces are characterised by high precision and quality as well as an even angle over the entire length of the workpiece. The servo-hydraulic press brake is controlled by a DELEM DA-66T CNC control with colour screen and a function to model the bending trajectory and program the machining parameters.

The offered CNC press also features extensive additional equipment, consisting, of, among others, safety-improving light curtains and an upper and lower tool with a “V” shaped die. The press was in operation for just 5 hours. The total weight of the machine is 11000 kg.