Description

Akyapak ADM 1200 Drilling Line – Year 2010

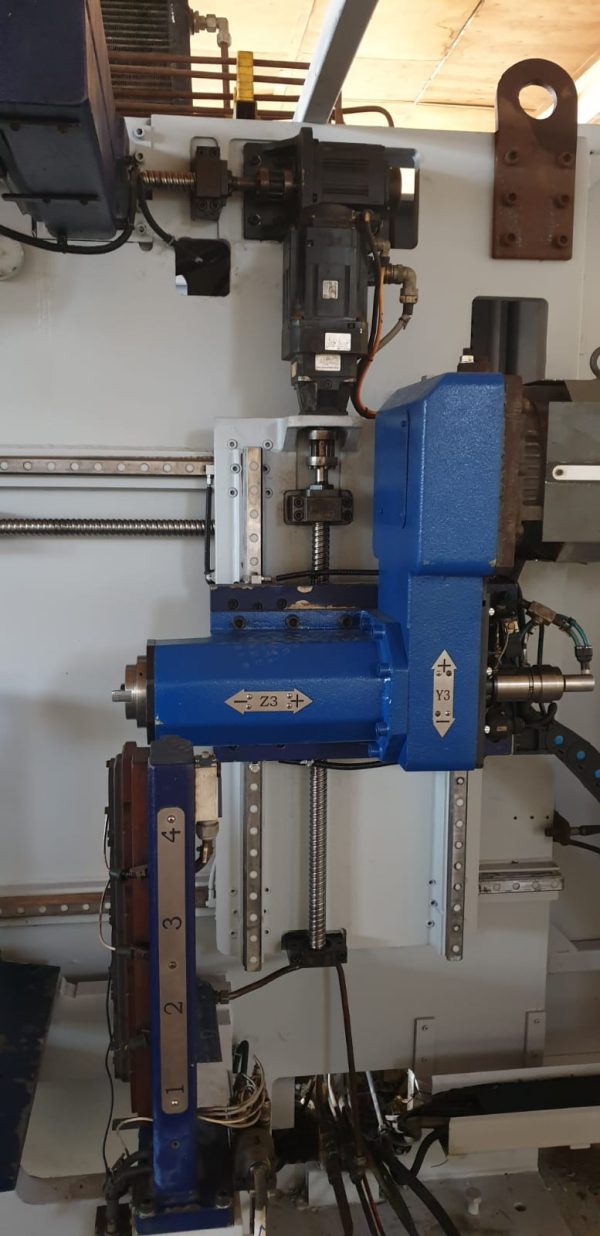

CNC Beam Drilling Line

| Drilling Ø | 40 mm |

| Type | CNC |

| CNC | Mitsubishi |

Akyapak 3 ADM 1200 CNC Drilling Line

Akyapak Angle Saw

Mitsubishi Cnc Control

Machine has been used only 2 years. Since 2012, it is dismantled.

Manufacturer Catalogue Information about Akyapak ADM 1200 Drilling Line :

3 ADM 10 Axis Three Spindle CNC Drill Line

AKYAPAK, as a leader of its sector, shows its technology in steel construction drilling lines and moves it from Turkey to the World. AKYAPAK, created AKDRILL brand in this sector, manufactures CNC drilling machine series with servo motor driven in the name of ADM for steel construction masts.

AKDRILL ADM Drilling Machines provide high quality solutions in manufacturing of steel construction, bridge construction, shipyards and various fields of construction sector. ADM series have the drilling capacity of H, I, and U profiles or angles with 10-40 mm standart diameters or more.

ADM Drilling Lines consist of one, two or three independent spindles. 1 ADM model which has one spindle, has the capacity of drilling the profile from three sides with right angle and by rotating +90/-90 degree. 3ADM model, which has three spindles, has the capacity of drilling the profile from three sides independently, marking and tool changing at the same time. Resetting the equipment to zero and setting to the next drilling position are performed automatically by CNC.

ADM Drilling Lines, manufacuring with first class equipments as Mitsubishi and Siemens, become prominent with quality and reliability with Akyapak’s strong after sales support, as well.

Through 3 independent servo spindle units on 3 ADM model, the profile can be drilled from 3 sides at the same time. There are four tool capacity automatic tool changing system station for each spindle.

Beams can be drilled without driving them throughout the beams’ length of 500 mm. For instance; if the holes’ diameters are 10 mm and the distances between each holes are 40 mm, the spindle is able to drill 12 holes without moving the beam and that means you may save plenty of time within the operation.

And that means very big time saving. Also there is one more advantage of 3ADM system which makes you eligible to make scribing marking on 3 surfaces (Optional). 3-axis marking is also available as an option.

Firstly, material to drill (profile, box profile, angle) is placed on infeed conveyor. The workpiece, being held with handle claw of driving unit, is driven into the drilling machine and the position of the piece is set to zero by laser light.

Drilled workpiece is driven to the angled bandsaw (optional) with handle claw of driving unit. Sawing can be performed in desired lenght and angle (-45/+60”). Sawed rolls of material are driven to the output conveyor.

STANDART FEATURES

- Control Panel: Mitsubishi

- Drilling Unit- Vertical: 1 Vertical

- Drilling Unit- Horizontal: 2 Horizontal

- Drilling diameter: 10-40 mm

- Spindle Speed-Infinitely Infinitivel: 50-3000 d/min.

- Drive Power Per Axis: 22 kW / 140 Nm

- Spindle torque: 280 Nm

- Movement Transmission System: Preloaded ball screws / nut system

- Automatic Tool Changing Unit: For each spindle one ATC with 4 tools

- Infeed Table with CNC Carriage: 12m

- Exit Table with Motorized Rolls: 12m

- Central Lubrication for Linear Guides: Standard

- Tool Cooling System: MQL

- Weight of Linear Meter: 600 kg/m

- Tapping Tool for all three axess (Optional): M10 – M24 (with special set)

- Beam Width max-min with support from down: 1200 / 1500 / 1750-200

- Beam Height max-min: 500 / 600 / 600-80

- Spindle Head Tool Shaftshole: BT 40 (with cooling liguid long hole)

- Workpiece movement: Servomotor + planetery gear box

- Automatic Cross-Section Measuring: Standard

- Miter Band Saw Machine Integration: Optional

- Weight: 13000 kg

- Dimensions of the Machine: 2400 x 7000 x 3200 mm

- D.O.T. Marking: Optional

- Scribing Tool: On each side

- Chip Conveyor: Standard