Description

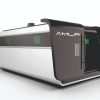

AMLP Raycus RLS200 3015 Fiber Laser Machine

Condition : New

Fiber Laser Machine 2000W

Fiber laser RLS200 3015 2 KW

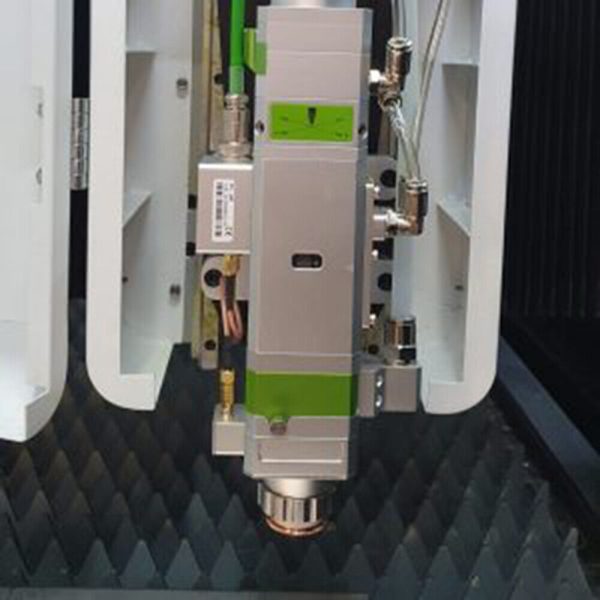

01) Switzerland Raytools laser head Auto-focus laser head

02) Japan Yaskawa Servo Motor

03) X axis: 1 x 0.85KW Japan YASKAWA servo motor Y axis: 2 x 1.8KW YASKAWA servo motors

Z axis: 1 x 0.4KW

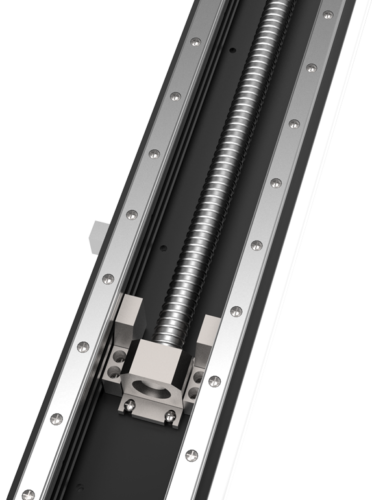

04) Taiwan HIWIN guide rail

05) Taiwan YYC/Taiwan Airtac Rack

06) Japan SMC/Taiwan Airtac Pneumatics

07) France Schneider electr. parts

08) Taiwan TBI ball screw

09) Cyprus operating system

10) Aviation Aluminum Beam

11) S&A water cooling

12) Automatic greasing system

13) Enclosure and work changing table

14) 1500*3000 working table

15) Raycus or IPG fiber laser source 1.5, 2, 3,4,6KW anti-reflection

16) Voltage stabilizer 30kva

17) Raycus Laser Source

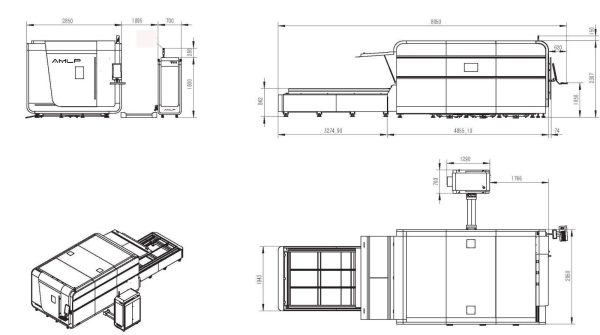

Model RLS2003015

Working area 3000*1500mm

Laser power 2kw

Position accuracy 0.03mm

Repositioning accuracy 0.02mm

Smallest beam width 0.1mm

Machine weight 9000kg

Machine dimensions 8850×2860×2310MM

Max loading capacity 800kg

Max acceleration speed 1.5G

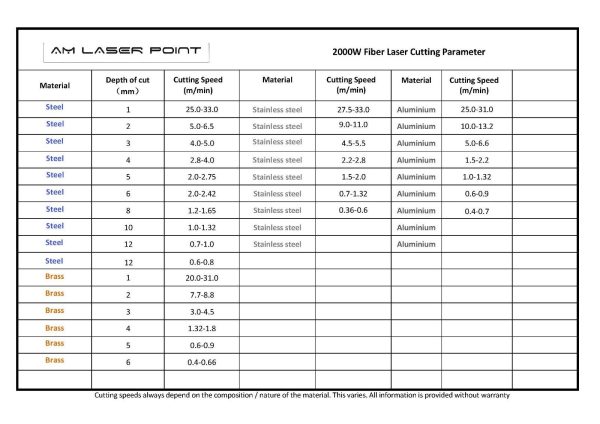

Cutting thicknesses see list

24 hour continuity

Warranty on the machine 1 year

Laser unit warranty Depends on the manufacturer

Cooling water cooling

Voltage 380V

phase triphase

Frequency 50Hz/60/Hz

3rd aluminum generation

1. Engineered for the aerospace industry, this aluminum is formed and pressed at 4,300T. After the hardening process, the aluminum reaches a hardness of 6061 (T6). This aluminum is characterized by its durability, light weight, low density, corrosion resistance = anti-oxidation effect and it increases the moving speed of the laser head.

2. A steel frame weighs about 280kg, ordinary cast aluminum weighs about 180kg, the aerospace aluminum frame weighs only 138kg, which increases the cutting speed.

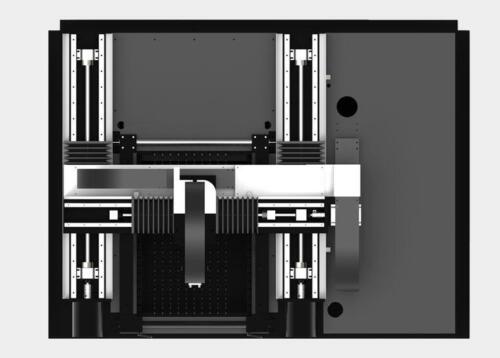

The segmented rectangular tube welding bed

1. Structural advantage: The internal structure of the bed is the same as the honeycomb structure used in aviation. Stiffeners are placed in the tubes and increase the overall strength and tensile strength of the bed. They increase the resistance and stability of the guide rails, thereby preventing the bed from deforming.

2. For Material: The 600℃ heat treatment strengthens and tightens the hold

3. Result: High strength, stability, tensile strength, durability. The material of the built-in supports has a thickness of 10mm.