Description

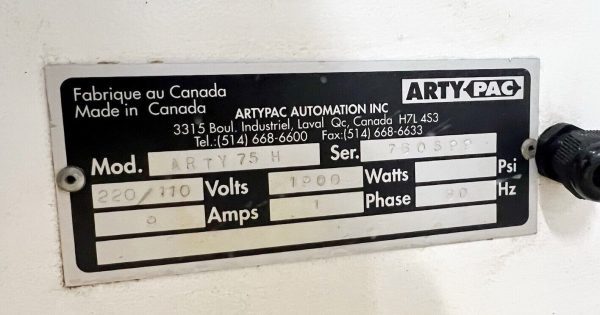

ARTYPAC 75H

Horizontal Flow Wrapper Machine

MANUFACTURER: ARTYPAC

MODEL: ARTY75H

POWER

REQUIREMENTS: 220 VOLTS, 9 AMPS, 1 PHASE

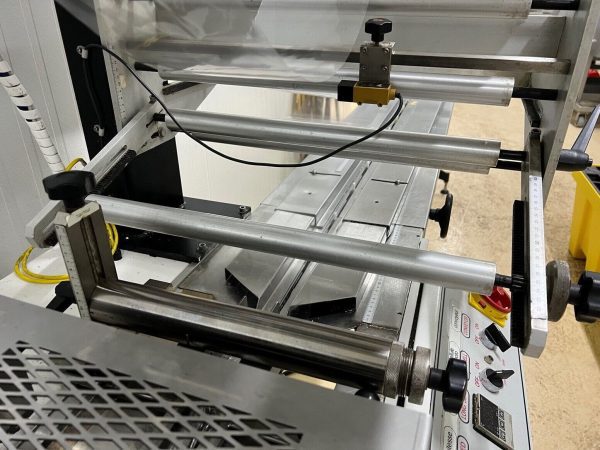

INFEED BELT

DIMENSIONS: 105” LONG

DISTANCE BETWEEN

CLEATS: 5.5”

OUTFEED BELT

DIMENSIONS: 9” WIDE X 48” LONG

DISTANCE FROM

BELT TO GROUND: 36”

PREVIOUS USE: CHOCOLATE

APPLICATION

Manufacturer Catalogue Info :

Fully Automated High Speed Horizontal Flow Wrapper

The ARTY75H is a versatile, low maintenance, horizontal flow wrapper for pillow type applications and offers hi value for the dollar.

The end users are small and medium corporations in the following industries:

Bakeries, bread and pastries

Cookie manufactures

Confectionery manufacturers

Contract packagers

Snack food manufacturers

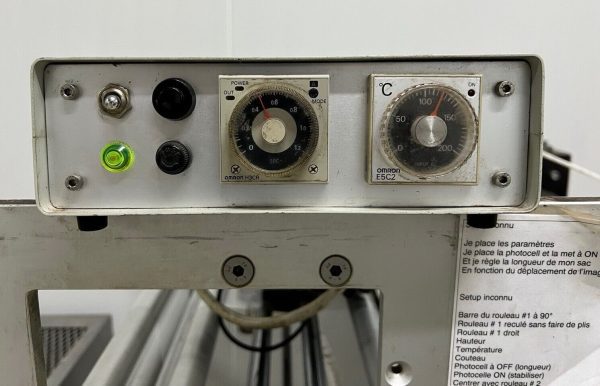

Higher speeds than the industry standards. Single jaw: 125, double jaw: 180, quadruple jaws: 360.

Low energy consumption: A single jaw machine uses only 1.3 KW per hour.

No tools and no special skills are needed for set up. Turn one hand-wheel to adjust the bag length, turn one knob to adjust the bag width, switch off the infeed conveyor and place it in position with the jaws, guide the product with the telescopic side rails.

No change parts needed from one application to another by using an adjustable forming box and telescopic side rails.

Quick change over made possible by using a self-centering reel holder.

Maintenance free drive system using a 3 phases AC motor and variable speed AC drive.

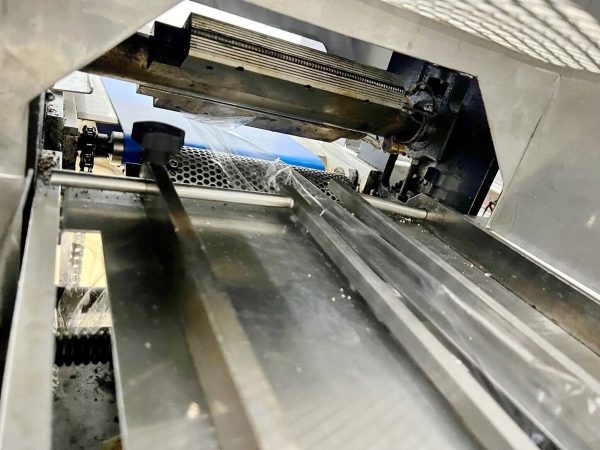

Easy cleaning, all parts in contact with the product are removable without tools and are made from stainless steel #304.

Low maintenance, permanent lubricated gearbox with synthetic oil, mercury rotary switches instead of slip rings and brushes, self-lubricating bearings every where this is possible.

Mobility, the machine can be equipped with four castors and four legs.

All parts and components are sourced in north America.