BLM LC5 FIBER COMBO – Year 2016

Contact us for price

Description

BLM LC5 FIBER COMBO – 2016 Model

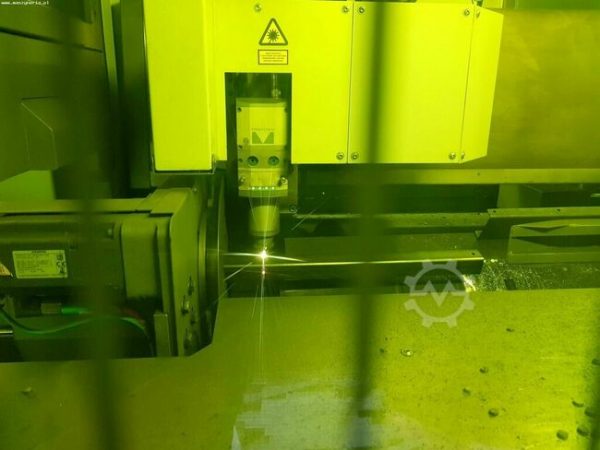

Laser for cutting metal sheets COMBO BLM LC5 FIBER,

pipes and profiles in Fiber 2D technology was built in 2016 in Italy (laser installation: 2017).

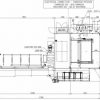

The laser has a transversely replaceable table, equipped with a module for cutting pipes and profiles.

It also has a profile feeder and a receiving table.

It works in an automatic cycle, therefore the operator’s work at the machine consists only in loading the beam of profiles onto the feeder and collecting the finished parts from the unloading table belt.

The machine is designed in such a way that it optimizes the distribution of parts on one profile – after its previous measurement. The LC5 enables you to cut pipes and sheets on one machine.

It is the only solution on the market that guarantees double possibilities on one machine.

The laser enables the execution of machining tasks on materials such as: steel, inox, brass, copper and aluminum.

It cuts small and large sizes of materials with the highest quality and efficiency.

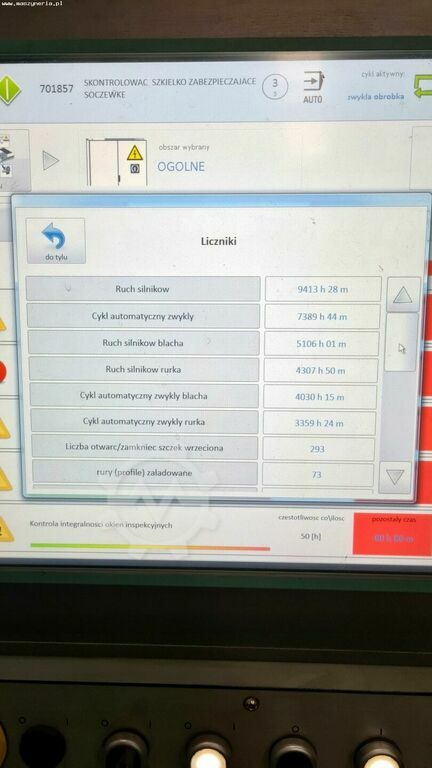

Laser technical parameters:

man-hours: 9500 h

laser source: IPG 4.0 kW, fiber optic

Precitec Procutter head, with automatic zoom

automatic nozzle replacement

sheet format: 3000 x 1500 mm

maximum cutting thickness, black steel: up to 6 mm (Nitrogen), 20 mm (Oxygen)

maximum cutting thickness, stainless steel: up to 6 mm

maximum cutting thickness, aluminum: up to 15 mm

maximum cutting thickness, copper, bronze: up to 6 mm

processing of closed pipes and profiles: up to fi 120 mm

automatic loading of profiles: from 6.5 m

maximum length of a detail, unloading length: 4500 mm

in-line or crosswise pallet change

seam detection

Components of the machine BLM LC5:

sheet metal module

pipe module

IPG resonator

refrigerator

extraction

automatic lime dispenser for cutting aluminum