Description

BURRI BZ 300 – Year 2020

EQUIPPED WITH – CNC Gear Grinding Machine

| Max Gear Dia. | 300 mm |

| Max Diametral Pitch | 3.62 |

| Control | CNC (B&R (Part of the ABB Group)) |

Direct drive spindles.

Acoustic touch.

Fully servo controlled dresser setup.

Conversational based programming.

Remote Diagnostics.

Power clamping.

Servo driven tailstock.

Optional Gantry loader and magazine configuration.

Module 0.5-7.0

Work-piece Length 650mm

Helix angle +/- 45 degrees

Max work-piece weight 60 kg.

Max work-piece speed 3000 RPM

Grinding Pass 400mm

Cutting speed (max) 80 m/sec.

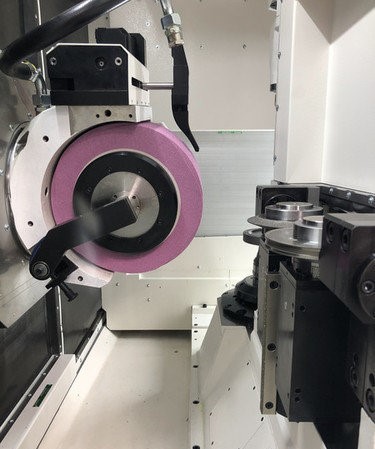

Grinding wheel Diameter 300mm (275mm)

Grinding wheel width 200mm (104-200mm)

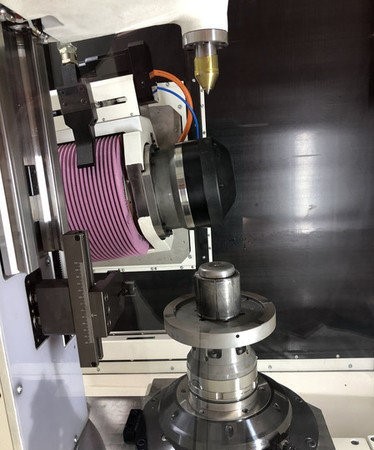

Dressing Disc 120-140 mmWith the newly designed compact grinding spindle with built-in bearings, grinding wheels up to a width of 200 mm can be used without counter bearings. The integrated balancing and acoustic touch system enables a fully automatic setup cycle with the doors closed.The grinding wheels are mounted directly on the spindle without flange. Thus, the grinding wheel can be changed quickly without auxiliary tools and very ergonomically. Due to the large wheel width of up to 200mm, segmented grinding worms with roughing, finishing and polishing zones can be used very economically.

The work-piece spindle with water-cooled direct drive is tuned for the high speed synchronization developed by Burri and prepared for the Burri quick-lock base chuck. After consultation, clamping equipment from other manufacturers can also be used. The machine bed and the main slide are made of mineral casting, which has a high rigidity and damping as well as a good thermal stability.