Description

| Metal length | 3000 mm |

| Power | 4400 W |

| Metal width | 1500 mm |

| Type | CO₂ |

| Option to cut tubes | no |

| Max thickness | 25 mm |

| CNC | yes |

| CNC type | Bystronic ByVision |

| Travel X | 3048 mm |

| Travel Y | 1524 mm |

| Travel Z | 170 mm |

| Max weight of the workpiece | 890 kg |

| Bystronic Bystar 3015 | |

| Length x width x height | 12900.0 × 6100.0 × 2070.0 |

| Weight | 13600 kg |

– laser power: 4.4 kW (4400 W)

– laser type: CO2

– wavelength: 10.6 μm

– dimensions of the work table (length x width): 3000 x 1500 mm

– feeds in the X/Y/Z axes: 3048/1524/170 mm

– maximum cutting thickness (black steel): 25 mm

– maximum cutting thickness (stainless steel): 20 mm

– maximum cutting thickness (aluminum): 12 mm

– maximum workpiece weight: 890 kg

– maximum speed of parallel positioning of the X / Y axis: 80 m / min

– maximum speed of simultaneous positioning of the X / Y axis: 113 m / min

– positioning deviation: ±0.1 mm

– positioning spread: ±0.05 mm

– total power requirement: 52 kW

– fan filter power: 5.5 kW

– dimensions (length x width x height): 12900 x 6100 x 2070 mm

– weight of the dedusting unit: 1100 kg

– mass of the laser source: 1760 kg

– total weight of the BYSTAR 3015 machine: 13600 kg

Equipment of the BYSTRONIC BYSTAR 3015 laser cutter

– CNC controller: BYSTRONIC ByVision

– laser source: BYSTRONIC ByLaser 4400

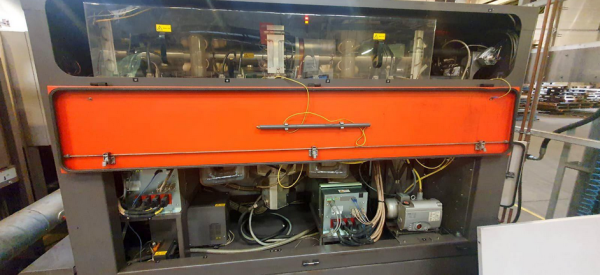

– dust extraction unit: DONALDSON DFPro 6 SPRK

– refrigeration unit: EF COOLING WKL 430

– X,Y,Z axes servo motors

– automatic pallet exchange system

BYSTRONIC BYSTAR 3015 4.4 kW laser cutter was built in 2012 in Switzerland. The machine is equipped with a powerful BYSTRONIC ByLaser 4400 laser source emitting a beam with a power of 4.4 kW and a wavelength of 10.6 μm, it is used for precise shape cutting of details made of black steel, stainless steel and aluminum.

The laser cutter has a solid steel work table, 3000 mm long and 1500 mm wide, which ensures high processing stability when cutting details with a maximum thickness of 25 mm (black steel), 20 mm (stainless steel) or 12 mm (aluminum). The operating modes of the machine are programmed in the control panel placed on the arm with the BYSTRONIC ByVision CNC controller installed.

The laser was serviced on an ongoing basis, during the use of the laser cutter, individual components were replaced with new ones:

– Z-axis motor,

– Z axis servo motor,

– Y-axis servomotor,

– U1 module,

– HU UNIT module,

– SUPPLY UNIT module.

The laser cutter is offered with rich equipment consisting of: DONALDSON DFPro 6 SPRK filter fan, EF COOLING WKL 430 cooler, X, Y, Z axis servomotors and an automatic pallet exchange system. The total weight of the laser punching machine is 13,600 kg.