Chevalier SMART H818 II – Year 2004

Contact us for price

Description

Chevalier SMART H818 II – Year 2004

CNC SURFACE GRINDER PC BASED 2-AXIS

SPECIFICATIONS:

Table Size ………………….. 8″ x 18″

Grinding Capacity ……………. 8″ x 18″

Table Workload Capacity

– w/o Magnetic Chuck …………. 385 Lbs.

Table Workload Capacity

– with Magnetic Chuck ………….. 462 Lbs.

Grinding Wheel Size ……… 8″Dia. x 1/2″W x 1-1/4″B

Magnetic Chuck Size ………….. 8″ x 18″

Table Surface to Spindle

Center Distance …………….. 16″

Table Longitudinal Movement

– Manual Traverse ……………. 19.60″

Table Longitudinal Movement

– Servo Drive Traverse ……….. 19.60″

Table Longitudinal Movement Speed

– Infinitely Variable ………… 0.065′ – 82′ FPM

Table Cross Movement

– Rapid Travers Rate …………. 0 – 10 FPM

Table Cross Movement

– Least Increment Input ………. 0.0001″

Table Cross Movement

– Manual Traverse ……………. 8-3/4″

Wheel Head Elevation Movement

– Rapid Traverse Rate ………… 0 – 10 FPM

Wheel Head Elevation Movement

– Lease Increment Input ………. 0.0001″

Positioning Accuracy …………. 0.0001″

Repeatability Accuracy………….0.0001″

Spindle Speed (AC Drive)

-Infinitely Variable to ………. 8,000 RPM

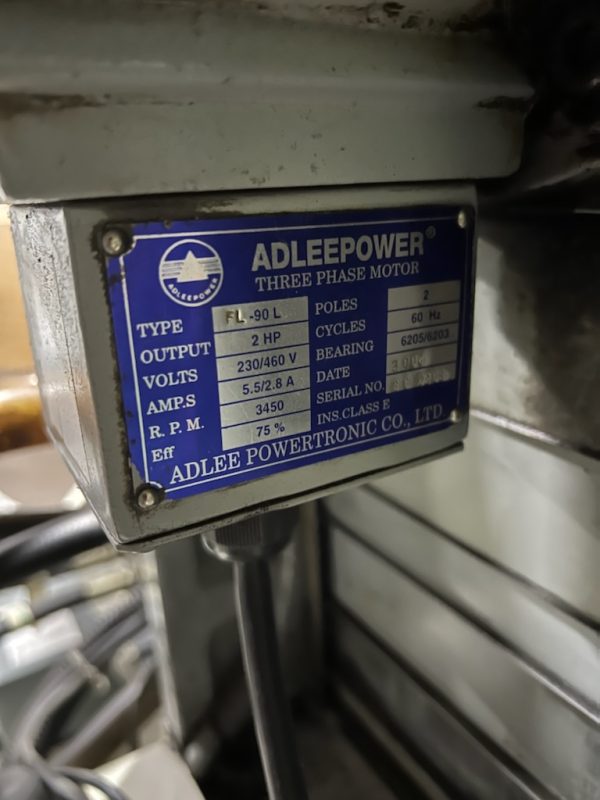

Motor – Spindle ……………… 2 HP

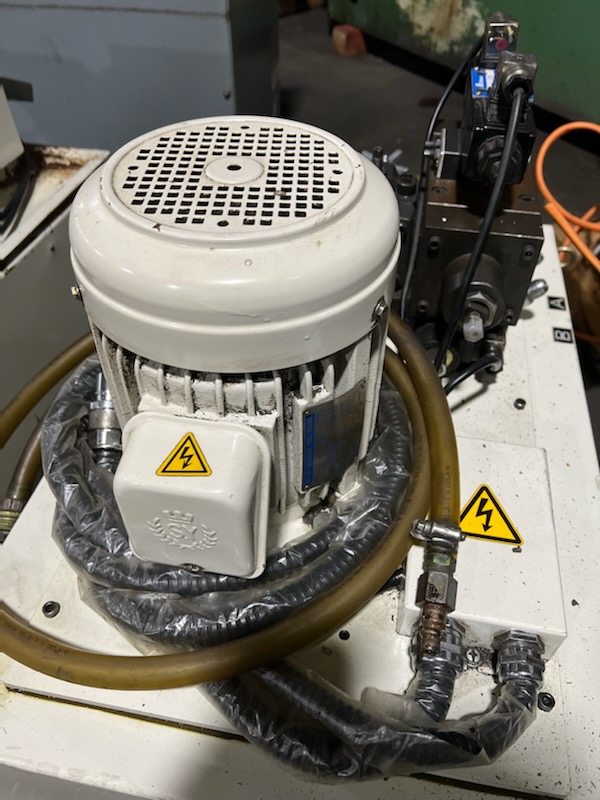

Motor – Logitudinal Hydraulic …. 1 HP

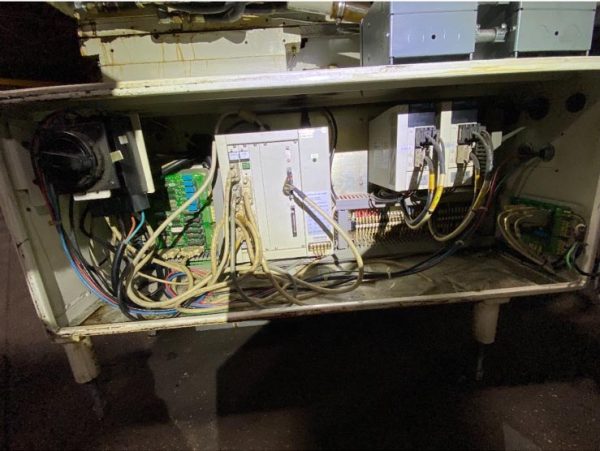

Motor – Crossfeed AC Servo ……. 1.33 HP

Motor – Elevating AC Servo ……. 1.33 HP

Electrics …………………… 220V / 3Ph / 60Hz

Dimensions – Approximate ……… 81″L x 83″W x 83″H

Weight – Approximate …………. 2,665 Lbs.

EQUIPPED WITH:

8″ x 18″ Electro-Magnetic Chuck

Variable Hold Neutrofier Control

Coolant System with Filtration System

3-Face Side Mount Dresser.

Halogen Machine Lamp.

Super-Precision Direct Drive Spindle

Fully Enclosed Factory Enclosure.

Superior Condition & Appearance _ Original Paint

CNC & Conventional Surface Grinder

with Full Factory Enclosure Option

Serial No. S6932001 New – 2004

GENERAL INFORMATION:

The Chevalier SMART H818II –

“Microsoft WinCE Platform, 2-Axis

Conversational CNC. Semi-automatic or manual

operations use hydraulic drive for

longitudinal table movement.

Conversational factory-programmed canned

cycles, simple conversational graphics

with preview function and

surface/plunge/crisscross/profile grinding modes.

Programming, a graphic program

input function avaialable for grinding

and dressing with auto compensation,

It is easy to operate and can combine the

grinding cycle, wheel dressing and auto

compensation without using a CNC program.

The wheel dressing can be executed

during the grinding cycle. It can simulate

the grinding path and dressing cycles by

turning the MPG handwheel.

It can Grind multi-slots with different

pitch and depth.

Conversational and G-code programs can be saved on

a hard drive or floppy disk. It is FANUC CNC Program

compatible and has a patented longitudinal stroke

adjustment from the screen.

• High precision spindle is supported by

four pieces of class 7 (P4) super precision

angular contact ball bearings and directly

coupled with low vibration class V3 spindle

motor, suitable for heavy duty grinding

• Counterweight balance device on spindle

housing to reduce load burden • Headstock

elevation accuracy is adjusted by gibs and

designed with counterweight balance device

to ensure the micro downfeed accuracy

• Base and saddle, specially designed

one-piece T-shaped base casting offers

superior rigidity

* Precision C3 grade ball screws on cross feed

and down feed axes directly mounted via

coupling to the Mitsubishi® AC servo motors

• Hand scraped, Turcite B coated crossfeed

guideways between base and saddle have double

“V” design, provides support for full table

travel and prevents table overhangs

• Hand scraped, Turcite B coated longitudinal

ways between table and saddle are double

“V” design, ideal for delicate side grinding

operations

• Hydraulic creep-feed function. Table longitudinal

movement speed can be adjusted easily by

turning two knobs

• Quick lock/unlock mechanism. Hydraulic cylinder

can be disengaged very quickly for quick fixture

alignment

• Recirculating forced lubrication system

on all guideways