Description

Citizen Cincom A20 VIPL – Year 2006

| Max. Ø | 20 mm |

| Max. length | 165 mm |

| Type | CNC |

| Type of CNC | FANUC 32i |

| Nbr of axes | 7 |

| Number of tools | 21 |

| Spindle speed | 8000 rpm |

| Spindle power | 3.7 kW |

| Citizen Cincom A20 VIPL | |

| Length x width x height | 2120.0 × 1240.0 × 1750.0 |

| Weight | 2300 kg |

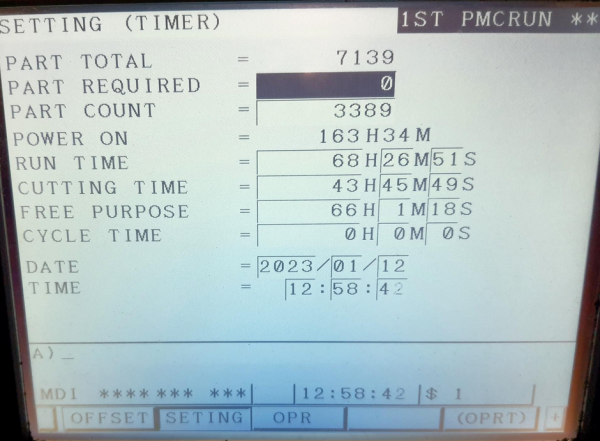

| Worked hours | 69 hours |

Technical data of the CITIZEN CINCOM A20 VIPL CNC lathe

– number of axles: 7

– accelerated feeds in the X1 axis: 18 m/min

– accelerated feeds in the Y1, Z1, X2, Z2 axis: 32 m/min

– maximum turning diameter (main spindle): 20 mm

– maximum turning length: 165 mm

– maximum main spindle speed: 8000 rpm

– maximum power of the main spindle drive: 3.7 kW

– spindle indexing (C axis, main spindle): every 0.001°

– maximum turning diameter (intercepting spindle): 20 mm

– maximum grip length: 80 mm

– maximum speed of the intercepting spindle: 8000 rpm

– maximum power of the intercepting spindle drive: 1.5 kW

– spindle indexing (C axis, intercepting spindle): every 0.001°

– bar diameter range: 2-20 mm

– automatic bar replacement

– total number of tools in the head: 21

– number of driven tools: 4

– number of cutting tools: 5

– number of fixed tools for drilling from the front: 4

– number of fixed tools for drilling from the back: 8

– maximum speed of driven tools: 8000 rpm

– drive power of driven tools: 0.75 kW

– man hours: 69 h

– coolant tank capacity: 150 l

– dimensions (length x width x height): 2120 x 1240 x 1750 mm

– machine weight: 2300 kg

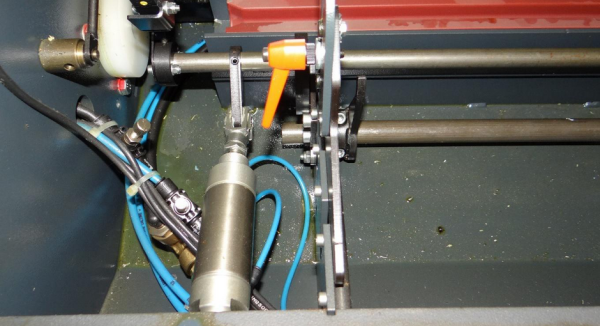

Equipment of the CINCOM A20 automatic lathe

– CNC controller: FANUC 32i

– bar feeder: LNS Express 220

– intercepting spindle

– detail transporter

– workpiece separator (device for receiving finished workpieces from the intercepting spindle)

– workpiece ejection device with a through hole

– 5-position cutting tool support

– 2×4 position support for processing from the back

– 4-position support for front-facing processing

– main spindle mounting sleeve: TF25

– guide sleeve with drive

– air sealing collar

– rotary holder drive

– central lubrication

– lighting of the working space

CITIZEN CINCOM A20 VIPL longitudinal automatic lathe, manufactured in 2006, was designed to provide the user with high speed, precision and versatility. The rigid structure of the bed with high thermal stability guarantees the highest precision and durability by reducing the impact of heat, also during continuous production. The modular structure with a reduced number of parts means that the CINCOM A20 VIPL CNC lathe can be used in various types of production by customers with the highest requirements.

A Swiss-type CITIZEN automatic lathe equipped with an intercepting spindle and 7 numerically controlled axes, processes workpieces with a maximum diameter of 20 mm and a length of 165 mm. The main spindle integrated with the engine creates the so-called electrospindle, guaranteeing the highest precision and reduction of acceleration and deceleration times. The sleeve is synchronized with the main spindle and is driven by a separate AC motor.

The whole thing is controlled by a FANUC 32i CNC controller, which allows for a significant increase in processing speed and reduction of auxiliary times. A standard memory card slot located directly next to the monitor facilitates archiving and transferring programs. There is also an electronic wheel next to the monitor, which allows you to check programs at any speed.

The bar machine is offered with extensive equipment, including: LNS Express 220 bar feeder, device for receiving finished parts from the intercepting spindle and driven tools. During use, the longitudinal machine with a bar feeder worked for only 69 hours. The total weight of the machine is 2300 kg.