CMS Ares 4818 – Year 2006

Contact us for price

Description

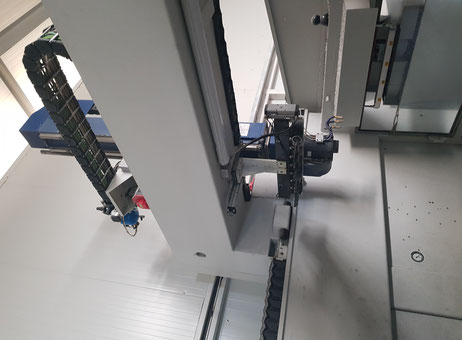

CMS Ares 4818 – Year 2006

| Axis X | 4800 mm |

|---|---|

| Axis Y | 1800 mm |

| Axis Z | 1200 mm |

| Type | Vertical |

| Type | Continuous |

| CNC | fanuc |

| Type of axis | Twist head |

| Table length | 4840 mm |

| Table width | 1360 mm |

| Number of tool pockets | 12 |

| Spindle taper | HSK63 F |

| Max. spindle speed | 24000 rpm |

| Spindle motor power | 12 kW |

| Number of pallets | 1 |

CMS Ares 4818 – 2006 Model

Center of Machining CMS with numerical control of 5 interpolated axes n / type “ARES 4818 12KW” of characteristics:

Open structure of double support mobile bridge. Fixed Table

Shaft travel: X = 4,800 mm, Y = 1,800 mm (Gantry), Z = 1,200 mm. B = ± 120º, C = ± 270º

Speeds in rapid: X = 80,000 Y = 80,000 Z = 70,000 mm / min., B = 9,000 and C = 9,000 º / min.

N.1 Aluminum working plane (4,840 x 1,360 mm.) With threaded holes.

N.1 TUCU type head, CMS mandrel with automatic transmission and 12 kW S1 motor, cooled to liquid. Rot. maximum 24,000. Connection HK 63 F

Pressurized tool holder located under the crossbar of 8 pos. (steel man.)

Second side store of tools of n.4 positions.

N.1 Frequency converter suitable for the electric motor, adjustable speed from 1,000 to 24,000 r.p.m.

FANUC 18i Full Digital numerical control. FANUC portable keypad with steering wheel and keyboard functions.

Panel of control and video TFT of 17 “color + PC Office on electrical cabinet.

Tele-assistance option

Installation of double vacuum with N.10 + 10 indoor connectors

Oil-mist nebulization system.

Electric cabinet with air conditioner, located on the right, is part of the structure

Supply voltage: 400 V. – 50 Hz.

Centralized compressed air installation at 6 Kg / cm2. Direct individual intake of the client

Installation of centralized lubrication with grease reservoir

Opening and closing of pneumatically operated doors

Fixed, removable central stool

Complete machine of safety devices in compliance with standards C.E.

Standard Equipment

Machine in operation