Description

Commersald Implanti PTA200 ROT Welding Cladding System – Year 2013

Machine Specs:

What is Welding Cladding System?

A welding cladding system, also known as a weld overlay system or cladding machine, is a specialized equipment used in the field of welding to apply a protective or functional layer of material onto the surface of a base metal. This process is known as cladding or weld overlay.

The purpose of welding cladding is to enhance the properties of the base metal, such as corrosion resistance, wear resistance, heat resistance, or to provide other desired characteristics. It involves depositing a layer of material onto the base metal surface through a welding process.

Here are the key components and features typically found in a welding cladding system:

- Cladding Torch: The cladding torch is the main component of the system responsible for depositing the cladding material onto the base metal. It is usually a specially designed welding torch that can accommodate the cladding consumables and deliver the required heat and shielding gas.

- Cladding Consumables: Cladding systems use consumable materials in the form of wires, strips, or powders that are fed into the cladding torch. These consumables consist of the cladding material, which can be a different alloy or composition compared to the base metal. Examples of cladding materials include stainless steel, nickel-based alloys, cobalt alloys, and various other specialty alloys.

- Power Source: The welding cladding system requires a power source to provide the necessary electric current for the welding process. This can be in the form of a welding generator or a power supply unit specifically designed for cladding applications.

- Control System: The system may have a control unit that allows the operator to set and adjust various welding parameters, such as voltage, current, wire feed speed, and travel speed. This ensures proper control and consistency during the cladding process.

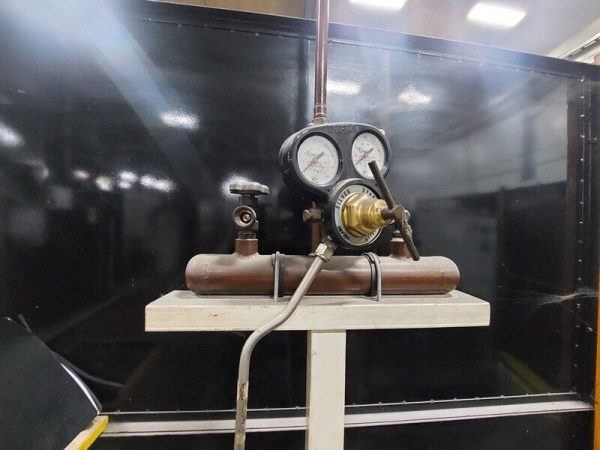

- Gas Shielding System: Cladding often requires the use of shielding gas to protect the molten weld pool and the cladding material from atmospheric contamination. The system may include a gas supply and a gas nozzle to deliver the shielding gas to the welding area.

The operation of a welding cladding system typically involves the following steps:

- Surface Preparation: The base metal surface is prepared by cleaning, degreasing, and sometimes preheating to ensure proper adhesion of the cladding material.

- Cladding Material Selection: The appropriate cladding material is chosen based on the desired properties and requirements of the final cladded surface.

- Cladding Torch Setup: The cladding torch is set up with the selected cladding consumable, and the welding parameters are adjusted based on the specific application.

- Welding Process: The cladding torch is moved along the surface of the base metal, depositing the cladding material through the welding process. The operator controls the torch movement, welding parameters, and ensures proper shielding gas coverage.

- Inspection and Finishing: Once the cladding process is complete, the cladded surface is inspected for defects, thickness, and overall quality. Additional finishing operations, such as grinding or machining, may be performed to achieve the desired surface finish.

Welding cladding systems are widely used in industries such as oil and gas, petrochemical, power generation, and aerospace, where the protection and enhancement of base metal surfaces are critical. The cladding process allows for the application of specialized materials onto specific areas, providing cost-effective solutions for extending the service life and performance of components exposed to harsh environments or demanding operating conditions.