Description

CORIMA VIAL FILLING LINE – Year 2015

CORIMA Vial Filling Line,

24,000 Vials/Hour,

Format: 2, 3, 4, 5 and 6ml Vials,

LINEA WR 16 Vial Washer,

s/n C01144003/C1140004,

STERY-LC Vial Filling Machine,

s/n C2140013, STER

Vial Complete Line

Complete line for vials composed of: Depalletizer, Depacker, Blower, Filler/Capper, Labeller, Cartoner with Robocombi, Carton labeller, Case Packer and Palletizer with Gigacombi

What is Vial Filling Line?

A vial filling line is a manufacturing system used in the pharmaceutical and biotechnology industries to fill vials with liquid or solid substances. It is a highly automated and controlled process designed to ensure accurate and efficient filling of vials with various types of medications, vaccines, or other liquid or powdered products.

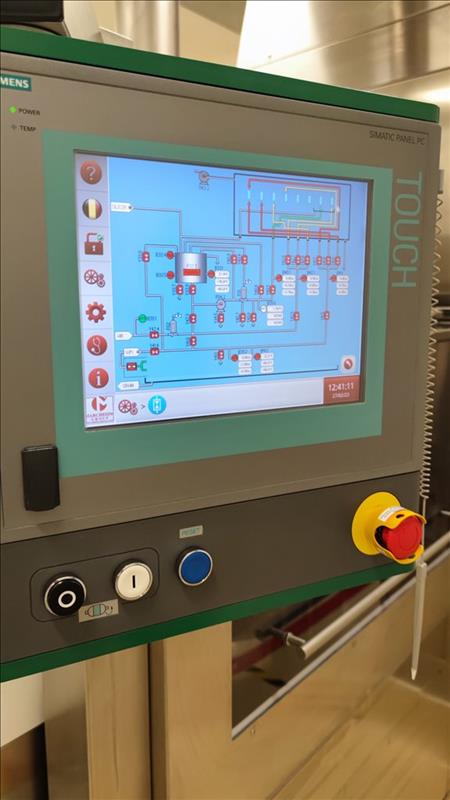

The vial filling line typically consists of several interconnected machines and equipment that work together to carry out the entire filling process. Here are the key components commonly found in a vial filling line:

Vial washing machine: This machine cleans and sterilizes the vials before filling to remove any contaminants or particles.

Vial sterilization tunnel: It is used to pass the washed vials through a controlled environment to ensure their sterility.

Filling machine: The filling machine is responsible for accurately filling the vials with the desired volume of liquid or powder. It can be designed for various filling techniques, such as gravity filling, pressure filling, or vacuum filling, depending on the product requirements.

Capping machine: After filling, the vials need to be sealed with caps or stoppers. The capping machine automatically places and secures the caps on the vials.

Inspection system: This system includes various quality control mechanisms to inspect the filled vials for any defects, such as improper filling levels, visible particles, or damaged caps.

Labeling machine: Once the vials are filled and sealed, a labeling machine applies the necessary labels with product information, dosage instructions, and barcodes.

Packaging and cartoning: The vials are then packaged into boxes or cartons for transportation and storage. Automatic packaging and cartoning machines can handle this process efficiently.

Track-and-trace system: This system helps track and trace each vial throughout the manufacturing and distribution process, ensuring product safety and compliance with regulatory requirements.

Overall, a vial filling line is designed to meet stringent quality standards, maintain product integrity, and optimize production efficiency in pharmaceutical and biotech manufacturing facilities.