Description

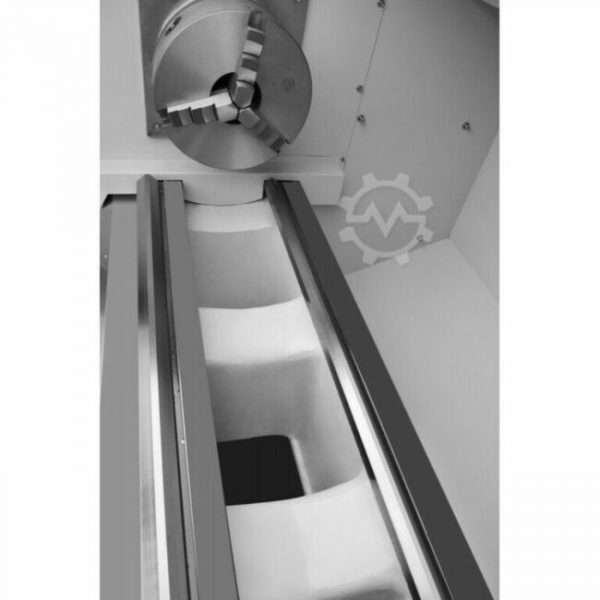

CORMAK CNC CKT 400×1000 – Year 2020

An efficient lathe with a flat bed and a broad scope of big and small scale machining possibilities. This machine can lathe external, internal, spherical surfaces and threads. Using constant cycles for transverse turning, normal turning, tapering, threading, plunge cutting and contouring drastically simplifies the setup and decreases the time of machining.

Technical data:

Swing over bed: Φ 400 [mm]

Swing over cross slide: Φ 210 [mm]

Maximum turning length: 1000 [mm]

Spindle speed range: 0-2000 [rpm]

Spindle bore: Φ51 [mm] (optional Φ68 [mm])

Spindle bore taper: MT6

Number of tools in the holder: 8 (optional 10)

Maximum tool holder size: 20×20 [mm] (optional 25×25 mm)

X/Z axes smallest setting unit: 0.001 [mm] ; 0.001 [mm]

X-axis feed speed: 8 [m/min]

Z-axis feed speed: 10 [m/min]

Tailstock spindle taper: MT4

Maximum tailstock spindle feed: 120 [mm]

Main motor power: 5.5 kW

(X) feed engine: 6 Nm

(Z) feed engine: 6 Nm

Dimensions: 2640×1500×1766 [mm]

Weight: 1800 [kg]

Available equipment:

SINUMERIK 808D control system in Polish and English

SIEMENS servomotors

hydraulic chuck

8-position tool holder

soft jaw kit

hydraulic tailstock

cooling system

automatic gear and guide lubrication system

24V halogen lighting

Polish and English manuals

EC declaration

Optional equipment:

10-position tool holder

EC declaration

follow rest

steady rest

additional set of soft jaws

set of hard jaws

tool holders

CAD/CAM software