Description

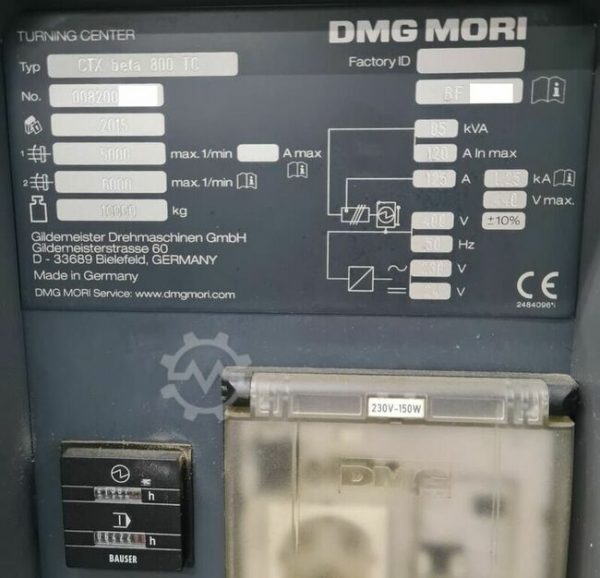

DMG MORI CTX Beta 800TC – Year 2015

DMG MORI – Universal Turn-Mill Machine

CTX Beta 800TC

Year 2015

CELOS with Seimens 840D SL – 21.5” ERGCOline control

Max. turning diameter 500 mm

Max. turning length 800 mm

Integrated spindle motor with C-Axis (0.0001°) 5,000 rpm

Sub-Spindle motor with C-Axis (0.0001°) 6,000 rpm

Max. bar work capacity dia.102 mm

Max. spindle speed turn-mill spindle 20,000 rpm

Max. number of tool stations 80 Pockets – HSK-A63

Y axis +/- 100mm

B axis +/-110° interpolating

Absolute, Direct Measuring system X,Y & Z axis

Cooling system for motor spindle

Excentric turning & milling operation

Tool system milling via gear hobbing

5 axis simultaneous machining

Technology cycle for the application of an alternating speed for vibration

Cycle to create a thread with a free outline as for large & special threads

Counter spindle as integrated spindle motor ISM52

Drive power 20/27KW

Partial hollow clamping

Draw tube ID – dia. 52mm

C axis spindle brake

Basic Slide (Z3) AC servo motor drive with absolute encoder

Coolant thru’ spindle & pneumatic piece ejecting device

Chuck rising device

Tailstock function including pedal switch

Hydraulic hollow clamping attachment dia. 67mm, pull force 68KN

Compact cooling system c/w

Coolant tank – 600L

8 bar/ 20L/min

Programable supply for Turing & Milling function

Level control pump

Chuck rising device for main spindle

Chuck rising device for Sub spindle

Coolant Supply through the main/sub spindle

Chip conveyor

Signal Lamp – 4 colour

DMG Netservice – for internet-base diagnostics service

DMG MORI Messager

Tool breakage monitoring system

Complete machining of shaft components without process interruptions on turning machines with

sub-spindle.

Full accuracy report upon confirmations.