Description

| # Axis | 9 |

| Chuck Size | 406.4 mm |

| Bar Capacity | 104.14 mm |

| Power | 52.2 kW |

| Swing | 629.92 mm |

| Machining Length | 2,049.8 mm |

| Tailstock | Yes |

| Dimensions | Length:299” Width:166” Height:100” |

| Weight | 52,910 lbs |

| Control | CNC (Siemens 840D) |

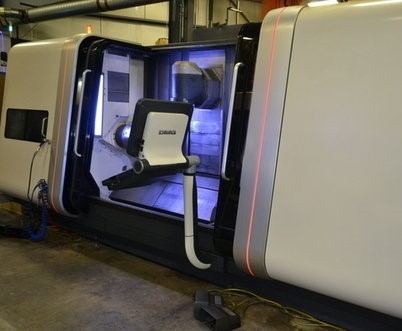

DMG MORI – CTX GAMMA 2000 TC

CNC Mill Turn Lathe – 9 Axis Simultaneous

Control: Siemens 840D Model Year: 2012 Installation Date: 12/2013 Like new condition

machine for half the new price!

Used for simultaneous 5 axis machining of prototype parts.

AXIS

X1=650mm (25.59 inch)

Y1=400mm (+/-200mm, +/-7.87 inch)

Z1=2050mm (80.70 inch)

Z2=1910mm (75.19 inch)

Z3=1910mm (75.19 inch)

B=+/-120 (0.001°)

Size:

Length:299”

Width:166”

Height:100”

Weight: 52,910lbs

TURNING/MILLING SPINDLE

Capto C6 8000 RPM,

43hp (High Torque Option)

TOOL CHANGER

Disk magazine, 36 pocket

MAIN SPINDLE

Swing: 630mm (24.8 inch) Power: 70hp/1622lb*ft Speed: 2500RPM Chuck: 16” SMW-Autoblok KNCS 400-128 Draw Tube ID 4.09 inch C-axis 0.001° (simultaneous 5 axis milling) Hydraulic Brake

COUNTER SPINDLE Swing: 630mm (24.8 inch) Power: 61hp/568lb*ft Speed: 4000RPM Chuck: 13” SMW-Autoblok KNCS 400-128 Draw Tube ID 4.09 C-axis 0.001° (simultaneous 5 axis milling) Hydraulic Brake

OPTIONS High pressure coolant system, factory coolant chiller, 600 liters, 0.04um band filtration. Dual CTS, 300psi, 1000psi pumps. Flushing of chucks, steady rest, way covers. Hinge Type Chip Conveyor Automatic Cabin Doors Chiller system, cooling Milling/Turning Spindle, Main and Counter Spindles. Balanced pressure clamping for main and sub spindles.

Very desirable for thin wall components, applies and monitors pressure on both sides of cylinders to counterbalance actuation and pressure.

Steady Rest: SMW-Autoblok SLU 5.1 (3.35-13.78”) Fully programmable axis and clamping. Positioning independent or movement synchronous to the sub spindle.

Sub Spindle as tails stock option with programmable movement and force monitoring.

Accessories Capto C6 tooling assortment 70 pcs (apox)