Description

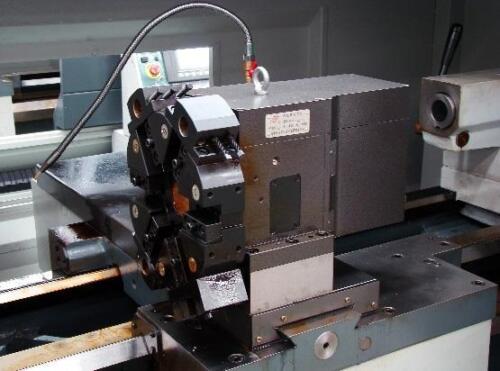

DRC Machinery CK6140 – CNC Flat Bed Lathe

Condition : New

|

Model

|

CK6140*750mm (GSK980TC3 system)

|

|

Processing ability

|

Unit ( mm )

|

|

Max. swing over bed

|

400

|

|

Max. swing over slide

|

240

|

|

Max. Processing length

|

750mm(Optional:500/1000/1500)

|

|

Travel

|

|

|

X/Z axis travel

|

280/750

|

|

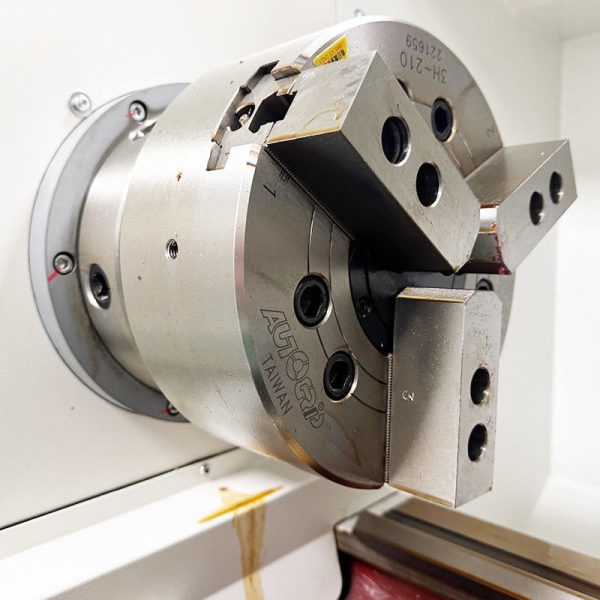

Spindle nose

|

A2-6

|

|

Spindle

|

|

|

Spindle bore diameter

|

82

|

|

Pull tube hole diameter

|

65

|

|

Spindle inner hole taper

|

40°

|

|

Spindle series

|

stepless

|

|

Max. spindle speed

|

150-2000 rpm

|

|

Workpiece clamping mode

|

Manual chuck K8-200

|

|

Main motor power

|

5.5/7.5 kW

|

|

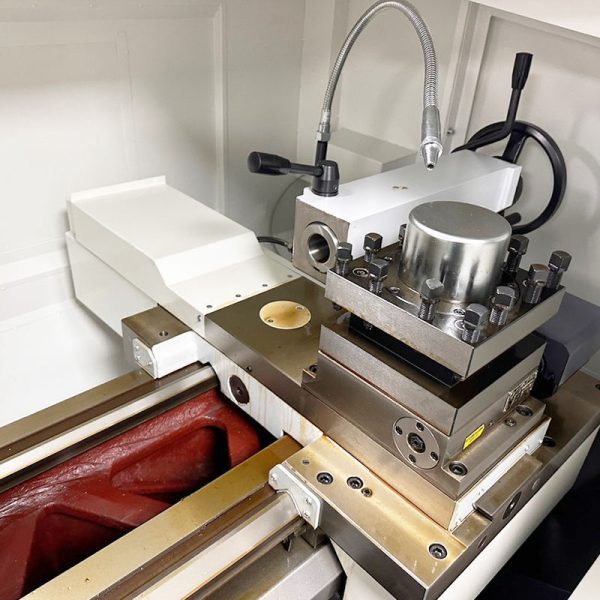

Feed turret

|

|

|

X/Z axis torque

|

5/7.5 N.m

|

|

X/Z axis rapid speed

|

6/8 m/min

|

|

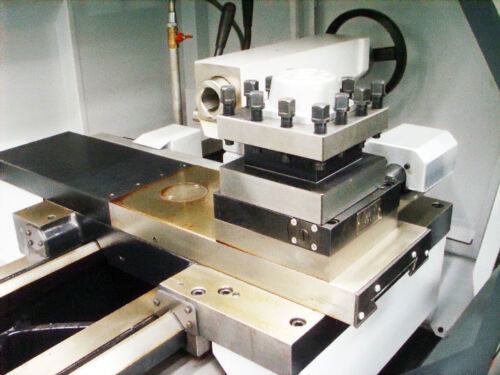

Turret type

|

Electicity

|

|

Tool shank size

|

20×20

|

|

Turret repeatability

|

≤0.004

|

|

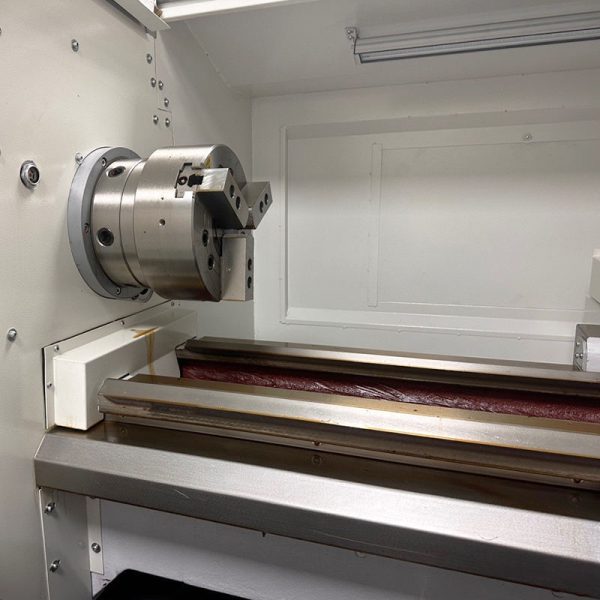

Tailstock

|

|

|

Tailstock diameter

|

60

|

|

Tailstock travel

|

100

|

|

Tailstock center taper

|

Morse 4#

|

|

Others

|

|

|

Machine net weight

|

1800kg

|

|

Machine dimension(L×W×H)

|

2200×1160×1620

|

|

Power supply(power/ electric current)

|

11kW/20A

|

|

Standard configuration

|

|

|

Chuck

|

Ф200 manual chuck

|

|

Tailstock

|

Manual tailstock

|

|

X axis ball screw

|

Domestic(Qishan)FD3210-889-1035

|

|

Z axis ball screw

|

Domestic(Qishan)FD2506-407-530

|

|

Electricity turret

|

4 position

|

|

X、Z axis screw bearing

|

Domestic(Derun)

|

|

Spindle bearing

|

Domestic P5

|

|

Machine casting

|

Highquality resin sand casting

|

|

Spindle assembly

|

Assembly spindle

|

|

Oil paint

|

Can be customized color

|

|

Lubrication

|

Domestic

|

Siemens Flat Bed Cnc Lathe Price CK6140 Horizontal Automatic Turning CNC Lathe Machine

◆This series of machine tools is a mature product mainly exported by Dalian DRC Machine Tool Co., Ltd. The whole machine has a compact structure, beautiful appearance, large spindle torque, high rigidity, stable and reliable performance, and excellent accuracy retention.

◆Optimized design of the headstock, suitable for turning of disc and shaft parts. It can process straight, arc, metric and inch threads, and multi-threaded. It is suitable for turning discs and shafts with complex shapes and high precision requirements. Parts Processing.

◆Both the machine tool guide rail and the sliding saddle guide rail adopt hard guide rails of special materials, which are super hard and wear-resistant, durable, and have good machining accuracy retention after high-frequency quenching.

◆Adopt domestic famous ball screw and high-precision screw bearing.

◆Each lubrication point adopts a forced automatic lubrication device for fixed-point and quantitative lubrication of the lead screw and guide rail. When there is an abnormal state or the amount of oil is insufficient, a warning signal is automatically generated.

◆The guide rail is equipped with a scraping device to prevent the guide rail from being corroded by iron filings and coolant, and to facilitate the cleaning of the iron filings.