Description

ELB SCHLIFF SWDE30H-NC – Year 1982 Upgraded 2001

CNC SURFACE GRINDER

Machine Brand : ELB SCHLIFF

Machine Model No.: SWDE30H-NC

New Date: 1982 / Upgraded 2001

We have the rear splash guards and motor guard that are not in the pictures

Column Type Design

Rated Grinding Range: 30″ x 120″

Work Area: 29-1/2″ x 138″

Grinding Wheel Size: 24″ Dia. X Up to 6″ Wide x 12″ Bore

Programmable Grinding Wheel Speeds: 100 to 1200 RPM

X Axis is Table Left & Right

Y Axis is Head Up & Down on Column

Z Axis is Head on Column In and Out

EQUIPPED WITH:

Fanuc 18i-M CNC 3 Axis Control New 2001, X – Y – Z

Upgrade work Done By GE Industrial Systems

25 Pin RS232 Comm Port

Can Do Creep Feed Grinding

Control Macros for Various Grinding Cycles

Cross Feed Incremental Grinding

(3) 24″ x 40″ OS Walker Electro Magnetic Chucks

(1) OS Walker Variable Power Control for All Chucks, Year 2000

O.S. Walker Chuck Controller Mounted to Main Electrical Panel

Sn. 101, Model Smart -150E, 230 Volts DC 65 Amps, Input 460 Volts, 60 Hz, Single Phase, 40 Amps

GE Variable Speed Model DV-300 Spindle Controller

Over The Wheel Motorized Wheel Dresser

Worm Gear to Rack Pinon Table Drive System X Axis CNC Controlled

(3) Grinding Wheel Hubs for Widths Up To 6″ Wide x 24″ Dia. x 12″ Bore with Adjustable Balance Weights

Central Automatic Lubrication System for All Ways

Grinding Spindle Rebuilt Mid 2017 by SKF

Spindle Chiller Unit

Hand Pulse Generator with 0.001″, 0.010″, 0.0001″ Increments for Each Axis

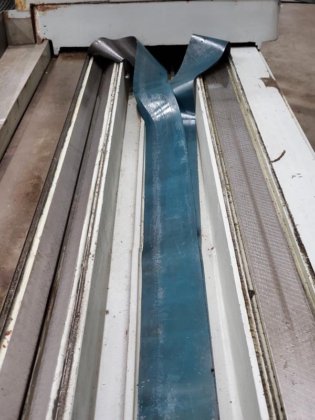

Way Covers for Each Axis

Ways for Each Axis are in Excellent Condition

Built In Over the Wheel Motorized Wheel Dresser with Diamond

Rate Overrides for Spindle, Feeds and Travels

(1) 75 KVA GE Drive Isolation Transformer, Multi Tap 482, 460, 438 Volts

Primary: 3 Phase 60 Hz 480 Volts Secondary: 230 / 133 Volts

Paper Filter Coolant System with Coolant Cooler

Floor Mounted Table Drive Servo Motor with Guarding

Coolant System Tank Capacity: 45″ x 100″ x 14″ Deep Approx. 270 Gallon

OEM Manual and Foundation Print and Original Operation Manual

Electrical Schematics for Upgrade System

20 – 48 KW (26.8 – 64.4 HP) Variable Speed DC Spindle Motor

Wired for 200 / 440 Volts 120 Amps

Overall Sizes of Machine Components:

Grinding Head and Way Assembly: 17,100 Lbs.

Bed Assembly with Control Console: 66″ FB (w/o servo motor) x 364″ (30.3′) Long x 71″ High x 22,250 Lbs.

Oil Cooler Unit: 29″ x 27″ x 49″ High x ? Lbs.

Lubrication Tank & Pump: 40″ x 29″ x 27″ High x ? Lbs.

Coolant Pump and Filter System: 61″ x 106″ x 45″ High x ? Lbs.

Electrical Control Panel with Chuck Control: 76″ x 26″ x 81″ High x ? Lbs.

Electrical Transformer: 32″ LR x 23″ FB x 36″ High x 505 Lbs.

Machine Fully Assembled is 339″ (28.25′) LR x 197″ FB x 165″ High (to floor, not on blocks)