Description

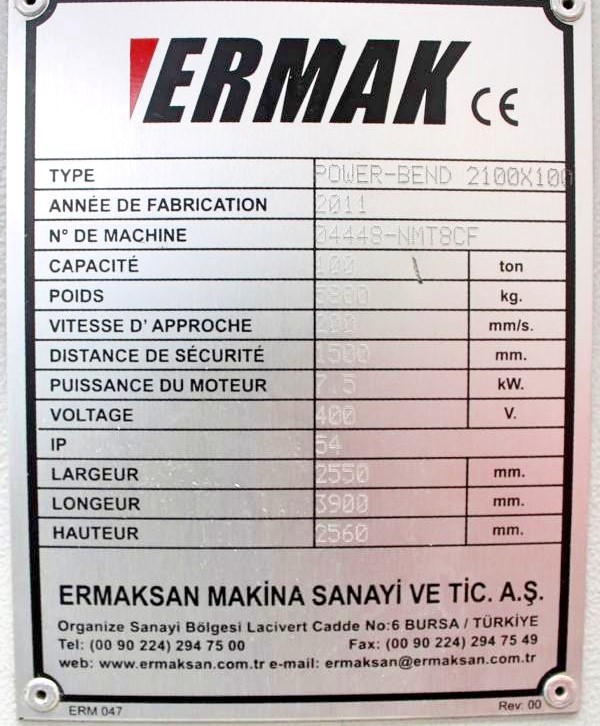

ERMAK POWER-BEND 2100X100 Press Brake – Year 2011

| Strength | 100 T |

| Folding length | 2100 mm |

| Distance between uprights | 1700 mm |

| CNC | ERMAK (CYBELEC) |

| Vertical stroke | 275 mm |

| Working speed | 10 mm/s |

| ERMAK POWER-BEND 2100X100 | Press Brake |

| Length x width x height | 3012.0 × 1960.0 × 2750.0 |

| Weight | 5800 kg |

TECHNICAL SPECIFICATIONS

pressure: 100 t

chamfer lenght: 2100 mm

distance between columns: 1700 mm

column arm: 410 mm

ram stroke speed: 200 mm/sec

work speed: 10.0 mm/sec

return speed: 165 mm/sec

work stroke: 275 mm

dayligth: 530 mm

table height: 900 mm

table width: 90.0 mm

oil volume: 150 ltr.

voltage: 400 Volt

total power requirement: 7.5 kW

weight: 5800 kg

range L-W-H: 3012 x 1960 x 2750 mm

DESCRIPTION

current new price ~ 55.000 euros

Special price on request

very well-maintained condition (!!)

Press brake with special equipment

increased installation height

increased cylinder stroke

as well as increased bending beam speeds

Furnishing:

– ERMAK (CYBELEC) CNC control, swiveling at the front left

High-resolution graphic color screen

Representation as a line, area or volume drawing of the product

Clear, concise menus in the operator’s language

large tools and products library)

– electro-motorized back gauge, on ball screws .. X = 800 mm

– CNC controlled axes Y1 – Y2 – X – axis

– ROLLERI deer foot upper tool – “PS 135.85-R08” with quick-change clamp

– Additional crowning device in the tool holder of the upper tool

– ROLLERI 4V die split – “M 460 R” with die shoe 60 mm

– BOSCH/HOERBIGER hydraulic components

– SIEMENS electrical system

– Light barrier behind the machine

– FIESSLER AKAS laser protection device, front

– 2x front support arms “sliding system”, with T-slot and tilting cam

– 1x freely movable double foot control

– left + right storage area for bending tools (homemade)

this extra information is standard for this model. Please always double-check the details during a visit

The ERMAK POWER BEND 2100X100 CNC Press Brake, produced in 2011, epitomizes precision and efficiency in sheet metal bending. With a pressure of 100 tons and a bending length of 2100mm, this machine offers exceptional versatility and performance for a wide range of bending applications.

Featuring a robust construction and advanced technical specifications, the POWER BEND 2100X100 ensures reliable and accurate bending operations. The increased installation height, cylinder stroke, and bending beam speeds make it suitable for handling various workpieces with ease.

Equipped with ERMAK (CYBELEC) CNC control, operators benefit from a high-resolution graphic color screen and clear, concise menus in their preferred language. The electro-motorized back gauge, CNC controlled axes, and additional crowning device in the tool holder of the upper tool enhance precision and efficiency in bending operations.

With specialized features such as the ROLLERI deer foot upper tool and 4V die split, along with high-quality BOSCH/HOERBIGER hydraulic components and SIEMENS electrical system, the POWER BEND 2100X100 ensures consistent and high-quality bending results. Safety features including a light barrier and FIESSLER AKAS laser protection device further enhance operator safety during operation.

Overall, the ERMAK POWER BEND 2100X100 CNC Press Brake offers unmatched performance, precision, and reliability, making it an essential tool for metalworking operations requiring precise and efficient sheet metal bending.