Description

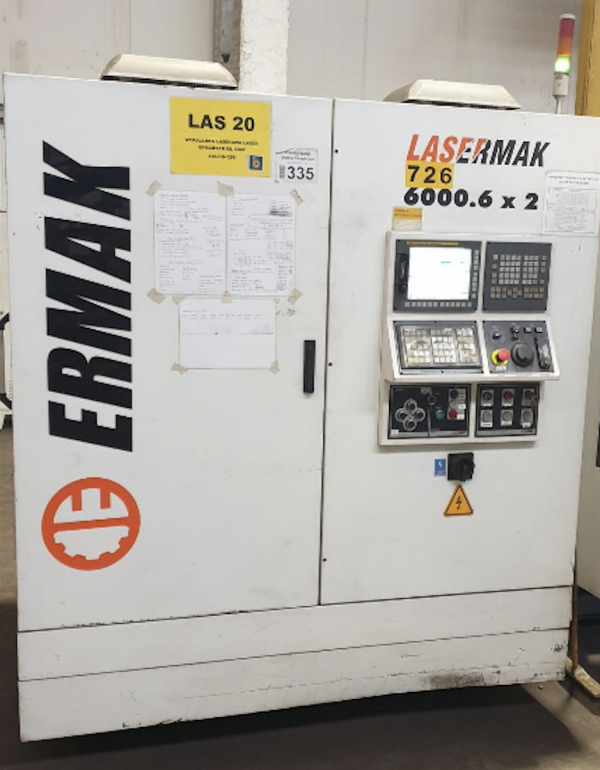

Ermaksan Lasermak 6000 6X2 – Year 2014

laser cutting machine

| Metal length | 2000 mm |

| Power | 6000 W |

| Metal width | 6150 mm |

| Type | CO₂ |

| Option to cut tubes | no |

| Max thickness | 25 mm |

| CNC | yes |

| CNC type | GE Fanuc C6000i-Model C |

| Travel X | 6200 mm |

| Travel Y | 2050 mm |

| Travel Z | 150 mm |

| Max weight of the workpiece | 4000 kg |

| Ermaksan Lasermak 6000 6X2 | |

| Weight | 1300 kg |

ERMAKSAN LASERMAK 6000 6X2 laser was built in 2014. The laser cutter has a GE Fanuc C6000i-Model C CO2 laser source with a power of 6000 W and a wavelength of 10.6 μM.

It enables processed sheets with a thickness of 15 mm (stainless steel), 25 mm (black steel) or 12 mm (aluminum).

The maximum weight of the sheet to be cut is 4000 kg, and the size is 2000×6150 mm.

The laser gas consists of CO2, He and N2, and its consumption is approximately 20 liters / hour. The GE Fanuc series 31i-LB CNC control allows the programming of five axes (X, Y, Z, U and V).

The laser is equipped with, among others, LANTEK CAD / CAM software, as well as a LASERMACH cutting head.

In addition, the instrumentation also includes an electric shutter, a warning lamp and an hour meter showing the total number of hours the exhaust pump has been running.

Technical data of the ERMAK LASERMAK 6000 6X2 laser cutter

– laser source: 6000 W CO2-laser GE Fanuc C6000i-Model C

– maximum sheet size: 6150 x 2000 mm

– maximum workpiece weight: 4000 kg

– maximum sheet thickness: ordinary steel 25 mm (during tests the maximum achieved: 30 mm), stainless steel 15 mm, aluminum 12 mm

– RF: 2 MHz

– power stability: ± 2% (power monitor)

– laser wavelength: 10.6 μM

– beam mode: Fanuc Low Order Mode

– laser shutter: mechanical safety shutter

– laser gas composition: CO2 / He / N2

– gas consumption by laser: 20 l / h

– coolant flow rate: 250 l / min

– total energy requirement: 100-120 kW

– cutting head focal length: 5 “-7” -10 “inch

– machine axes: 5 axes [X, Y, Z, U (X2), V]

– axis movement range: X and U axes – 6200 mm, Y axis – 2050 mm, Z axis – 150 mm, V axis – 4000 mm

– accelerations: X axes, U – 2 G, Y axis – 3 G, Z axis – 2 G

– maximum axis speeds: 170 m / min (simultaneous) (speed of single axes X and Y 120 m / min)

– positioning accuracy: ± 0.03 mm / min

– repeat accuracy: ± 0.015 mm

– shuttle table (automatic unit loading and unloading): 2 pallets (65 sec)

– supporting gas: ordinary steel – oxygen (0.5-6 Bar), stainless steel – nitrogen (0.5-25 Bar), aluminum – dry air or nitrogen (0.5-25 Bar)

– cutting head: LASERMECH

– CAD / CAM software: LANTEK CAD / CAM

– CNC controller and operator panel: GE Fanuc series 31i-LB (“LCD mounted” CNC with 10.4 “color screen, 512kB memory and all relevant laser functions, Ethernet, keyboard)

– machine dimensions (length x width x height): 18 820 x 7005 x 2280 mm

– machine weight: 36500 kg

Characteristics of the oscillator – C6000i-C

– type: C6000i-C

– method: high-speed axial CO2 laser excited by high-frequency discharges

– structure: integrated mode (oscillator and power supply)

– laser power: 6000 W

– peak pulse value: 7000 W

– laser wavelength: 10.6 μM

– bundle diameter (exit): fi 28 mm or less

– 90 degree linear polarization

– pulse output frequency: 5 to 2000 Hz

– Pulse output command duty ratio: 0 to 100%

– laser gas: composition – mixture of CO2: He: N2 composition ratio respectively – 5 ۪, 25%: 60 ۭ .00%: 35 ۫ .75% gas pressure – -175 ۪, 025 MPa (0.15 – 20 MPa) consumption measured on the gauge – about 20 l / h

– coolant: quantity – 125 l / min or more temperature – 20 – 30 degrees water temperature stability – ± 2 degrees C (for laser output stability 2%) circulating water pressure – 0.5 MPa or less on the gauge recommended cooling capacity – 66 kW or more

– power requirements: 200 VAC + 10%, -15%, 50/60 Hz or 220 VAC + 10%, -15%, 60 Hz ۫ Hz or 230 VAC + 5%, -10%, 60 Hz ± 1 Hz

– required input power: 75 kVA

– maximum current: 255 A.

– hour meter: total number of hours the exhaust pump has been running

– electric shutter: included

– warning lamp: flashes during discharging (optional)

– weight: approximately 1,300 kg