Description

FABERTEC FL4 1530 – Year 2021

Condition : New

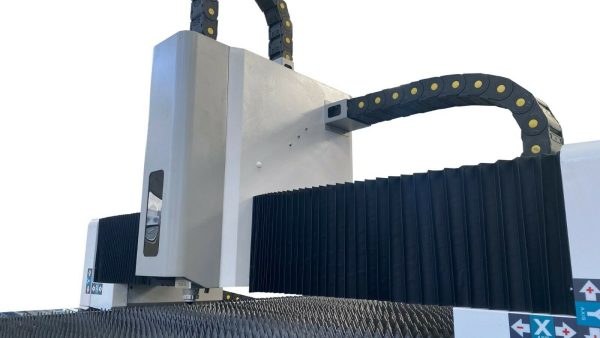

FABERTEC FL 4 FIBER LASER

2 retractable tables, fully walled for safety

For over 20-30 years since mass produced fiber lasers appeared in metal fabricators workshops

the entry price for those machines was insanely high as it happens with all new technologies.

Just 10 years ago the 1kW entry model from TRUMPF, AMADA or BYSTRONIC would set you

€200-300k. As the technology moved forward and lots of firms started to invest in fiber source manufacturing facilities the cost of parts starts to drop quite significantly even to a point where metal fabricator can start with rapid metal cutting FABERTEC FL2 1kW for only £36k+VAT.

It was never so easy to enter into the metal cutting market as it is at the moment, with more high powered fiber lasers costing less than £100k, but allowing you to cut 15-25mm mild steel or

15mm stainless steel, not to mention aluminium, brass or copper.

As with every FABERTEC machine we offer a full package with clear pricing without any hidden extras. All our prices include delivery on curtain lorry, whole setup package, software, installation and training. We believe in transparency and quick turnover as we know from past experience as fabricators you do not have time and patience for lengthy quotations, small variations or extras which very often can rise the price by even 50%.

The important factor in choosing a fiber laser cutting machine is that it is almost maintenance and parts free. Most of the laser sources last up to 100,000 hours without the need of calibrating and renewing generators and the only spares used are lenses/lens protectors, nozzles and they do

not cost a fortune.

Fiber Lasers for metal cutting are really a no brainer solution for companies which want to produce thousands of parts in literally a few days.

STARTING FROM £70k+VAT 2kW 1530

FL4 is made to streamline your operations and contain metal particles in an enclosed area.

Also, it comes as standard in the minimum 1500 x 3000mm table size and is fitted with 2 tables on a conveyor system.

This allows the operator to cut on one table where the 2nd is retracted to rear of the machine allowing for easy parts clearing and loading new sheet by forklift, or magnetic or clamp crane.

Also by keeping the laser operations enclosed you can position FL4 anywhere in the workshop

not worrying about covering or building partitions like with FL2. We highly recommend to invest

in one of the metal dust extractors when you choosing FL4.

Fiber lasers are used to cut carbon steel, stainless steel, aluminium, brass and copper.

The thickness of the material dictates what fiber laser power you should use.

The most affordable 1kW lasers can cut up to 6-7mm mild steel. By upgrading the laser power you can not only cut thicker materials, but also increase speed of your operations on thinner materials as the laser head will move much quicker with a more powerful beam.

To get the most of your fiber laser investment you should use gas assisted cutting, as this will greatly improve (or in some cases even allow to cut) your edge finish and lack of dross.

For cutting highly reflective metals like brass, copper, aluminium, we strongly recommend IPG laser source instead of budget Raycus.

Also, cutting thicknesses table dependable on power.

2KW MAX/RAYCUS LASER SOURCE AUTOMATIC FOCUS

MODEL

FABERTEC FL4 1530 2kW Max/Raycus

FABERTEC FL4 2030 2kW Max/Raycus

FABERTEC FL4 2040 2kW Max/Raycus

FABERTEC FL4 2060 2kW Max/Raycus

TABLE DIMENSIONS

1500 x 3000mm (2 tables)

2000 x 3000mm (2 tables)

2000 x 4000mm (2 tables)

2000 x 6000mm (2 tables)

LASER UPGRADE EXTRA IPG GERMAN SOURCE

AUTO FOCUS

2kW IPG German Source

3kW IPG German Source

4kW IPG German Source

6kW IPG German Source

LASER POWER UPGRADE EXTRA AUTO FOCUS

3kW Max/Raycus Laser

4kW Max/Raycus Laser

6kW Max/Raycus Laser

TECHNICAL SPECIFICATION FABERTEC FL 4 FIBER LASER:

Max/Raycus or German IPG laser source – advertised manufacturers fiber laser lifespan

up to 100,000 hours – equivalent of 10h daily cutting for 27 years!

Structure fully welded and heat destressed

Full servo motors Fuji or Yaskawa installed

Speeds up to 80 meters per minute

Aluminium reinforced gantry for higher speeds

Hiwin runners with automatic lubrication

Automatic height adjustment – laser heads follows sheet height on the table

Automatic calibration – the controller automatically checks laser settings

Large monitor with Cypcut software

Handheld wireless control panel

Draw, adjust, import DXF/PDF, create lead

in/out – all straight from the machine

Two separate inlets for oxygen/nitrogen controlled by electric valves

Automatic focus of laser head from software