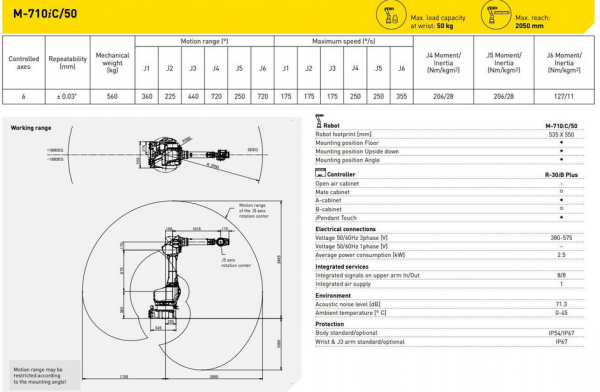

Description

Fanuc M-710iC/50 Industrial Robot

Y.O.M. 2017

| Number of axis | 6 |

| Reach in mm | 2050 mm |

| Payload in kgs | 50 kg |

| Control type | FANUC R-30iB Plus |

| Fanuc M-710iC/50 Industrial Robot | |

| Weight | 560 kg |

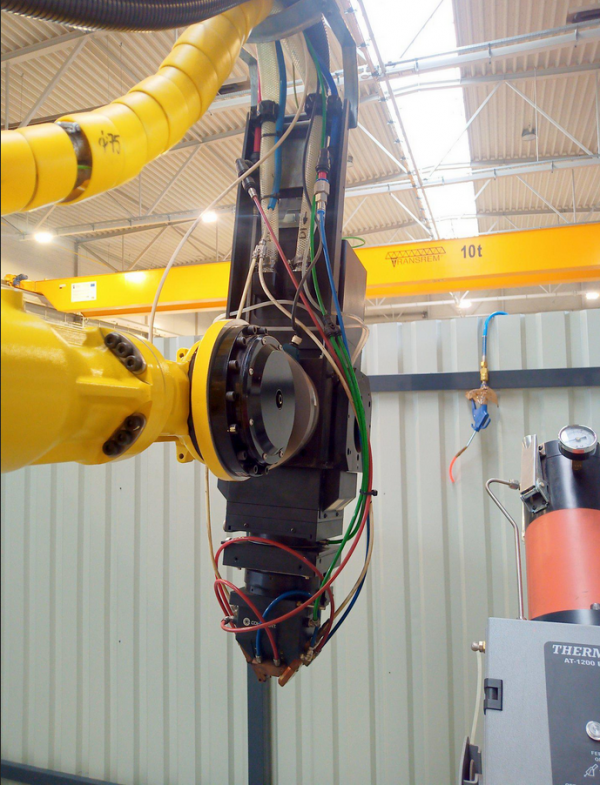

The robotic hardfacing station with the FANUC M-710iC / 50 robot is designed to perform the surfacing process – covering the surface of molten metal objects with a powder coating in order to supplement defects in the detail or to give it new features.

The robotic hardfacing station includes:

1. Robot: FANUC M-710iC / 50

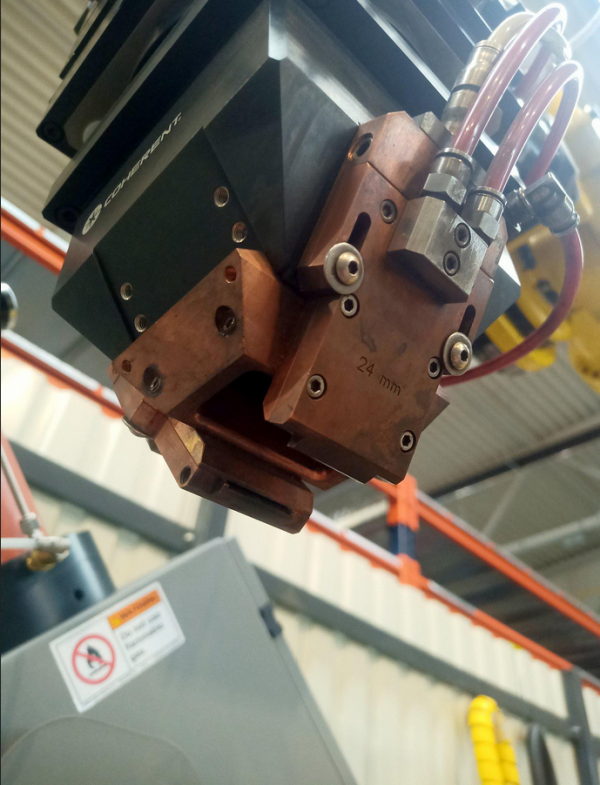

2. Laser head: COHERENT HighLight D-Series 10 kW

3. Laser head driver: COHERENT HightLight 10000D

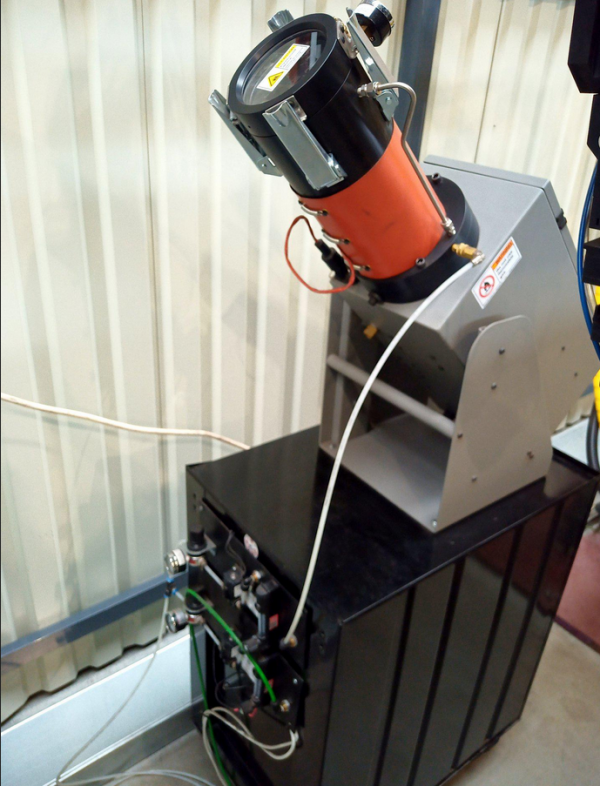

4. Powder feed unit: THERMACH INC. AT-1200 POWDER FEEDER

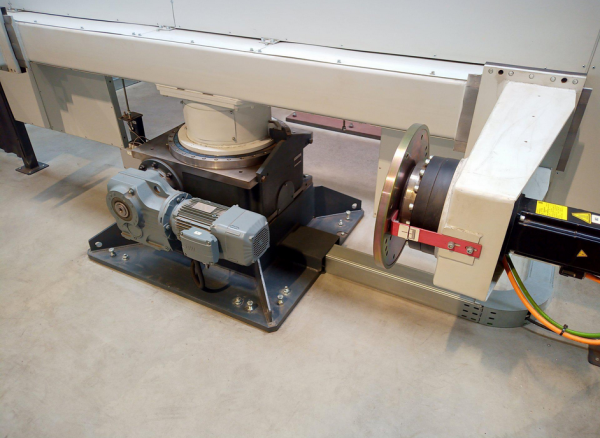

5. Rotary table consisting of TAKOMAT RT400 turntable and FANUC motors

6. Chiller: RIEDEL PC 321.2H6LE.I

Extremely light welding robot with a durable body that is completely resistant to water and dust, ideal for processing uncomfortable objects with irregular shapes. The small dimensions of the M-710iC / 50 welder allow it to be mounted in any position in a small space, making the machine very universal. High axial speed in combination with a rigid arm with a reach of 2050 mm and a lifting capacity of 50 kg, ensure very fast movement of all kinds of objects.

The mounted FANUC R-30iB Plus controller with over 250 software functions helps to maximize the performance of the industrial robot in terms of cycle time, speed, accuracy and safety. Full connectivity via Ethernet also allows easy connection of robots, remote computers and other types of equipment with the controller.

The COHERENT HightLight 10000D laser head controller provides both high power, up to 10 kW, as well as an increased range of the shape of the laser beam, making the device ideal for applications related to heat treatment, plating and welding. The COHERENT HighLight D-Series 10 kW laser head with a unique design enables a wide range of output beam size options that will not limit the current application.

THERMACH INC. Powder feeder. AT-1200 POWDER FEEDER is characterized by high precision of workmanship, digital control and durable construction, ensuring full use of the device for many years. Metric feed rates ensure very high accuracy (± 2% / min) and repeatability. The operator of the powder feed unit can control the wheel speed and other parameters of the machine manually or remotely via a PLC or computer.

The welding cell also has a TAKOMAT RT400 rotary table equipped with FANUC motors, converting uniform inbound motion into intermittent outbound motion. The RIEDEL PC 321.2H6LE.I chiller with a cooling capacity of 30 kW is responsible for ensuring the appropriate temperature of the machine, the workpiece, as well as the entire production line.

Technical data of the FANUC M-710iC / 50 industrial robot

– year of production: September 2017

– controller: FANUC R-30iB Plus

– number of axles: 6

– maximum lifting capacity: 50 kg

– maximum reach of the arm: 2050 mm

– range of movements: 250 °

– maximum speed of movements: 250 ° / s

– repeatability: ± 0.03 mm

– moment of inertia: 206/28 Nm / kgm2

– integrated air supply

– dimensions of the robot’s base (L x W): 535 x 550 mm

– assembly: floor, at an angle, upside down

– noise level: 71.3 dB

– ambient temperature: 0-45 ° C

– average power demand: 2.5 kW

– power supply: 380-575V 50/60 Hz

– weight: 560 kg

Specification of the COHERENT HightLight 10000D laser head driver

– year of production: 2018

– power: 10 kW

– laser beam length: 975 ± 10 nm

– working length: 275 mm

– minimum pulse width: 3 ms

– power stability: <2% / h

– maximum repetition frequency: 300 Hz

– line beam options: 4,5,6,12,18,14,30 mm

– full load current: 3×80 A

– power supply: 3×400 V; 50/60 Hz

– dimensions (L x W x H): 586 x 850 x 1360 mm

– dimensions of the COHERENT HighLight D-Series 10kW laser head (length x width x height): 190 x 283 x 201 mm

Characteristics of the THERMACH INC. Powder feed unit. AT-1200 POWDER FEEDER

– rotational speed: 25 rpm

– speed regulation

– capacity: 3359 ml

– maximum pressure: 90 PSI

– feeding accuracy: ± 2% / min

– remote control

– power supply: 115/230 VAC; 50/60 Hz

Technical parameters of the TAKOMAT RT400 turntable

– year of production: 2018

– output flange diameter: 460 mm

– hole diameter: 110H8 mm

– number of indices: 2,3,4,6,8,10,12,16,20,24,30,36

– maximum number of cycles: 145 / min

– height: 316 mm

– weight: 325 kg

Characteristics of the RIEDEL PC 321.2H6LE.I chiller

– year of production: 2014

– cooling capacity: 30 kW

– operating range (ambient temperature): from +5 to -40 ° C

– working range (coolant temperature): +12 to + 20 ° C

– maximum operating pressure: 20.2 bar

– power demand: 12.3 kW

– power supply: 3×400 / 460 V; 50/60 Hz

– dimensions (L x W x H): 1541 x 874 x 1755 mm

– weight: 460 kg