Description

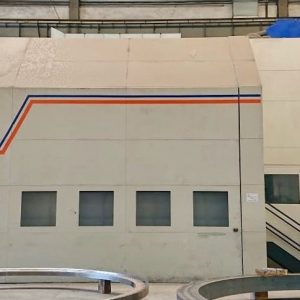

FELLOWS 70-15 – Year 1989

Heavy Duty Internal/External Gear Shaper

| Manufacturer | FELLOWS |

| Model | 70-15 |

| Condition | Used |

| FELLOWS 70-15 | Hobbing Machine |

| Heavy Duty Internal/External | Gear Shaper |

| Maximum diameter external gear cut (nominal) | 70” (1778MM) |

| Maximum diameter internal gear cut (nominal) | 88” (2235MM) |

| Maximum diameter workpiece accommodated | 104” (2642MM) |

| Worktable diameter | 84” (2133.6MM) |

| Max permissible weight of workpiece & fixture | 36,000 LBS(16,500 KGS) |

| Of cutter spindle | 0” (0MM) |

| Uppermost position | 28” (711.2MM) |

| Maximum diametral pitch (full length teeth) | 2 DP (12.5 MODULE) |

| Maximum diametral pitch (stub teeth) | .75 DP (24.5 MODULE) |

| Maximum diameter pitch (30°p.a. splines) | 2-5/5 DP (11 MODULE) |

| Diameter of cutter spindle | 6.25” (158.75MM) |

| Maximum stroke length | 19.118” (485.6MM) |

| Maximum face-width (nominal) | 15” (381MM) |

| Stroking speeds (infinitely variable) | 5 TO 122 S.P.M. |

| Maximum infeed of cutter ram | .0020 INCH/MIN (.0509MM/MIN) |

| Minimum infeed of cutter ram | .0005 INCH/MIN (.0127MM/MIN) |

| Max rotary feed per stroke (per 1″ of cutter diameter) | .0068 INCH/MIN. (.1727MM.MIN.) |

| Min rotary feed per stroke (per 1″ of cutter diameter) | .0006 INCH/MIN. (.0152MM.MIN.) |

| Machine overall length | 192” (4877MM) |

| Machine overall depth | 144” (3657MM) |

| Machine overall height | 150″ (3810MM) |

| Machine net weight (approximate) | 95,000 LBS.(43,182 KGS) |

70-15 FELLOWS HEAVY DUTY INTERNAL/EXTERNAL GEAR SHAPER

MODEL 70-15

SUITABLE FOR THE MANUFACTURE OF EXTERNAL STRAIGHT SPUR GEARS UP TO 70” (1778MM) PITCH DIAMETER,

AS WELL AS INTERNAL SPUR GEARS AND SPLINES WITHIN

A RANGE OF 0” TO 88” (2235MM) PITCH DIAMETER,

REGARDLESS OF SHAPER-CUTTER RADIUS.

THIS UNIQUE FEATURE, COMBINED WITH THE MACHINE’S

15” (381MM) FACE-WIDTH CAPACITY, AND 1.7 DP

(14.9 MODULE) CUTTING CAPABILITY IN STEEL,

PROVIDE A FORMIDABLE PLATFORM FOR PRODUCING A

WIDE RANGE OF LARGER GEARED PART MEMBERS.

EQUIPMENT / FEATURES:

MASSIVE MACHINE MAIN BASE WITH WORK-TABLE, UPPER

COLUMN, CUTTER RAM AND SLIDE OF “SUPER ROBUST”

CONSTRUCTION

MACHINE WITH “SADDLE BACKOFF” METHOD OF CUTTER

relieving

HEAVY DUTY CUTTER SPINDLE 6.25” (158.75MM)

DIAMETER WITH STANDARD STRAIGHT SPUR GUIDE

CUTTER POSITIONING VIA STROKE JOG-BUTTON

RAPID ROTATION OF WORK SPINDLE FOR TRUEING WORK-PIECE

T-SLOTTED WORK TABLE WITH CENTER BEARING CAP (OR ???”

DIAMETER BORE)

RAPID SADDLE TRAVERSE FOR TRAVERSING SADDLE RELATIVE

TO WORK AUTOMATIC DEPTH FEED MECHANISM FOR ONE TO

FOUR CUTS, WITH 4-SPEED MOTOR PROVIDING SPEED

CHANGE ON FINISHING CUT

ASSORTED WORK AND FEED CHANGE GEARS

ASSORTED STROKE CHANGE GEARS

ONE (1) CUTTER ADAPTOR

RISER PLATE OF 2” (50.8MM) HEIGHT

MAIN DRIVE MOTOR 15 HP, 650/2200 RPM, 240

VOLT 60 HZ W/WESTINGHOUSE RECTIFIER UNIT FOR AC

POWER FORCED LUBRICATION TO ALL WORKING ELEMENTS

WITH “LUBRIQUIP MULTI-PURPOSE LUBRICATION

CONTROLLER”

COOLANT TANK,

PUMP,

PIPING,

WITH CHIP PAN

FULL COMPLEMENT OF ELECTRICS,

(MOTORS/CONTROLS)

ASSORTED GUARDS, COVERS