Description

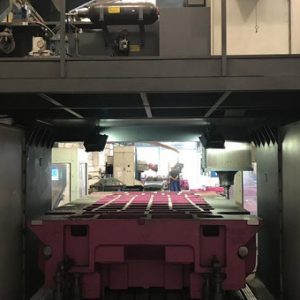

FPT Dino Spin CNC 5-Axis Double Column Bridge Type Gantry Vertical Machining Center – Year 2020

CAPACITY:

X-Axis Travel 2500 MM

Y-Axis Travel 3500 MM

Z-Axis (Ram Stroke) 1300 MM

C Axes, Swivel +/- 270 Degrees

A-Axis, Swivel Range +/- 115 Degrees

Table Size 2500 MM x 3500 MM

Spindle Speeds 22,000 RPM

Spindle Taper HSK-A63

Spindle Drive Motor 44 KW / 54 KW

Feeds 39980 MM/MIN

Equipped With:

Heidenhain TNC 640 5-Axis CNC Control

2-Axis “Electro Spindle” Programmable Swivel Head

60-Position Automatic Tool Changer

Through Spindle Coolant

Chip Conveyor

Compressed Air Thru Spindle

Full Guarding Enclosure

Control Details:

Dynamic RTCP Software

RAM: 4 GByte

32 Gbyte Hard disk with min 21 Gbyte program memory

Input resolution and display step:

Linear axes up to 0,1 µm

Angular axes up to 0,0001°

Input range:

max +/- 99999,9999 mm (+/-3937 in.) or +/- 99999,9999°

Interpolation:

Circular interpolation in 3 axes with rotated working plane

Helical interpolation: superimposition of circular and linear path

Linear in 5 axis (version subject to export license)

Block processing time:

0,5 ms (3D straight line without radius compensation)

Axis feedback control

Position loop resolution: signal period of the position encoder/1024

cycle time of position controller: 200 µs

cycle time of speed controller: 200 µs

current controller cycle time: min. 100 µs

Data interfaces:

1 x RS-232-C

2 x Ethernet 1000BaseT (Twisted Pair Ethernet)

1 x frontal USB 2.0

4 x rear USB 3.0

Note:

Inspect In Plant Under Power!

Features:

Heidenhain TNC 640 CNC Controls

2-Axis “Electro Spindle” Programmable Swivel Head

Through Spindle Coolant

60-Position Automatic Tool Changer