Description

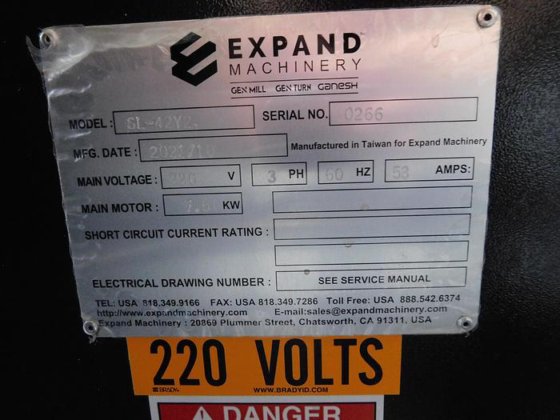

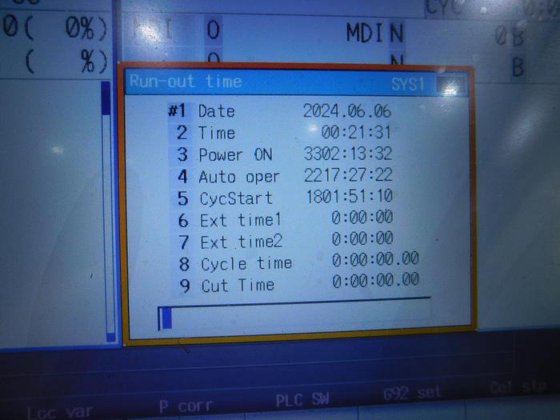

Ganesh Gen Turn SL-42Y2 HYBRID 42 MM 8-Axis CNC Swiss Machine – Year 2021

Make: Ganesh Gen Turn

Model: SL 42 Y2

SN: 0266

Year: 2021

Control: Mitisubishi

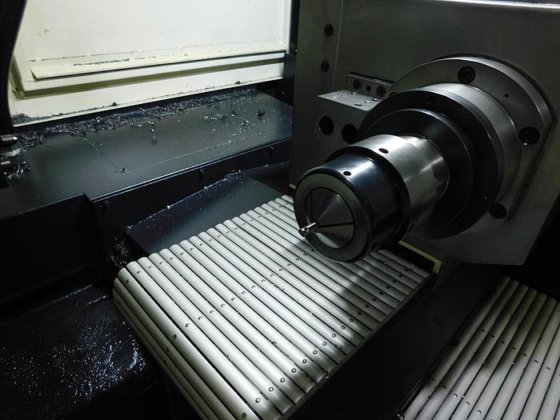

MAIN SPINDLE

Spindle Speed Max: 6,000 rpm

Spindle Motor:

10 HP (15 min)

7.5 HP (Constant)

Collet Style for Main & Subspindle: Traub-42 / 173E

Collet Closer Style: Lever Action

Bar Diameter, w/o guide bushing: 1-5/8″ (42mm)

Maximum Turning Length: 4.13″ (105mm)

Spindle Bore Diameter: 1.732″ (44mm)

SUB-SPINDLE

Speed: 6,000 rpm

Spindle Bearing:

Quad Duplex Pair

Main Spindle Servo Motor:

10 HP (15 min)

7.5 HP (Constant)

Collet Style:

Traub-42 / 173E

Max. Barstock Diameter: 1-5/8″ (42mm)

Spindle Bore Diameter: 1.732″ (44mm)

Maximum Workpiece Length for Front Ejection: 110mm

AXIS

Main Spindle Stroke: 12.20″ (310mm)

Rapid Traverse Rate, X/Y/Z-1, X/Y/Z-2: 944 ipm (24 m/min)

X1, Z1 Axis Motor Power: 2 HP (1.4 kw)

X2, Y1, Y2, Z2 Axis Motor Power: 1 HP (.75 kw)

X1, Y2 Linear Ways: Ball Bearing

X2, Y1, Z1, Z2 Linear Ways: Roller Bearing

Machine Dimensions: 121″x67″x83″

Power Requirements: 220 Volt, 60 Hz, 3-Phase, 80 Amps, 30 kVA

Air Requirement: 85 psi @ 6 cfm

Features:

Bar Capacity to Ø1-5/8”,

3-Bank Axial Live Tool,

Double “Y” Axis and Double “C” Axis,

Simultaneous Main & Sub-Spindle Machining,

30-Tools with 8-Driven Tools, Standard

Parts Conveyor,

Chip Conveyor,

2021 Mistbuster 850 Filtration and

2021 Edge 193” Bar Feeder.

Why do Customer prefer Ganesh Gen Turn SL-42Y2 HYBRID 42 mm 8-Axis CNC Swiss Machine?

MAIN SPINDLE

|

Maximum RPM / Spindle Bearing |

6,000 RPM / 5 Bearing Spindle, 3 Front, 2 Rear Ball Bearings |

|

Main Spindle Servo Moto (5.5 / 7.5 kw) |

10 HP 15 min Duty Rated (7.5 HP Constant Duty Rated) |

|

Collet Style for Main & Subspindle |

Traub-42 / 173E |

|

Collet Closer Style |

Lever Action Collet Closer – Driven by Hydraulic Piston |

|

Guide Bushing Type |

Optional Rotary Guide – Bushing uses Hardinge STM38 Bushings |

|

Bar Diameter |

Ø1/4” – 1-5/8” (Ø5 – 42 mm) without Guide Bushing |

|

Maximum Turning Length (Rotary Bushing) |

12.20” Single Stroke (310 mm) (Rotary Guide Bushing Optional) |

|

Maximum Turning Length (without Bushing) |

4.13” (105 mm) |

|

Spindle Bore |

Ø1.732” (Ø44 mm) |

MAIN SPINDLE TOOLING

|

OD Turning Tool Holders – S1 |

6 – 16 mm (5/8”) Square Shank Tool Holders |

|

|

ID Internal Tool Holders – S1 |

5 – 25 mm Shank Round Tool Sleeve Bores |

|

|

ID Deep Hole Drill Positions – S1 |

2 – 25 mm Shank Round Tool Sleeve Bores |

|

|

Cross Slide Live Tools – S1 |

6 – ER-20 Collet Chuck Spindles, 4,000 RPM, 2 HP (1.6 kw) |

|

|

Axial Front Slide Live Tool Option – S1 |

3 – ER-20 Front Axial Live Tools – Optional in lieu of 1 Cross Tool |

|

|

Maximum Drilling / Tapping Capacity |

13 mm Drilling / M10 Tapping |

|

|

Cross Drilling / Tapping Capacity Option |

10 mm Drilling Capacity / M6 Tapping |

SUB-SPINDLE

|

Sub-Spindle RPM / Spindle Bearing |

6,000 RPM / 4-Bearing – Quad Duplex Pair Configuration |

|

Main Spindle Servo Moto (2.2 / 3.7 kw) |

10 HP 15 min Duty Rated (7.5 HP Constant Duty Rated) |

|

Collet Style for Main & Subspindle |

Traub-42 / 173E |

|

Maximum Barstock Diameter |

1-5/8” (42 mm) (42 mm Parts can Through the Subspindle) |

|

Spindle Bore |

Ø1.732” (Ø44 mm) (uses Hydraulic Piston Lever Action Collet Closer) |

|

Finished Parts Ejector & Air Blast |

Included |

|

Maximum Workpiece Length for Front Ejection |

110 mm Maximum Part Length for Front Ejection from Subspindle |

SUB-SPINDLE TOOLING

|

OD Turning Tool Holders – S2 |

3 – 16 mm Square Shank Turning Tool Holders |

|

ID Internal Tool Holders – S2 |

5 – 25 mm Shank Round Tool Sleeve Bores |

|

ID Internal Tool Holders – S2 (8 possible) |

3 – ER-16 Fixed Tools – Ø3/8” Max. |

|

Subspindle Axial Live Tools – S2 (8 possible) |

3 – ER-16 Axial Live Tools, 4,000 RPM, 1.0 HP (0.75 kw) |

|

(8-subspindle tool block can mix live & fixed tools, or 2 radial live tools can be substituted for 2 axial tools on subspindle tool block) |

|

|

Maximum Drilling / Tapping Capacity |

13mm Drilling Capacity / M10 Taping on Sub-Spindle |

|

Maximum Cross Drilling / Tapping Capacity |

8mm Drilling Capacity / M6 Tapping |

AXIS

|

Main Spindle Stroke |

12.20” (310 mm) |

|

X1, Y1, Z1, X2, Y2, Z2 Rapid Traverse Rate |

944 IPM (24 m / min) |

|

X1, Z1 Axis Motor Power |

2 HP (1.4 kw) |

|

X2, Y1, Y2, Z2 Axis Motor Power |

1 HP (.75 kw) |

|

X1, Y2 Linear Ways |

Ball-Bearing Linear Ways (Point Contact) |

|

Z2, Y1, Z1, Z2 Linear Ways |

Roller-Bearing Linear Ways (Line Contact – Twice as Rigid) |

|

Minimum Input Unit |

0.0001” (0.001 mm = 40 millionths/inch) |

SPECIFICATIONS

|

Machine Dimensions (L x W x H) |

121” x 67” x 83” (2,925 x 1,690 x 2,100) + 29” for Conveyor |

|

Machine Weight |

11,024 lbs. (5000 kgs) |

|

Coolant Pump Power |

1-3/4 HP (1.3 kw) with Flow Confirmation Monitor |

|

Coolant Tank Capacity |

65 gallon Coolant Tank (250 L) (Cutting Oil Only, No Coolant) |

|

Lubrication Distribution (2-liter Capacity) |

Way Lube Distributed at 3 – 6 cc / 15 min Cycle |

|

Machine Power Requirements |

220 vac ±5%, 80 amps, 30 kVA, 3 phase, 60 Hz |

|

Air Requirements |

85 PSI at 6 CFM for Parts Catcher, Parts Ejector, & Air Blast |