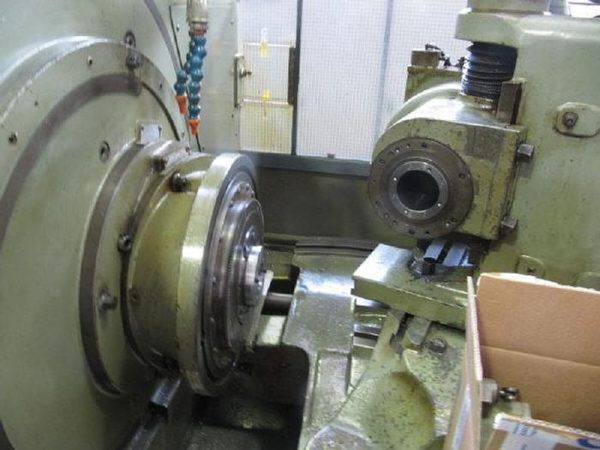

GLEASON 116 Hypoid Spiral Gear Hobber

Contact us for price

Description

GLEASON 116 Hypoid Spiral Gear Hobber

| Model | 116.0 |

| Condition | Used |

| SUITABLE FOR | THE CUTTING OF HYPOID AND SPIRAL BEVEL GEARS AND PINIONS |

| GLEASON 116 Hypoid Spiral | Gear Hobbing |

| Maximum full depth | 1″ (25.4MM) |

| Cone distance, maximum | (30-DEGREE |

| Sprial angle & 12″ diameter cutter | 9″ (230MM) |

| Maximum pitch angle (shafts at 90-deg) | 84 DEGREES 18′ |

| Minimum pitch angle (shafts at 90-deg) | 5 DEGREES 42′ |

| Extreme ratio (shafts at 90-deg) | 10 TO 1 |

| Operate with “formate” gears | 2 TO 1 |

| 10 to 1 ratio | 18″ (460MM) |

| 2 to 1 ratio | 16″ (406MM) |

| 1 to 1 ratio | 12.75″ (324MM) |

| Maximum face width (depending on cutter) | 2.75″(78MM) |

| Max./min. number of teeth | 175 TO 5 |

| Work spindle taper bore dia.(large end) | 3.9″(100MM) |

| Depth of taper | 6″(150MM) |

| Diameter of hole through spindle | 3.06″(78MM) |

| Diameter of spindle nose | 5.5″(140MM) |

| Cutter diameters utilized | (150,190,230,305MM) |

| Workhead max offset above center | 4.5″ (114MM) |

| Workhead max offset below center | 4.5″ (114MM) |

| To nose of spindle | 2.5″ (63MM) |

| Cutter speeds | 20 TO 115 RPM |

| Feeds (seconds per tooth) | 9 TO 80 SECONDS |

| Feed motor | 5 HP 1800 RPM |

| Hydraulic motor | .75 HP 1800 RPM |

| Coolant motor | .5 HP 3600 RPM |

| Floor space | (1905X2896MM) |

| Machine net weight | (10,773 KGS) |

EQUIPMENT / FEATURES:

HYDRAULIC DOUBLE-ACTING CHUCKING MECHANISM

WITH DRAW-IN BAR & NUT

CAM # 43210960 (JOBBING)

LATER GENERATION HYDRAULICALLY ASSISTED BRAKE

MECHANISM FOR CLAMPING OF WORK-SPINDLE

MODIFIED ROLL WITH YOKE

CUTTER-HEIGHT GAUGE

STOCK-DIVIDING GAUGE

CUTTER TRUING GAUGE

CUTTER TRAMMING DEVICE W/HAND-WHEEL

GLEASON AUTOMATIC COUNTER AND STOP

FULL COMPLEMENT OF ELECTRICS (MOTORS/CONTROLS)

SELF CONTAINED HYDRAULIC SYSTEM

SELF CONTAINED COOLANT SYSTEM

GUARDS, COVERS

FULL SET OF CHANGE GEARS WITH TOOL & GEAR CABINET

MISC. OPERATOR’S TOOLS, SPANNERS, WRENCHES, ETC.

MODEL NO. 116 GLEASON HYPOID SPIRAL

BEVEL JOBBING GENERATOR, (ROUGHER/FINISHER),

SUITABLE FOR THE CUTTING OF HYPOID AND SPIRAL BEVEL

GEARS AND PINIONS UP TO 18″ (460MM) PITCH DIAMETER

10:1 RATIO, 9″ (228.6MM) CONE DISTANCE MAXIMUM

OF 2 DP (MODULE 12.7)