Description

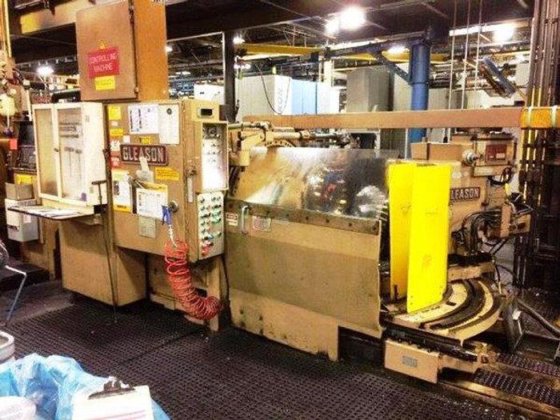

GLEASON 650 Hypoid Spiral Bevel Gear Generating Machine – 1978 Model

NEW IN 1978

SUITABLE FOR THE CUTTING OF LARGER SPIRAL BEVEL, HYPOID,

AND ZEROL BEVEL PINIONS AND MATING GEARS UP TO

34” (863.6MM) DIAMETER, 5” (127MM) FACE, WITH

1.08 DP (MODULE 23.5) CUTTING CAPABILITY

EQUIPMENT / FEATURES:

VARIABLE CUTTER SPEED ARRANGEMENT INCLUDING SET OF SPEED

CHANGE GEARS

ASSORTED RATIO-OF-ROLL, MODIFIED ROLL, AND INDEX CHANGE GEARS

W/TOOL & GEAR CABINET

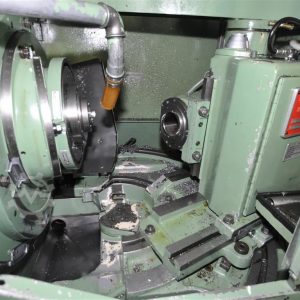

HYDRAULIC CHUCKING ATTACHMENT WITH DRAW-ROD & NUT

AUGER-TYPE CHIP CONVEYOR AND MAGNETIC CHIP SEPARATOR

CUTTER GUARD AND MANIFOLD FOR HIGH VELOCITY COOLANT

SECURITY COVER FOR SET-UP PANEL

STANDARD WORK SPINDLE BORE 6” X ¾” TAPER (#60)

MODIFIED ROLL MECHANISM, INCLUDING CHANGE GEARS FOR ONE PART

ROLL CENTERING

SLIDING BASE SET-IN MECHANISM, INCLUDING CONTROLS

CRADLE ROTATIONAL SET-OVER, INCLUDING CONTROLS

NO ROLL ARRANGEMENT FOR FORMATE AND/OR “DUAL-ROTATION” MACHINE

OPTIONS, INCLUDING CONTROLS

VARIABLE RATE OF ROLL ARRANGEMENT INCLUDING CONTROLS

DOUBLE ROLL ARRANGEMENT, INCLUDING CONTROLS

PLUNGE FEED MECHANISM

STOCK DIVIDING GAUGE

ECCENTRIC SET-OVER ARRANGEMENT INCLUDING CONTROLS

RELAY-LOGIC CONTROLS (IN PLACE OF STANDARD PROGRAMMABLE

CONTROLLER)

COMPLETE ELECTRICAL EQUIPMENT FOR 3-PHASE, 50 OR 60 HZ,

380-550 VOLT INSTALLATION, INCLUDING 110VAC OR 220VAC

CONTROL CIRCUIT, TEFC-AC MOTORS (NEMA T-FRAME OR T-FRAME

MODIFIED TO IEC DIMENSIONS), DC DRIVE AND CONTROL, AND

SINGLE-SPEED CUTTER MOTOR. ELECTRICS WILL COMPLY TO JIC

OR IEC TECHNICAL SPECIFICATIONS. DOCUMENTATION TO JIC STANDARDS.

MOST NUMBERS UP TO 120 CAN ALSO BE ACCOMMODATED BUT MAY REQUIRE SPECIAL CHANGE GEARS.

THIS RADIAL SETTING CAN BE INCREASED TO 18.5” (462.50MM) FOR SOME APPLICATIONS

MAXIMUM OFFSET APPLIES TO PINION AND GEARS UP TO 25” O.D. FOR 34” DIAMETER GEARS MAXIMUM OFFSET IS 0”