Description

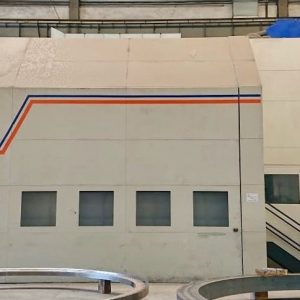

Gleason Phoenix 250HC CNC

Hypoid Bevel Spiral Gear Cutter

Face Milling:

Extreme Ratio 10:1

Full Depth (Max) 1.00″ (25.4mm)

Face Width (Max) 2.60″ (66mm)

Range of Tooth Numbers 5 to 200 Inclusive

Max pitch Diameter of Typical 35° Spiral Angle Gear Using Maximum Cutter Diameter -12″ Diameter Cutter

At The Following Ratios:

1:1 13.50″ (342.90mm)

2:1 16.00″ (406.40mm)

3:1 16.00″ (406.40mm)

Face Hobbing:

Extreme Ratio 10:1

Full Depth (Max) 0.60″ (15.24mm)

Face Width (Max) 2.00″ (50.8mm)

Range of Tooth Numbers 5 to 200 Inclusive

Max pitch Diameter of Typical 35° Spiral Angle Gear Using Maximum Cutter Diameter 350mm Diameter Cutter

At The Following Ratios:

1:1 10.56″ (268.22mm)

2:1 10.83″ (275.00mm)

3:1 10.83″ (275.00mm)

Cutter Diameters:

Face Milling:

Conventional Face Sharpened & RSR-C 2.75″ – 12″

HELIXACT & VERSACUT II 100mm – 320mm

Face Hobbing:

TRI-AC 102mm – 210mm

Machine Specs:

X-Horizontal Travel -4.50 to +7.00″ (-114mm to +178mm)

Y-Vertical Travel -7.00″ to +7.50″ (-178mm to +190mm)

Z-Sliding Base Travel -5.20″ to +19.70″ (-131mm to +500mm)

B-Root Angle -3° to 90°

Machine center to Work Spindle Face 6.50″ (165mm)

AXES SPEEDS

X-Horizontal 0 to 3.15″/Sec (0 to 80mm/Sec)

Y-Vertical 0 to 3.15″/Sec (0 to 80mm/Sec)

Z-Sliding Base 0 to 3.15″/Sec (0 to 80mm/Sec)

A-WorkSpindle 0 to 83 RPM 90 to 33 RPM metric)

B-Swinging Base 0 to 30 Deg/Sec

C-Cutter 0 to 400 RPM

Work Spindle Dimensions:

Diameter of Taper Hole – Large End 5-3/64″(50 Taper)

Taper Per Foot 21/32″

Depth of Taper 5.29″ (134.37mm)

Diameter of Hole Through Spindle 3.35″ (85.22mm)

1980s