Description

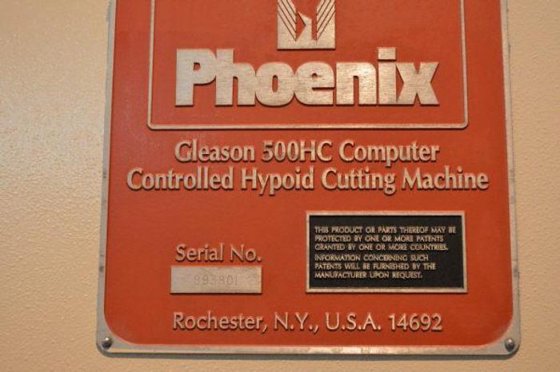

GLEASON PHOENIX 500HC – Year 1995

CNC SPIRAL BEVEL GEAR GENERATOR

GLEASON “PHOENIX” #500 HC CNC SPIRAL BEVEL GEAR GENERATOR

NEW 1995, SERIAL NO. 893801, MODEL NO. 500HC

SUITABLE FOR THE CUTTING OF SPIRAL BEVEL AND

HYPOID GEARS AND PINIONS UP TO 30” (762MM)

DIAMETER VIA “FACE-MILLING”, AND 22” (558.8MM)

VIA “FACE-HOBBING” METHOD UTILIZING THE TRI-AC

CUTTING SYSTEM

EQUIPMENT / FEATURES:

GE-FANUC 150M COMPUTER CONTROL WITH SPIRAL BEVEL GEAR

CUTTING SOFTWARE, CYCLE FAULT MONITORING, AND

MEMORY CAPACITY FOR 25 PARTS, WITH AUTOMATIC

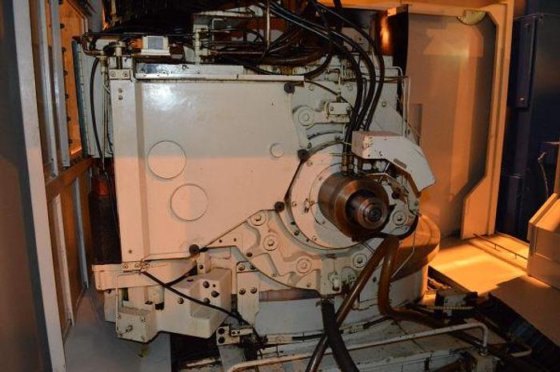

SETUP AND CONTROL OF SIX (6) AXES:

WORK SPINDLE ROTATIONAL AXIS (A)

HORIZONTAL LINEAR MOTION OF CUTTER AXIS (X)

SWINGING BASE OF WORK-SPINDLE AXIS (B)

VERTICAL LINEAR MOTION OF CUTTER AXIS (Y)

CUTTER SPINDLE ROTATIONAL AXIS (C)

SLIDING BASE LINEAR MOTION OF WORK-SPINDLE AXIS (Z)

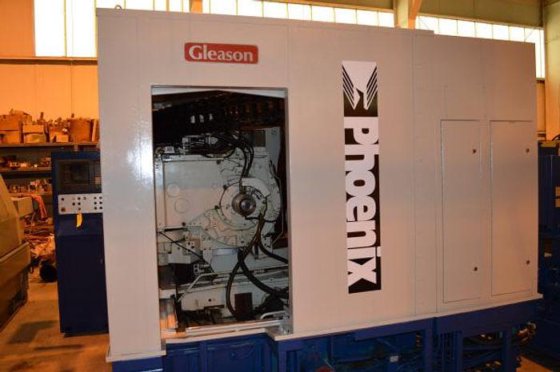

MACHINE FURNISHED WITH FREESTANDING, AIR CONDITIONED

ELECTRICAL ENCLOSURE. OPERATOR’S PENDANT LOCATED

AT FRONT OF MACHINE ADJACENT TO POWERED ACCESS DOOR.

THE SPIRAL BEVEL GEAR CUTTING SOFTWARE ON THE 500HC

MACHINE WOULD BE CAPABLE OF PERFORMING THE

FOLLOWING CUTTING PROCESSES:

FACE MILLING

COMPLETE GENERATED AND FORMATE GEARS

COMPLETE PINIONS OF GENERATED OR FORMATE PAIRS

ROUGH GENERATED OR FORMATE GEARS

ROUGH PINIONS OF GENERATED OR FORMATE PAIRS

ROUGH SLOT AND FINISH FIRST SIDE OF PINIONS USING ANY

SINGLE SIDE MODIFIED ROLL DEVELOPMENT METHOD

FINISH GENERATED OR FORMATE (NOT SINGLE CYCLE) GEARS

FINISH PINIONS USING AND SINGLE SIDE TILT OR MODIFIED

ROLL DEVELOPMENT METHOD

FACE HOBBING

COMPLETE GENERATED OR FORMATE GEARS

COMPLETE PINIONS OR GENERATED OR FORMATE PAIRS

EQUIPMENT

COMPLETE COOLANT PLANT, PUMP TANK & PIPING WITH

MAGNETIC CHIP CONVEYOR.

HYDRAULIC WORKPIECE CHUCK WITH DRAW-ROD.

WORK-SPINDLE BORE 8” (#80 TAPER) WITH OPTIONAL

ADAPTER TO 6” (#60 TAPER).

COMPLETE SET OF WORK SPINDLE RATIO GEARS.

TOTALLY ENCLOSED WORK-AREA GUARDING WITH POWERED

ACCESS DOOR.

WORK CHAMBER AND CONTROL BOX LIGHTING.

PRODUCTION AND SHARPEN-CUTTER COUNT DISPLAY

CLAMPING AND EJECTING EQUIPMENT FOR GLEASON

RSR-TYPE SPIRAL FACE MILLING CUTTERS 9” THROUGH

18” DIAMETER AND GLEASON TRI-AC SPIRAL FACE

HOBBING CUTTERS 176MM THROUGH 350MM DIAMETER.

MANUAL STOCK DIVIDER.

FORMATE SINGLE CYCLE GEAR FINISHING ARRANGEMENT.

SMOKE AND MIST COLLECTOR.

CHILLER UNIT FOR COOLANT SYSTEM.

WORK ARBOR CLAMP (FOR GEARS GREATER THAN 15”

IN DIAMETER).

ELECTRICAL EQUIPMENT FOR 380 VOLT, 50 HZ, OR

460 VOLT, 60 HZ, 3-PHASE INSTALLATION.

CONTROL CIRCUIT IS 110 VAC WITH 24 VDC INPUT AND

24 VAC OUTPUT

TRANSFORMER TO CONVERT LINE VOLTAGES OF 200 TO

240 VOLT, 50 OR 60 HZ TO 400 VOLT (FOR 50 HZ)

OR 460 VOLT (FOR 60 HZ).

FULL MACHINE DOCUMENTATION FOR THE MACHINE AND

CONTROLLER, REPLACEMENT PARTS LIST, HYDRAULIC

AND ELECTRICAL DIAGRAMS

PRICE: F.O.B. OUR WAREHOUSE