Description

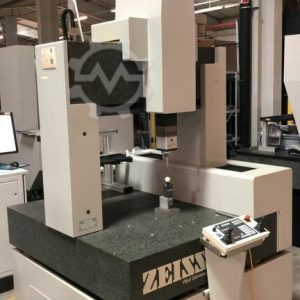

GOM ATOS ScanBox 5108 Optical 3D Coordinate Measuring Machine – Year 2020

Parts up to 800 mm in size are inspected with the 5108.

Due to the small dimensions of this box, manufacturers of

turbines, fans, blisks and cast housings often opt for this

model. With airfoil inspections, sharp radii can be recorded

in terms of their position and contour with a detailed image

resolution of more than 20 measuring points per mm.

GOM ATOS ScanBox 5108 Optical 3D Coordinate Measuring Machine

31.5″ Capacity FANUC M-20iA Robot (2) Cameras

GOM ATOS ScanBox

Optical 3D Coordinate Measuring Machine

For measuring room and production

Full-surface component analysis

GD&T, hole pattern and trimming

Optical 3D coordinate measuring machines are replacing tactile measuring systems and gages in many areas of industry. They capture more detailed and more easily interpretable quality information of an object with significantly shorter measuring times.

Whereas mechanical measuring systems capture data in a point-based or linear manner, optical measuring systems return full-field data about deviations between the actual 3D coordinates and the CAD data. As this measuring data contains all the object information, in addition to the surface deviations from the CAD, the software also automatically derives detailed information such as GD&T, trimming or hole positions.

The accuracy of optical measuring machines is not due to expensive and high-maintenance precision mechanics, but is rather

based on state-of-the-art optoelectronics, precise image processing and mathematic algorithms. Few precision standards and

automated calibration that can be performed by the customer ensure the accuracy of the machine. This also means no loss of

accuracy due to wear under harsh conditions. As with the tactile machines, measuring uncertainty is certified with the help of

ball bars or step gauges.

Over 14,000 GOM measuring systems worldwide ensure the dimensional quality of automotive, sheet-metal, cast and injection molded products as well as turbine blades and wheels. In most cases, the detailed analyses are not used for a simple

“OK”/“not OK” evaluation, but rather form the basis for the optimization of production and machine parameters as part of a

value-added measuring procedure.

Measuring Room

Typically, a wide range of different parts are handled in the

measuring room. The measurement engineer creates both

the measuring programs and the evaluation templates, together with the measuring reports, offline on the computer

in a CAD-like environment. Special Auto Teaching functions

speed up programming and ensure process reliability. After

the actual measurement, the previously created evaluation

templates are filled with real measuring data, deviations

from the nominal value are calculated and the reports are

automatically generated.

Production

Robustness, measuring speed and compensation for

temperature fluctuations are convincing factors in production, enabling traceable results to be captured even under

harsh conditions. As the machines can be operated close

to production, the work-intensive transportation of components can be omitted. The operator works on the system in

an encapsulated mode (Kiosk Interface), which means that

precise measurements can be performed and measuring

reports can be created without any knowledge of measuring

technology.

GOM Sensors

High Tech in Robust Machines

ATOS 3D Sensors

The core of all the ATOS ScanBox systems is the ATOS 3D scanner, which GOM has offered since 1995. The ATOS sensor is currently available in three different model ranges for diverse applications.

High image resolution and measuring speed – The ATOS sensors return full-field distributed 3D coordinates for each individual measurement. Up to 16 million independent measuring points are captured within 1 to 2 seconds. The measuring data is characterized by very high detailed reproduction, thus also enabling very small component features to be measured.

ATOS Plus – In GOM measuring machines, the ATOS sensors are typically operated together with the Plus Box. The latter is a photogrammetric add-on sensor which can be directly attached to the ATOS system. This enables, with a total measuring volume of 500 x 500 x 500 mm³ to 6000 x 3000 x 3000 mm³, reference point markers with deviations from 3 µm to 30 µm

to be measured fully automatically. These reference points then form the basis for the overall accuracy.

If the ATOS sensor detects one of these reference points in a number of individual measurements, it is transformed into the 3D volume which spans these points. In this way, the measuring accuracy of the overarching photogrammetric measurement is achieved.

Triple Scan Principle – Precise fringe patterns are projected onto the surface of the object and are recorded by

two cameras, based on the stereo camera principle.

As the beam paths of both cameras and the projector

are calibrated in advance, 3D surface points from three

different ray intersections can be calculated: Visual

beam camera/camera, visual beam camera on left/projected beam projector and camera on right/projected beam projector. This automatic principle offers advantages for measuring reflective surfaces and objects with indentations. If a ray intersection is not possible for a ray combination due to reflection or indentation, the other two are used. The result is complete measuring point

distributions without holes or erratic points.

Blue Light Technology – GOM projection technology works with narrow-band blue light, which means that interfering ambient light during image acquisition can be filtered out. The light sources are so powerful that short measuring times can be achieved even on uncooperative surfaces. In addition, they have a life expectancy of well over 10,000 hours.

Self-calibration – The ATOS sensors are fully self-calibrating. The ATOS ScanBox contains a certified calibration panel and two certified scale bars in the vicinity of the object. Prior to and after the measurements, these normals are recorded from different directions. On the basis of the acquired images and the calibration data of the normals, self-calibration of the sensors is performed without any operator intervention, by the definition of many thousands of imaging and geometry parameters. As the expansion coefficients of the normals are known, the ATOS ScanBox can be operated in a wide ambient temperature range as automatic self-calibration is carried out at the appropriate temperature.