Description

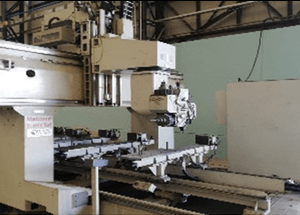

Hartford HEP-3150 – Year 2010

CNC Double Column Vertical Machining Center 3.25 Meters

| Axis X | 3250 mm |

| Axis Y | 1500 mm |

| Axis Z | 780 mm |

| Rotary table (4th axis) | no |

| Type of CNC | Fanuc |

| Table length | 3000 mm |

| Table width | 1400 mm |

| Max. part weight | 7000 kg |

| Spindle taper | BT50 |

| Hartford HEP-3150 | CNC Double Column Vertical Machining Center |

| Worked hours | 43779 hours |

Hartford HEP-3150 Double Column Vertical Machining Center

Machine is in good working condition

Working hour : (July 2023)

Fanuc control unit

X : 3250 mm

Y: 1500 mm

Z : 780 mm

Manufacturer Catalogue Information about

Hartford HEP-3150 CNC Double Column Vertical Machining Center :

WORKING AREA

| Working Surface Size (Length x Width) | mm | 3000X1400 |

| Max. Workpiece Weight | kg | 7000 |

| Height Between Table and Spindle | mm | 160+780=940 |

| Distance From Spindle Center to Column | mm | 430 |

AXES

| Guideway Type | LINEER | |

| X-axis Travel | mm | 3250 |

| Y-axis Travel | mm | 1500 |

| Z-axis Travel | mm | 780 |

| Positioning Accuracy (JIS B6330) | mm | 0.010 |

| Repeatability Accuracy (JIS B6330) | mm | 0.003 |

| Positioning Accuracy (VDI 3441, 5 times) | mm | 0.015 |

| Repeatability Accurac (VDI 3441, 5 times) | mm | 0.014 |

SPINDLE

| Spindle Speed (Gear) | devir / dk | 6000(8000) |

| Spindle Speed (Direct Drive) | devir / dk | 10000(12000) |

FEED RATE

| Cutting Feed Rate (X, Y, Z) | mm / dk | 1~8000 |

| Rapid traverse (X, Y, Z) | mm / dk | 15000/15000/15000 |

AUTOMATIC TOOL CHANGER

| Tool Number | adet | 20 |

| Max. Tool Weight | kg | 15 |

| Max. Tool Size (Diameter and Length) | mm | 125 x 300 |

| Pull stud bolt | P50T–1 |

CONTROL UNIT

| MITSUBISHI | M830S,M830W | |

| FANUC | 0İMF,31İMB | |

| HEIDENHAIN | İTNC530 |

OTHER

| Required air pressure | kg / cm2 | 6,5 |

| Electric Power Consumption | KVA | 50 |

| Machine Weight | kg | 22950 |

| Machine Floor Space | mm | 10200 x 5640 |

STANDARD ACCESSORY

Semi-enclosed Splash Guard

Spindle air curtain

Coolant Tank

Pre-load on 3 axes

Z axis counter balance

Table side air blast M50 control

Spray around spindle

Tool package

Hartford manual x 1

RS-232

Operator panel,rotary type

Automatic power off

Lubriction syste

Fluorescent lamp x 1

Foundation bolt,General

OPTIONAL ACCESSORIES

Full-enclosed splash guard & top cover

NC rotary table

Front mounted screw type chip conveyor

Link type chip conveyor

Coolant flushing device

Coolant through spindle

Wash down hose

Air gun

Spindle oil cooler

Automatic door system operating door

Auto tool length measurement

Auto workpiece measurement

Coolant-loop linear scale positioning system

Ladder of maintenance

Fluorecent Lamp x 2

Three-Steps treadle

L1500 x W810 x H852mm