Description

Hymson HF3015B Fiber Laser Machine

CNC Fiber Laser Cutting Machine 3000W

Brand New

Make: Hymson

Model: HF3015B- 3000M

Working Range: 3000MM X 1500MM

Max Table Load: 1763.7 Lbs

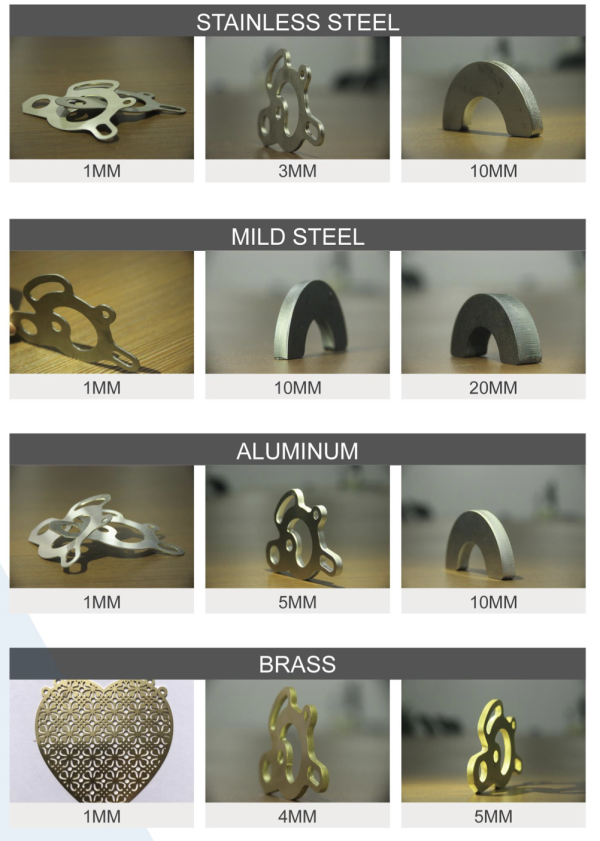

Max Cutting Thickness (Stainless Steel): 10MM

Max Cutting Thickness (Aluminum): 8MM

Max Cutting Thickness (Brass): 6MM

Max Cutting Thickness (Carbon Steel): 22MM

Z-Axis Track: 240MM

X/Y Axis Positioning Accuracy: ±0.03MM/M

X/Y Axis Repetition Positioning Accuracy: ±0.02MM

X/Y Axis Max Positioning Speed: 140M/Min

X/Y Axis Max Acceleration: 1.0g

Z-Axis Max Positioning Speed: 30M/ Min

Z-Axis Max Acceleration: 1.0g

Ip Degree: IP54

Asset Brand New

Please Call For Additional Information

INCLUDES:

Shipping, insurance, local transportation and tariff

Manufacturer Catalogue Information about

Hymson HF3015B Fiber Laser Machine :

FEATURE

The HF · B series laser intelligent cutting equipment is the ideal economical machine for high- quality sheet metal laser cutting.

Low operation and maintenance cost, high-quality laser cutting can be easily achieved. Varies of materials with different thickness can be handle with barely help from man.

Industrial-grade high-strength honeycomb structure machine tools ensure long-term stable operation of equipment. Enclosed protective cover and intelligent exhaust system provide extremely high standard laser and production safety protection.

FIBER LASER RESONATOR

Light is already coupled into a flexible fiber: The fact that the light is already in a fiber allows it to be easily delivered to a movable focusing element. This is important for laser cutting, welding, and folding of metals and polymers

High output power: Fiber lasers can have active regions several kilometers long, and so can provide very high optical gain. They can support kilowatt levels of continuous output power because of the fiber’s high surface area to volume ratio, which allows efficient cooling

High optical quality: The fiber’s waveguiding properties reduce or eliminate thermal distortion of the optical path, typically producing a non-diffraction, high-quality optical beam

Compact size: Fiber lasers are compact compared to rod or gas lasers of comparable power, because the fiber can be bent and coiled to save space.

Reliability: Fiber lasers exhibit a great stability under the high temperature and vibrational environment. Also, it has the features of extended lifetime, and maintenance-free turnkey operation

High peak power and nanosecond pulses enable effective marking and engraving.

Fiberlasersarenowbeingusedtomakehigh-performancesurface-acousticwave(SAW)devices.

These lasers raise throughput and lower cost of ownership in comparison to older solid-state laser technology

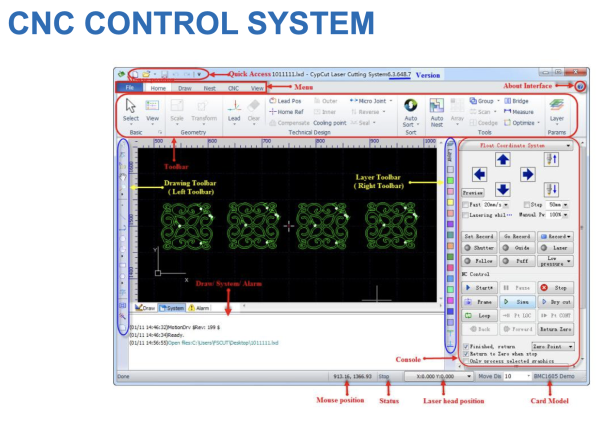

CNC CONTROL

CYPCUT CONTROL PLATFORM

The equipment uses FSCUT laser cutting control system, equipped with a large screen display, and it’s a professional laser cutting system. Based on Windows operation system, FSCUT integrates a lot of laser cutting modules with special functions. Equipped with a wireless keyboard and mouse, the operation is simple and easy

We provide full-featured CypCut cutting software. This software is feature-rich, highly simplifies and optimizes the cutting process, significantly improving operator efficiency and productivity

The operator sets up before the start of processing and does not need to stop the material handling during processing

CypCut provides common drawing functions, which can be easily used from the left drawing toolbar. Most of these drawing functions are similar to AutoCAD, and they are also very intuitive to use. The software has a variety of user-friendly graphics operating functions, simple and quick to get started

CypCut software supports graphic data formats such as AI, DXF, PLT, Gerber, and LXD, accepts international standard G codes generated by Master Cam, Type3, and other software, and automatically optimizes when external files such as DXF are opened/imported, saving time and efficiency

In order to obtain high-quality acute and right angles, the software is equipped with real-time frequency and power curves, and the power of the laser radiation is automatically adjusted according to the speed of movement of the cutting head. When the cutting head is at zero speed (at the time when the corner is stopped), the output radiant power is equal to the minimum power set in the setting to prevent burnout of the corners

The engraving and cutting modes are set individually by the operator before the cutting starts. The operator can reconfigure the machine and enter new settings without having to stop the material handling process. Switching between modes occurs automatically, which increases the

productivity of the cutting complex

CypCut software reads the special material library, selects the corresponding material library

parameters according to different materials, and modifies the storage operation

CypCut provides 16 layers, and each layer can be individually set including cutting speed, laser power, air pressure, cutting height and other process parameters. The color of each layer is

unique, which is convenient for browsing and configuring cutting graphics parameters

The simplicity of the CypCut software allows you to shorten the time the mid-level expert learns the basic work of the machine. The work cost of mid-level experts will be much lower than highly intelligent experts, which will have a positive impact on production costs. CypCut software also offers free upgrades. The software also allows monitoring and control of the installation system:

tracking systems, cooling systems, lasers, and viewing node logs

The BCS100 self-contained capacitor height adjuster (abbreviated as BCS100) adopts a closed-

loop control method to control the laser-cutting capacitor follower and provides a unique Ethernet communication (TCP/IP protocol) interface. It is easy to implement high-speed automatic tracking and sharing with CypCut software. Section perforation, progressive perforation, edge-seeking cutting, frog-leaping lifting, cutting head elevation setting, flight optical path compensation, etc. The BCS100 adopts a double-closed-loop algorithm with speed and position. Its performance, such as speed and accuracy, is significantly better than similar products at domestic and abroad market

Leapfrog: When the material burns, the optical head rises to the jump height set by the operator. As the head is raised, the metal melt does not fall on the nozzle part, and cannot be derived or the whole optical head fails. Cut further from the set distance

Uninterrupted Cutting: This method can significantly reduce the processing time of the sheet because it does not cut every detail individually, but instead cuts all the contours into a straight line. The high-speed optical head delivers the entire sheet line by line, cutting out the contours of the corresponding segments.

CUTTING DATA BASE LIBARAY

The laser system features an integrated cutting data base with parameters for many common material and different material-cut conditions. The machine operator can make modifications to the cutting data base at the control panel. The cutting data base management software can list all of the available material files or can requested to display only those files that meet certain criteria. For example, the system can display only those materials of a particular type or thickness that fit in a process group. Using the cutting data base management system, the operator can select closest existing cutting data file as a starting point for next cutting applications, different applications (precision, standard, high speed, etching, etc.)

MACHINE BASE

Utilize state-of-the-art welding technology to form the machine tool base

Heat treatment to strengthen the intensity and stiffness of base

First step processing and second time mechanical stress relief, after these steps the machine

base proceed with semi and final processing procedures.

Hymson patented machine base design, its structure matches industrial machine tool standard

with high accuracy and rigidity, and machine mechanical stress has been completely removed

during the process of welding and machining

Machine frame has been designed and welded in honeycomb structure, which is effectively

spread the thrusting force produced by motion of electric motor to every part of the machine and thus guarantees the machine runs extremely stable