Description

GLEASON Phoenix 175HC

Gleason Phoenix 175HC gear generator

Model No. 175HC GLEASON Phoenix “CNC” Spiral Bevel Gear Generator,

suitable for the cutting of spiral bevel and hypoid gears and pinions up to 8.5”

(216mm) diameter via “face-milling” and 7.5” (190mm) via “face-hobbing” method.

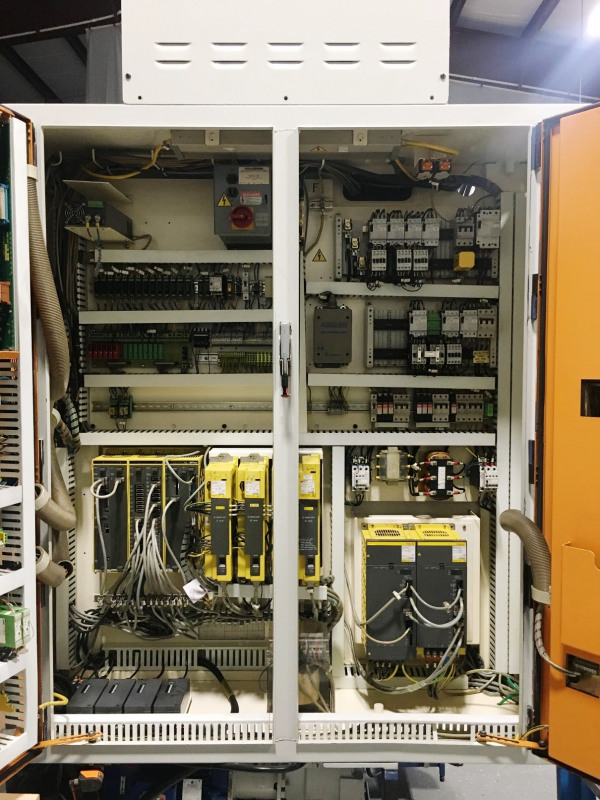

Machine furnished with machine mounted, air-conditioned, electrical enclosure,

operator’s controls located at front of machine, adjacent to powered access door.

FANUC Model 150MB computer control with spiral bevel gear cutting software and

automatic set-up, with 10.4” LCD flat color display.

Work Spindle (A) Swinging Base (B) Cutter Spindle (C)

Horizontal (X) Vertical (Y) Sliding Base (Z)

Summary storage capacity for 100 parts.

Security key for control of set-up.

Cycle fault monitoring

Production and sharpen – cutter count display

Hydraulic work-piece chuck (w/draw-rod & nut).

Work spindle bore (3-29/32: (#39 taper).

Work-head ratio gears for 5:1 (others ratios available upon request)

FORMATE single-cycle gear finishing arrangement

Totally enclosed work area guarding with powered access door.

Work chamber lighting

Foot switch for hydraulic chucking of work-piece

Power forced lubrication system to all working elements

Self contained coolant system (pump tank & piping)

Magnetic chip separator (24”chip exit height).

Electrical equipment for 380 volt, 50 Hz, or 460 volt, 60 Hz, 3-phase

installation. Control circuit is 115 VAC with 24 VDC input/output.

Electrics to comply with PHOENIX NFPA 79-1987 specifications

Full machine documentation, wiring & hydraulic diagrams

EXTRA: For professional export packing/preserving for sea-worthy transport, into 40-Ft. “HQ” ocean cargo container

EXTRA: “Refurbished” Koolant Koolers chiller unit