Italmac ONIX 3300 3AX – Year 2020

Contact us for price

Description

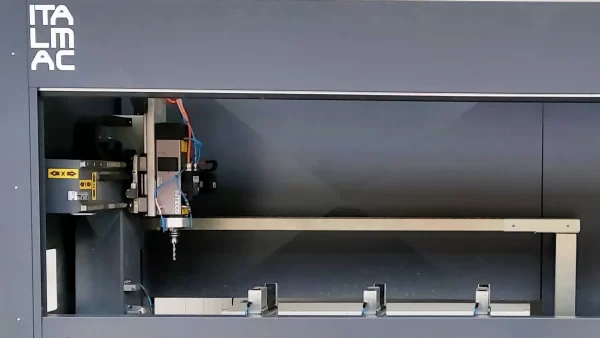

Italmac ONIX 3300 3AX – Year 2020

CNC aluminium profile machining centre

Technical parameters of the aluminium profile machining centre ITALMAC ONIX 3300 3AX

maximum workpiece length: 3300 mm

maximum workpiece dimensions (machining 1-2 surfaces, angle head): 3300 x 160 x 210 mm

maximum workpiece dimensions (machining 3 surfaces, angle head): 3300 x 120 x 180 mm

feed rates in the X/Y/Z axis: 3450/660/265 mm

rapid feed rate in the X/Y/Z axis: 40/40/15 m/min

acceleration in the X/Y/Z axis: 1.5/1.5/2 m/sec2

electro-spindle speed range: 0-18000 rpm

electro-spindle power: 4 kW

tool head capacity: 8 pcs.

working hours: approx. 600 h

clamping force: 130 kg/clamp

accuracy: 0.1 mm

total power requirement: 8 kW

working pressure: 7 bar

power supply: 400 V; 50 Hz

overall dimensions (L x W x H): 4600 x 1675 x 2260 mm

total weight of ONIX 3300 3AX machine: 1800 kg

Equipment of the aluminium profile machining centre

CNC controller

CAD/CAM software: ITALSOFT VISUAL 3D

electro-spindle: HSD

angle head

brushless axis servomotors

positioning clamps (4 pcs)

toolholder: ISO 30

automatic tool loading system

sound-proofed cabin

impulse oil lubrication system

control panel (keyboard, mouse, 17″ monitor, 500 GB hard drive)

USB port (2 pcs)

ITALMAC ONIX 3300 3AX aluminium profile machining centre was built in Italy in 2020. The machining centre is used in the process of drilling and milling profiles made of light steel alloys and aluminium profiles, such as window profiles or door frames. A high-performance electro-spindle with a power of 4 kW, together with three interpolated X,Y,Z axes equipped with top quality brushless servomotors, guarantee the highest precision and quality in the machining of a workpiece having a maximum length of 3300 mm.

The aluminium milling machine is equipped with a high-quality sound-proofed cabin, preventing dust from settling on the machine’s mechanisms and significantly reducing noise levels during the machining process. The machine also features, amongst others, an angle head, a tool magazine with a capacity of 8 tools, a modern CNC controller with easy-to-use CAD/CAM software ITALSOFT VISUAL 3D and four positioning clamps. The condition of the CNC machining centre is very good – the milling machine has been in operation for just 600 hours. The total weight of the machine is 1800 kg.