Description

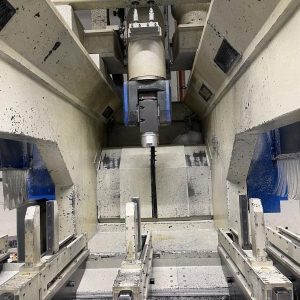

ITALMAC PEGASO – Year 2021

5 Axis working center PEGASO

High-performance profile machining center with a main spindle of up to 16 kW and workpiece clamping with high clamping force to machine profiles up to 640 mm high. The 15-fold tool changer directly on the axis enables efficient work regardless of the profile length.

Incl. the leading high performance German CAM system Camprox.

Model: 4.0

Dimensions: 6800 × 3100 × 2500 mm

Weight: 3200 kg

Electric spindle power: 10 kW

No. of reference points: 2 pneumatic

No. of standard clamps: 6 automatic

Tool storage: Tool storage with 15 positions attached to

the trolley (expandable to 30)

Rotation of axis A: From -120° to +120°

Rotation of axis C: From -240° to +240°

x-axis: 4470 mm

y-axis: 1325 mm

z-axis: 600 mm

Axis speed: X 100 m/min; Y 60 m/min; Z 30 m/min

5 Axis CNC Machining Centre

This machine is a light, 5 axis machining centre with a mobile column. Designed for

milling, drilling, threading and cutting large size aluminium bars, irons and profiles in light

alloys & steel, it is the most popular machine in the light industry.

The 10kW powered electric spindle in S1, with tools attachment HSK-63F, guarantees

good results in even heavy machining. The automatic tools warehouse, on the mobile

head, can host 16 tools and can be expanded up to 30 places.

There is a 500mm tool blade compartment with specific a warehouse separated from the

tools warehouse. The machine can be used in pendulum mode (in 7m and 9m versions),

maximising production and executing the part exchange at the same time. This therefore

reduces machine downtime to a minimum and is highly efficient with independent

automated vice positioning compared to the standard automatic positioning through a

gantry.

The machining centre also has a 90o cutting unit with a 450mm saw blade, for large sized

profiles. Pegaso’s column feature not only protects the operator but also allows maximum

visibility of production and reduces the acoustic environmental impact.

A version is available with a booth.