Description

JJ SMITH MOBI-ONE – Year 2015

AUTOMATIC FRAMING AND NAILING TABLE

BRAND JJ SMITH type “MOBI-ONE – 8/3.5″

Year: 2015

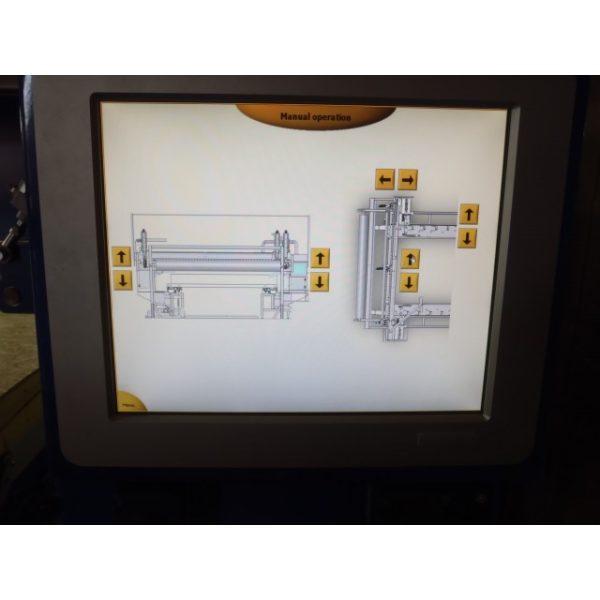

CNC: Double control panel with 17’ color touch screens

Display of the plan of the panels, the positioning dimensions and Zoom function Data recovery drawing software by interface

TABLES:

Assembly tables with a fixed part and a movable part, each with useful support surface of 400 mm width and 850 mm working height

The moving part is equipped with gear transmissions ensuring the synchronization of the movement over the entire length of the table

The rails with racks are fixed to the ground by dowels and adjustment screws, ensuring perfect straightness and rigidity to the whole

Motorized mobile table in movement by brake motor with adjustable pressure, for clamping frames.

STOPS:

At the front, 2 framing stops, and 2 clamps of the first crosspiece, are pneumatically liftable and retractable for the exit of the panel. Control at the console by solenoid valves.

On each side, along the fixed and mobile tables, a row of independent lateral stops, each of which is pneumatically retractable to automatically retract when the horizontal nailers pass.

These stops with a height of 85 mm (for mini panels h=90mm) prevent the top and bottom rails from “opening” upwards and keep them perfectly vertical and square when tightening the frame.

When moving the MOBI-ONE gantry, the mobile table releases its pressure on the frame, allowing the introduction of a new crosspiece or a sub-assembly, then tightens the assembly again before the nailing operation .

GANTRY:

Gantry with 1 motorized travel nailing trolley.

Digital positioning in automatic mode

Programming of nailing centers

Ball bearing slides supporting the nailing trolley

Carriage movement by rack and servomotor

Support for the industrial type nailer(s) (3 max)

Option for on-board router, with CNC control

NAILING:

Nailing or stapling depending on the type of operations performed.

The mobile top carriage supports:

– 1 digitized nailer for lathing (ITW ref CW650)

– 1 digitized stapler with charger (ITW Paslode ref S540) for OSB

Motorized movement by industrial-type servomotor and automatic nailing, with nailing centers programmed on CAD.

Manual adjustment by wheel of the height of the nailer supports on vernier.

Pneumatic descent independent of each nailing unit, allowing adaptation to differences in frame thickness without prior adjustment (eg: 145 to 120 mm)

Roller guide on top of bracing panel

Device to avoid nailing at the level of the openings (fiber optics)

Lateral nailing: 2 side boxes, integrating the side nailers on the sides of the gantry, and moving on rails, the whole being pneumatically retractable.

Servo-cylinders, incorporated in these boxes, with movements on THK slides, control the nailers in height, and are configured to receive nailers with extended magazine and pneumatic firing remote control.

Automatic positioning and number of nails according to automatic software programming

2 ITW PASLODE side nailers Included capacity 130 mm.

RIPPER: The top carriage carries a ripper aggregate on the front.

Motorized movement by industrial-type servomotor and automatic machining, with movements programmed on CAD in X and Y.

Electronic speed variator with console programming.

Industrial electro-spindle

Programmed automatic start

Pneumatic lowering of the ripping aggregate allowing adaptation to all frame thicknesses without prior adjustment (e.g.: 145 to 240 mm) Roller guide on the top of the bracing panel

Interpolation of the axes allowing displacements on angles as well as in curve according to defined radius

Dust extractor mounted on the upright of the gantry, with flexible pipes for connection to the suction nozzle.

Automatic suction start with the routing function.

Suction capture device around the wick

EVACUATION:

2 lines of running rollers, free, incorporated along the entire length of the tables. They can be lifted pneumatically, at the end of nailing, facilitating the exit of the panel towards an exit table (manual push).

Lift control at the desk by solenoid valve.

OPERATION: Principle of “Functions”:

– 1st function: Frame assembly with automated side nailing

Gantry put in parking position at the end of the frame

Manual installation of OSB and manual pre-nailing

Maintaining the framing and squareness during this operation

– 2nd function: Fully automatic bracing nailing

in CNC mode with top nailers

Programmed nailing centers

Maintaining the framing and squareness during this operation

– 3rd function: Routing openings and outer edges

with PN descent router and CNC controlled

and on-board suction device.

– 4th function: Semi-automatic nailing of cleats

Positioning of the automatic gantry above the

sleepers. Guidance system. On-board storage rack

Maintaining the framing and squareness during this operation

On-screen display of the number of cleats to be loaded

C/ Technical characteristics of the MOBI-ONE:

Minimum panel width 1300 mm

Stroke of the moving part 2,200 mm

i.e. maximum width of the panels 3,500 mm

Maximum panel length 8,000 mm

Minimum panel length 500 mm

Maximum frame thickness 500 mm

Important: The fixed table (low rail) / Point 0-0 located on the right hand.

D/ Technical characteristics of the MOBI-ONE (continued):

General electrical cabinet integrated in the gantry.

2 consoles with color screens with touch control, one inside on a bracket for framing and one outside, touch screen PC under Windows environment.

Ergonomic control interface with menu access and visualization of the wall panel under construction. Follow-up of the work by color codes on the uprights.

CE safety specifications

Light curtains on the gantry at the operator station

Automatic stop device in the event of an obstacle on the fixed upright of the gantry

2 light curtains on the mobile side

E/ Complete combination equipped with:

– Device for automatic nailing of cleats with CNC control

– Support second nailer holder on mobile trolley

– Power supply and stem on the bridge for flying nailer (not supplied)

– Digitalized router with electronic variator and suction

– Pneumatic intermediate support device for sprockets

– Alignment lasers

– Second interior screen with touch control

Weight 4500 kg

Manufacturer Catalogue Information about JJ SMITH MOBI-ONE :

MBA – Mobi One Combined Timber Frame Assembly Station For Walls

Leading manufacturer of equipment for the timber & steel offsite manufacturing sectors

Complete integration with design packages

Space saving

One man operation

About this Product

A self-assembly heavy duty modular timber frame table suitable for framing and boarding of panels. The modular 2m or 3m x 1m tables can be assembled in various configurations, to suit either wall panels or floor cassettes.

SPECIFICATION

4 off 2m / 3m x 1m Modular tables suitable for frames up to 4m / 6m x 2.8m

PLY top with channel for fitting (optional) pop up rollers

Complete with:

1 fixed infill for spacing the table to 2.8m capacity

1 sliding infill for supporting subcomponents inside the panel.

9m of fixed fence (6m length x 3m width)

2 pneumatic connections for nail guns

Working Height 700 – 850mm

OPTIONS

Additional modular table (2m x 1m)

Additional modular table (3m x 1m)

Fixed infill (800mm)

Fixed infill (1000mm)

Movable infill (800mm)

Movable infill (1000mm)

Extra per m of infill channel

Extra per m of fixed fence

Pop up rollers per meter of additional modular table

Removable pins and cams (each)