Description

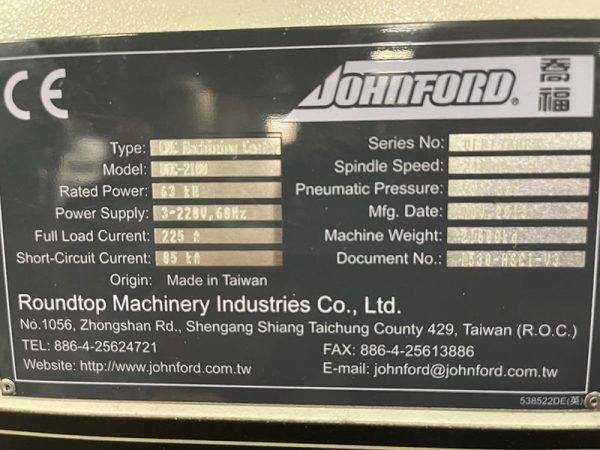

JOHNFORD DMC-2100HN HI-NET – Year 2013

| X | 2,049.8 mm |

| Y | 1,295.4 mm |

| Z | 800.1 mm |

| Power | 23.1 kW |

| RPM | 24,000 RPM |

| Table-W | 850.9 mm |

| Table-L | 1,300.5 mm |

| # ATC | 40 |

| Taper | HSK-63 |

| Dimensions | 236″ x 130″ x 150″ |

| Weight | 52000 |

| Control | CNC (Heidenhain i530-TNC) |

JOHNFORD DMC-2100HN HI-NET – Year 2013

EQUIPPED WITH

Weiss Integral Spindle, 24,000 RPM, 40 Tool ATC, HSK-63, Heidenhain Scales on X, Y, Z-Axis, Air/Oil Mist for Spindle Lubrication/Cooling, Heidenhain i530-TNC Control

(X) Axis 80.7″ Cross Travel

(Y) Axis 51” Vertical Travel

(Z) Axis 31.5″Table to Spindle 5.9″ min/37.4″

max Distance Between Columns 51.2″ Table

Table Working Surface 86.6″ x 43.3″

Maximum Workload on Table 13,200 LBS.

Table Surface Ground / T-slotted No. of T-slots x Width 7 x 22mmSpindle (Weiss)

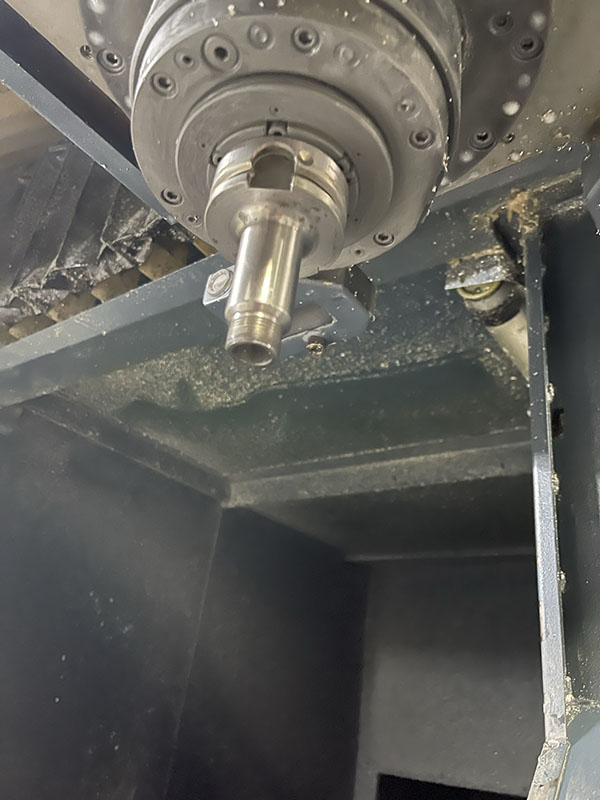

Spindle Motor 31 HP Integral

Spindle Torque 53 ft/lbs at 3000 RPM

Spindle Taper HSK-63A

Spindle Drive System Integral Motor

Spindle Speed 0-24000 (air / oil mist lubrication)

Automatic Tool Changer (arm type) Number of Tools 40 tools

Tool Selection Bi-directional-random

Tool Change Time 6 sec tool to tool

Maximum Tool Diameter 3″ with adjacent tools, 4” without

Maximum Tool Weight 22 LBS

Tool Type HSK-63A

Maximum Tool Length 12.6″

Ballscrews and Axis Motors X-Y-Z

Ballscrew Diameter 2.5” X, 2.5” Y, 1.97”Z x 10 pitch

Ballscrew Type Class 3 double nut pre-loaded

Ballscrew Mounting Type Pre-tensioned X-Y-Z Servo Motor HP 9.0 – 9.0 – 5.2HP

Servo Motor Mounting Direct coupled XY, 3:5 Z Feeds Rapid Traverse Rate X,Y,Z 590, 590, 472 IPM Cutting Feed Rate 0.01 – 394 IPM Positioning Accuracy +/- .0003″ full stroke Repeatability +/- .0002″ General Coolant Tank Capacity 120 gallons

Machine Weight (base machine only) 52,000 LBS

Floor Space 236″ X 130″ x 150″

Machine Power Source 208/220 Volts, 3 Phase 125 Amps** Air Source 90 PSI

Standard Machine Accessories

Flood Coolant System with programmable air blast Air blast for spindle Auto Lubrication with Alarm Automated chip removal system with chip conveyors Halogen work lamp 2 speed geared head with spindle / headstock cooler Remote Handwheel Heat exchangers for control cabinets Hydraulic counterbalance for headstock Rigid Tapping.

The Hi-Net DMC-2100HN is a high performance double column machining center designed for high speed machining of complex 3-D shapes. The Hi-Net concept was developed to meet the needs of high speed, net shape machining in mold, die, and aerospace machining. Simply put, the machine is built to machine shapes in a variety of materials at high feedrates and with a high degree of accuracy. To accomplish this task, it takes a very well built machine.

We start with a cast iron machine frame that weighs in at 26,400 lbs. The machine design features a moving table and fixed column for maximum rigidity. A rugged 90 degree bridge with offset Y axis ways and a wide saddle keeps the spindle center line extremely close to the bridge for rigidity. The columns and bridge are a one piece casting for the best rigidity.

The massive Z axis head and Y axis saddle feature square box ways coated with Turcite and have been designed with diagonally arranged ribs that will help reduce the amount of distortion that is caused by years of continued service. The X axis table traverse is accomplished via heavy duty Schnerberger roller linear ways for accurate positioning of heavy work pieces.

Accurate positioning is carried out by large diameter, pre-tensioned ballscrews and powerful servo motors. The servo motors are directly coupled to the ballscrews via rigid couplings. Weiss integral spindles, made in Germany, are standard equipment. Both spindle features ceramic bearings with Vogel air/oil mist lubrication for best life.

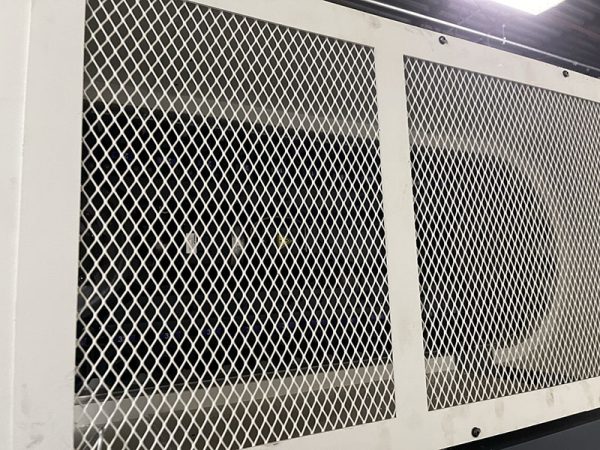

An impressive list of standard features includes a heavy duty 40 tool (HSK- 63A) that is mounted to the machine column for easy maintenance, a chip removal system consisting of 2 screw type conveyors on each side of table that discharge into a caterpillar type conveyor at the end of the machine, a high volume coolant system, and a full machine enclosure (including the top) to contain chips and coolant.

The Heidenhain i530-TNC Control is loaded with high speed machining options as standard for high speed, high accuracy machining. This machine is intended for high speed Near Net machining of complex 3D shapes and molds.