Description

Kellenberger 600 U – 125 – Year 1994

High Precision Swiss Cylindrical OD/ID Grinder

General Specifications:

Height of Centers: 9.8″

Swing with Factory Riser Blocks: 19-5/8″

Distance Between Centers: 23-3/8″

w/ Tailstock: 29-1/2″

Table

Longitudinal Table Travel: 35-7/16″

-Per Turn of Handwheel:

-Coarse: 25/32″

-Fine: 3/32″

Longitudinal Table Speed: 0.6 – 240 IPM

Table Swivels: +11/11 Degrees

Reversing Dwell: 0-5 Seconds

Grinding Wheel

Travel with Handwheel (Coarse/Fine): 8-21/32″

Infeed Per Rev. of Handwheel (Coarse/Fine): 0.3″ / .04″

1 Graduation of Feed Scale: 0.0002″

Division of Micro-Correction: 0.00004″

Automatic Hydraulic Infeed: 0.037″

Auto Infeed per Table Reversal: 0.00004″ – 1.18″

Infeed for Plunge Grinding: 0.00001″ – 0.0001″

Plunge Grinding: Infeed Speed: 10 – 1,000 uIN/Sec

Micrometer Stop, 1 Graduation: 0.00004″

Universal Grinding Spindle Head:

Traverse Movement of Wheel Slide: 11-1/4″

Hydraulic Rapid Wheel Slide Advanced/Retraction

– Stroke: 1-9/16″

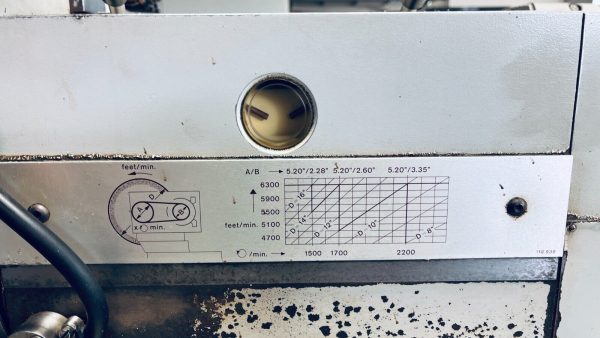

– Grinding Wheel Speeds (4): 1500, 1700, 2200 RPM

Grinding Wheel for Cylindircal Grinding: 16″ x 2″ x 5″

Grinding Wheel (Face Grinding): 12″ x 1-1/2″ x 5″ or 10″ x 3/4″ x 3″

Swivel of Grinding Head w/ Locking Every 90 Degrees: +5 / -195 Degrees

Workhead

Infinitely Variable Spindle Speeds: 600 RPM

Workhead Swivels: +120 / -30 Degrees

Inside Taper of Work Spindle: #5MT

Tailstock

Internal Taper Sleeve: #4 MT

Spindle Stroke: 1-3/16″

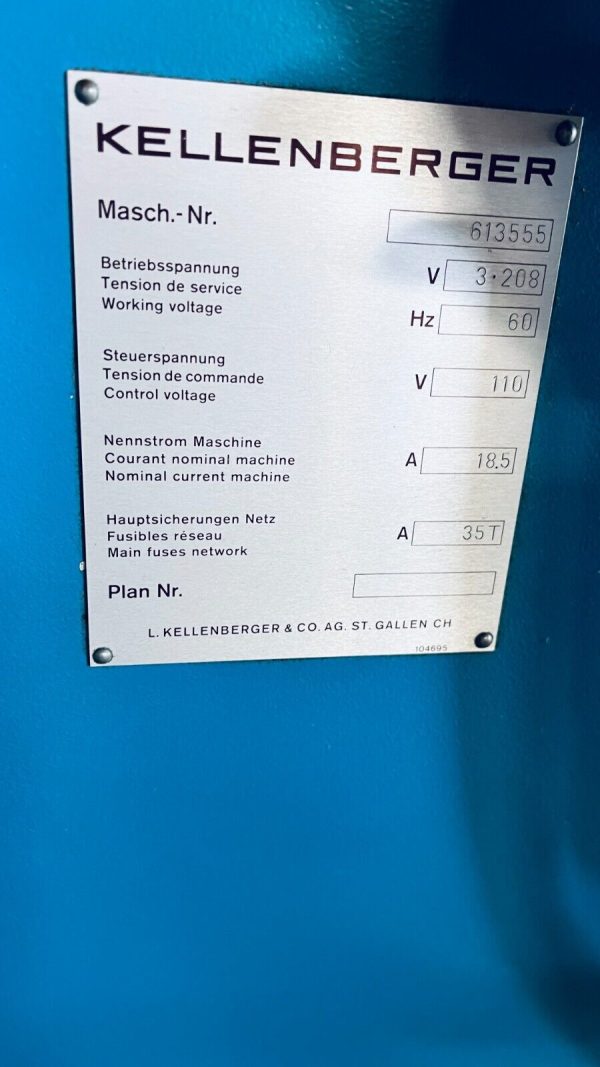

Electrics: 3/60/208 Volts, 6.5 kw

Machine Dimensions: 84″ x 76″ x 66″

Machine Weight: 5,000 lbs

Hydraulic Operation Featuring

-Single Lever Control

-Infinitely Variable Table Traverse

-Automatic Infeed

-Plunge Infeed, Dual Rate, “Rough” & Fine Rate Cross-Over

-Rapid Whell Advance & Retractioon

-Sparkout Timer

-Hydrodynamic Wheelhead Spindle Bearings

*Later Kellenberger Design – Wheelhead Travels on Roller Guided Cross-Slide*

Machine Setup

-Machine is equipped with the OD & ID Grinding Wheelheads. The Face Grinding Wheelguard & Wheel Hub are Available from Kellenberger.

-Wheelhead Swivels Fully around 360 Degrees. Quick Locking of the Wheelhead Swivel is Provided , every 90 Degrees.

-Manual Clamping in any Position. MAnual Swivel on Air Cushion

-Currently Setup as 9.8″ Swing

-Standard Workhead w/ Dual Live & Dead Workhead Spindle

-Seimens DC Motor for Wheelhead, Face Grinding & ID Spindles

-Automatic Power Lube System for Wheelhead & Table Ways

-Coolant Guarding

-Kellenberger Leveling Blocks

Shipping dimensions:

Machine on pallet: 105″ x 72″ x 63″ 5,000 lbs

Pallet w/tanks: 66″ x 56″ x 57″ 960 lbs

Equipped With:

Work Light

Dial Guage Stop for Accurate Seeting of Table Swivel

Gap Control Electronic Control Unit w/ Sensor (Used to Reduce Air Gap Time)

Coolant System with Power Paper Filtration

#5MT Adaptor with Mounting Plate

Fine Taper Adjustment on Tailstock Option

Half Center in Tailstock

Center for Workhead is Provided

Optional Sine Bar for Accurate Setting the Workhead Swivel Angle

Dial Indicator for Table Reversal, Left Side of Table

“Fischer” Model HJN-28 Internal Grinding Spindle (80mm Diameter)

All Available Manuals