Description

Keppler FS 6000 – Year 2009

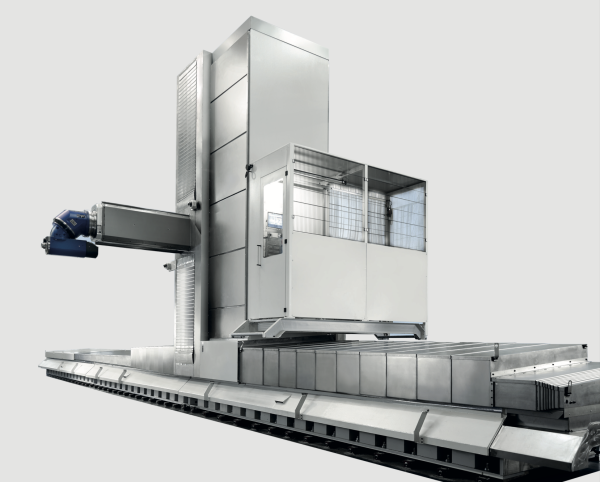

Universal travel machine 5 axis machine Keppler FS 6000

Travel distances

X : 6.000mm

Y : 1.500mm

Z : 2.000mm

CNC control Unit : FANUC 31 i

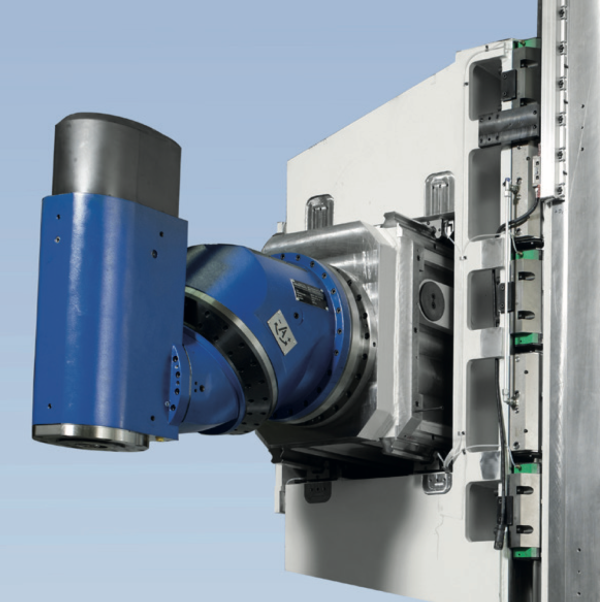

Fray head 2-axis 50kW

Tool holder SK50 Big Plus DIN 69871-1

Fray head A-axis

Swivel angle +/- 190 °

Fray head B-axis Swivel angle +/- 360 °

Spindle speed max. 7.000U / min.

NC round table dimensions 1,600mm x 1,600mm

Plate field 4.000mm x 2.000mm

Tool magazine 40 places

Dismantling 10 000 euros

Delivery to the whole EU possible.

Container Packing possible.

Manufacturer Catalogue Information about Keppler FS 6000

High performance machine travelling column (Model FS) Machines:

Technical data

| Working range | |

| X-axis (mm) | 6000 up to 22000 |

| Y-axis (mm) | 2000 up to 3500 |

| Z-axis (mm) | 1000 up to 1500 |

| Machine table | |

| Clamping surface | in 500mm steps length- and crosswise |

| Rotary table | |

| Clamping surface | from ∅ 1250 |

| Feed drives | |

| max. rapid traverse speed X/Y/Z (m/min) | 20 / Option 30 |

| max. programmable feed X/Y/Z (m/min) | 20 / Option 30 |

| Acceleration | |

| max. acceleration X/Y/Z (m/s²) | 1 m/s² |

| max. acceleration X/Y/Z (m/s²) optional | 2 m/s² |

| NC-milling head | |

| Continuous in both axis or with Hirth-gearing | Option |

| Main drive motor spindle | |

| Rotational speed (rpm) | 5000 / 7000 / 8000 / 10000 |

| Torque (Nm) | 1000 / 600 / 500 / 220 |

| Tool changer | |

| Tool pockets | 40 / 60 / 80 Option up to 250 |

| Tool holder | SK50 (DIN 69871) |

| HSK 100 A (DIN 69893) | |

| Control | |

| Path control | Heidenhain TNC 640 |

| Siemens 840D SL | |

Option

- Spindle- and tool holder according to customer wish

- Machine table in 500 mm steps length- and crosswise

- Rotary table with customer specific dimensions

- Partial enclosure

- Full enclosure

- Oil emulsion separator for full enclosure

- Internal cooling through spindle – Increase to 60 bar

- Blower through the spindle centre

- External blower

- Spray gun

- Minimal quantity lubrication through spindle

- Work piece measurement system (sensing device)

- Tool breakage monitoring

- Tool coding

- Rotating viewing window

- Track flushing

- Manual operating module

- Special designs according to customer specification