Description

Kuka KR16 L6 ARC-C Industrial Robot – Year 2017

| Application type | Welding |

| Number of axis | 6 |

| Reach in mm | 1911 mm |

| Payload in kgs | 6 kg |

| Control type | KUKA KR C2 |

| Kuka KR16 L6 ARC-C | Industrial Robot |

| Worked hours | 50 hours |

Technical parameters of the KUKA KR16 L6 ARC-C welding robot

– number of axles: 6

– arm reach: 1911 mm

– maximum load capacity: 6 kg

– additional load on arm/connecting arm/swivel column: 10 kg/variable/20 kg

– total distributed load: 36 kg

– range of movements of the robot’s axis

axis A1 : ± 114°

axis A2 : + 35° / -155°

axis A3 : + 154° / -130°

axis A4 : ± 350°

axis A5 : ± 130°

axis A6 : ± 350°

– the speed of the robot’s axis movements

axis A1 : 156°/s

axis A2 : 156°/s

axis A3 : 156°/s

axis A4 : 335°/sec

axis A5 : 335°/sec

axis A6 : 647°/s

– repeatability (ISO 9283): ± 0.1 mm

– mounting flange: A6 DIN ISO 9490-1-A40

– assembly: floor, ceiling

– working hours: 50 h

– weight of the KR16 L6 ARC-C robot: 250 kg

Technical data of the PO-2t6m-01 rotary positioner

– load capacity on the turntable: 1040 kg

– total load capacity: 2000 kg

– axis position relative to the ground: 1407 mm

– position of the axis relative to the connector: 1082 mm

– spacing between discs: 6350 mm

– base width: 960 mm

– lifting shackle capacity: 3.25 t

– recommended number of anchors for fixing the positioner to the ground: 38 pcs.

– ambient temperature of the control cabinet: 3-35 °C

– control cabinet power supply: 3x 400 V; 50 Hz

– dimensions (length x width x height): 7887 x 2000 x 2407 mm

– weight of the turntable: 960 kg

– total weight: 3900 kg

– total weight with load capacity: 4940 kg

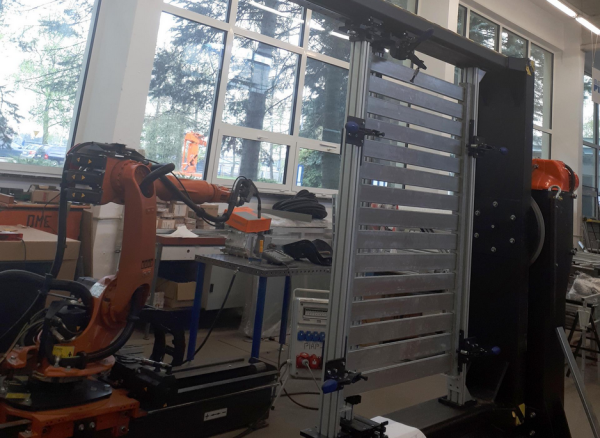

The KUKA KR16 L6 ARC-C robotic welding station with the PO-2t6m-01 rotary positioner was launched in 2017 and worked for a total of 50 hours. Previously, the welding robot arm built in 2009 was used only for testing. The entire welding station has been specially designed for very precise welding of gates and fence spans, but it can also weld various types of structures that fit within the positioner.

The KUKA KR 16 L6 ARC-C robotic welding system is equipped with:

– robot arm: KUKA KR16 L6 ARC-C

– controller: KUKA KR C2

– software: KUKA System Software (KKS)

– current source: FRONIUS TransPuls Synergic 4000 CMT R

– wire feeder: FRONIUS ROBACTA DRIVE CMT

– burner cleaning device: TBi BRG-2-ES-DAE

– rotary positioner: PO-2t6m-01

– track

The track-guided KUKA KR16 ARC welding robot has a reach of up to 6 m and a robust arm with 6 dynamic axes driven by an electromechanical system with brushless AC servomotors. High axial speed combined with small dimensions and weight guarantee excellent precision and the highest quality of welds, even in hard-to-reach places. The robot is controlled by a KUKA KR C2 controller with many useful functions, which significantly increases the productivity and efficiency of the machine.

Directly on the body of the welding torch, the FRONIUS ROBACTA DRIVE CMT feeder is mounted, which supports all welding processes by very dynamic and precise feeding of the electrode wire. The torch of the machine is cleaned of impurities by the TBi BRG-2-ES-DAE cleaning device, which cuts off the end of the wire, sprays anti-spatter liquid on the torch head in a closed spray chamber and removes spatter by a rotating reamer.

The PO-2t6m-01 manipulator has been adapted to rotate elements with a maximum weight of 2 tons and a length of 7 meters, in order to make welded joints. The turntable consists of a connector, a gear motor, a reaction arm, a control cabinet, a sensor mounting assembly and two bodies made of welded sheet, in which the positioner shafts with bolted discs are placed. A rotary table is attached to the discs, centered with pins inserted directly into the holes in the bearing shafts.