Description

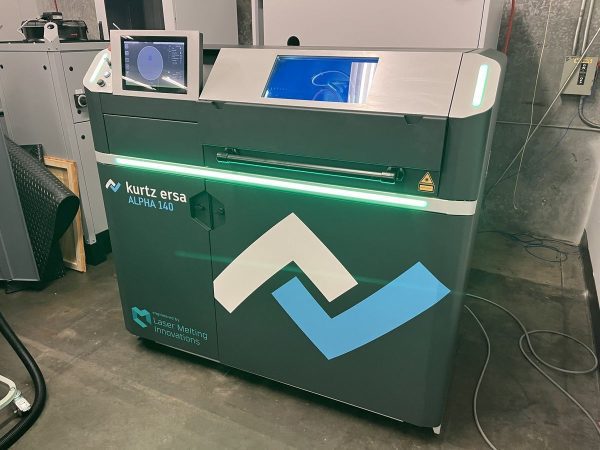

Kurtz Ersa Alpha 140 Metallic 3D Printing – Year 2022

Brand: Kurtz Ersa

Model: Alpha 140

Year: 2022

Approx. Shipping Weight: 2,000 Lbs.

Loading Fee: Rigging Required

Specifications

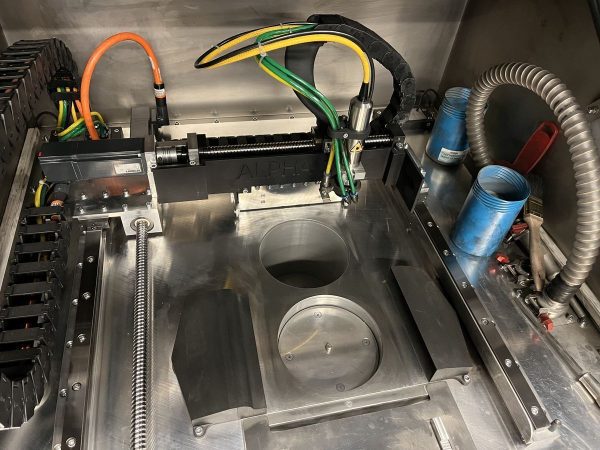

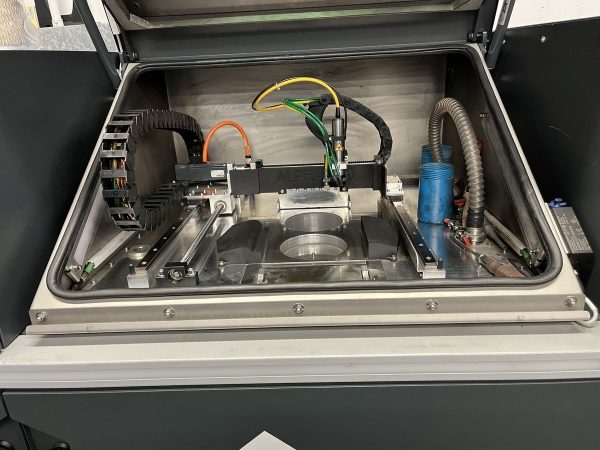

Build Volume: 140mm x 200mm

Layer Height: 30-90 µm

Laser: IPG Fiber Laser 200 W / aircooled

Wavelength: 1070 nm

Focus Diameter: 140 µm

IP Protection Class: IP54

Part Denisty: 99.9%

Power Requirements: 480V / 3 Phase

Equipped With

Internal Nitrogen Generator, Integrated Depowdering Vacuum, Print Plates, Grounding Mats, Metal Powder

Manufacturer Catalogue Information :

The Alpha 140 combines innovative additive manufacturing technology with particularly simple operation at low system costs. The Alpha 140 thus offers an optimal solution for the tool-free production of metal parts, especially for small and medium-sized companies. Complex structures with the greatest geometric freedom can be mapped quickly and cost-effectively. Thanks to the open system, the customer can independently set the process parameters in the slicer according to his individual requirements. A wide range of usable metal materials is thus available through the free variation of process parameters.

Perfect match – LMI and Kurtz Ersa

The cooperation between Laser Melting Innovations GmbH & Co. KG (LMI), based in Aachen, and Kurtz Ersa is taking metallic 3D laser printing further. Together, they offer a cost-effective entry point for medium-sized businesses that benefit from the highest quality and very fast availability. At the same time, the Alpha 140 remains adaptable and can be tailored to customer needs.

Option: Integrated Nitrogen Generator

For the integrated nitrogen generator, compressed air from the customer’s side is connected to the rear of the Alpha 140. In the nitrogen generator, nitrogen is generated from the connected compressed air via a membrane and used for the flooding or printing process. This means that no inert gas bottles need to be connected. The nitrogen circulates via a circulating pump from the pressure chamber via a filter back into the pressure chamber. To compensate for losses, nitrogen is replenished over time. Simple, process-safe and independent of an inert gas infrastructure!

Option: Integrated Depowdering

The integrated depowdering enables the removal of non-fused powder directly in the 3D printer. With the integrated depowdering, this can be done comfortably with the cover closed, and no personal protective equipment (PPE) is required during the powder removal process. Glove grips are mounted on the hood of the Alpha 140. Through these, the operator can depowder in the pressure chamber with the aid of an extraction lance. Extracted powder is collected in the powder collecting container. This powder can then be sieved and reused. Smart and sustainable!