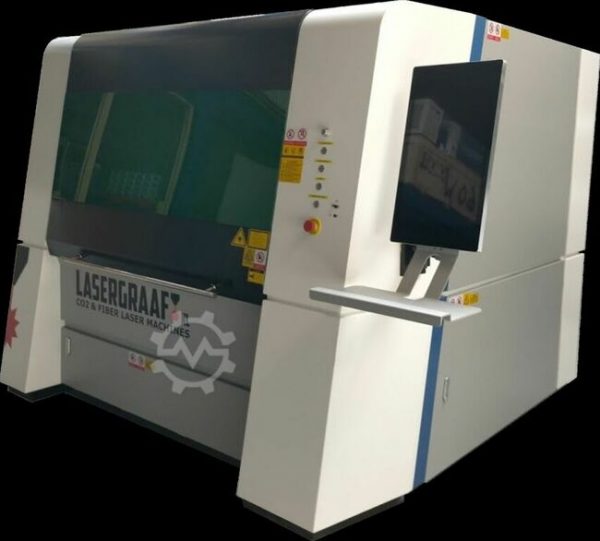

Description

With fiber laser Kristel / LF1390 (format 130 x 90 cm.) You can cut effortlessly through metals such as steel, stainless steel (stainless steel), copper, titanium and aluminum with high speed and ultra-precision. The fiber laser is extremely powerful, is up to 6 times faster than a CO2 laser and consumes about 80% less power. Kristel is available in different powers from 300 to 2000 Watt and cuts up to 16 mm. thick steel.

This machine is equipped with a feed-through function, which means that large metal plates can also be pushed through and processed. Metal plates of 200 x 100 cm and 250 x 125 cm are therefore no problem.

always safe and secure

Kristel is the safest fiber laser machine in its class and ideal for schools, SMEs and small workshops. This fiber laser can be placed anywhere. So it is with this machine no need to wear extra personal protective equipment or to take other measures.

including free remote control

Kristel comes with radio remote control for quick and easy positioning in X, Y and Z direction, The remote control also gives direct access to the functions: automatic focus height search, auxiliary gases blow through, dry testing, contouring, pausing and stopping.

You will soon notice that you can work more efficiently and precisely with the remote control and never want to go without it again. The remote control is magnetic and can be hung anywhere on the machine.

including computer controlled cooling tower

Cooling is very important for your fiber laser, so we supply a very high-quality fully automatic cooling machine with 2 separate cooling circuits. As a result, the laser source and the laser head with the lenses are kept separately and very precisely at their own temperature.

The cooling tower is fully pre-programmed and pre-installed and is operational within 10 minutes. Naturally, the cooling tower communicates directly with the laser machine. In the event of an alarm, the chiller will immediately switch off the laser source to prevent damage to the laser.

including extraction system or automatic filter system (option)

You don’t want to leave metal vapors in the workshop. That is why this fiber laser comes standard with a very powerful cyclone volute extraction system with which all vapors are extracted directly from the machine and blown to an existing filter system or to the outside.

Optionally, fiber laser Kristel can also be equipped with our digitally controlled HEPA recirculation filter systems, which saves a lot of energy and completely relieves the environment. There is even a VAMIL on these machines environmental subsidy possibly causing the costs to be very low.

very extensive software including training

Kristel comes standard with the very powerful CYPCUT controller system for programming your cutting jobs. Cypcut works intuitively enough to get started right away, but has many professional functions, which you normally have to buy separately, already built-in. So has cypcut automatic nesting functions to efficiently organize plates, extensive lead in / out options, micro joints, fly-cutting , pierce functions and extensive cutting settings. Of course you can directly control almost all possibilities of the fiber laser from cypcut. For example, you can control the entire CNC system, regulate gas types and pressures, control the laser source remotely and possibly take over a BCS100 system.

complete installation and on-site training

Kristel is installed on site by our own technicians as standard. Fiber lasers are extremely complex and must of course also be precisely programmed and calibrated during installation. Our technicians can rely on very specific training and experience.

After installation, the technician will first create a complete materials library for you and you will also receive the 1st training and explanation of the machine from our technician. We do the training in the language that you prefer, or in the Dutch, English, German, French, Russian or Chinese.

automatic computerized height controller

The BCS100 is an advanced system to automatically and dynamically adjust the height of the laser head above the metal sheet – even while cutting. The quality of the cutting edge stands or falls with good height control, which is why we chose the best possible combination of Cypcut and BCS100 at lasergraaf. curved and curved plates are no longer a problem. The laser head measures thousands of times per second and automatically follows the plate.

automatic plate-edge detection

With the built-in BCS100 system it is also possible to have the edges of the sheet material searched fully automatically and the software to automatically compensate for skewed plates. Never askew again cut objects or cut next to the plate.

Finally, the system is equipped with extensive self-checking and self-calibration, so that the system fully adjusts and automatically adjusts itself.

Intelligent laser head with “pre-sense” technology

Material that blocks the laser path? Cut pieces that pop up? Plates that are not flat? No problem with the standard built-in automatic control. This machine is equipped with a Swiss Raytools cutting head that measures where it is relative to the material thousands of times per second. If the material is curved or warped, the Raytools head follows the material effortlessly to within 0,003 mm.

automatic ventilation monitoring

When cutting metals you sometimes use pure oxygen. Oxygen is a good oxidizer, but can also be explosive under certain conditions, and irritating fumes are generated during the cutting process. This machine is therefore also equipped with a ventilation monitoring system as standard, so that the laser is automatically blocked if no air extraction is measured in the machine.

PRE-Crash detection

When cutting loose shapes, the object sometimes rises or tilts, causing a crash with the laser head. No problem for our automatic control. The raytools cutting head with built-in intelligence sees a crash hazard well in advance and automatically stops before accidents happen. The laser head moves to a safe position, and the traffic light on the machine signals the machine operator to straighten or remove the tilted material.

computer controlled solid state laser source

Of course, the laser source is the heart of the fiber laser machine and of course we only choose the best of the best. We recommend the Raycus fiber laser sources as standard. These systems are very stable and have one MTBF of up to 80.000 hours. Optionally, we can also implement the machine with an IPG laser source for highly reflective materials. These brands lead the top of the fiber laser market.

The laser source itself is completely solid-state, so no moving parts and completely maintenance free. The powerful built-in computers fine-tune the pulse frequencies, pulse lengths and power curves.

Wireless control & Hi-Res monitor

The operation of the machine is very simple and runs on built-in as standard windows OS operating system and the very powerful cypcut controller system. Everything can be set up and started clearly and intuitively via the wireless keyboard, mouse and handheld.

This machine is already equipped with the portrait high resolution operating & control screen on the swivel arm as standard.

Of course you can cut metal laser with auxiliary gases. With the fiber lasers you preferably use oxygen, nitrogen or argon (and in some cases compressed air) depending on the type of material and the thickness of the material. In addition, high power fiber lasers have some wearing parts that need to be replaced periodically. All in all, Kristel cuts for example 3 mm. steel for about 4 Euro per hour and 1 mm. stainless steel for around 7 Euro per hour. (based on 500 Watt fiber source and depending on gas purchasing costs, and costs per Kwh power).

dimension: 2110 * 2160 * 1630mm

weight: 1500-1800 Kg

max speed: 40 m / min

integrated red-dot contour laser

O2: max 900 Kpa

N2: max 1.100 Kpa

tension :

500 Watt: 220 volts / 25 Amp + 220 volts – 16 amp (cooling)

700+ Watt: 380 volts / 40 Amp + 220 volt – 16 amp (cooling)

repeat accuracy: 0,01 mm.

Cypcut CNC control system

including industrial computer system

including radio remote control

For this machine we strongly advise to use the following HEPA filter installation that cleans and recirculates the air. Healthier working air, cheaper work and no environmental permit required (as may be the case when blowing out