Description

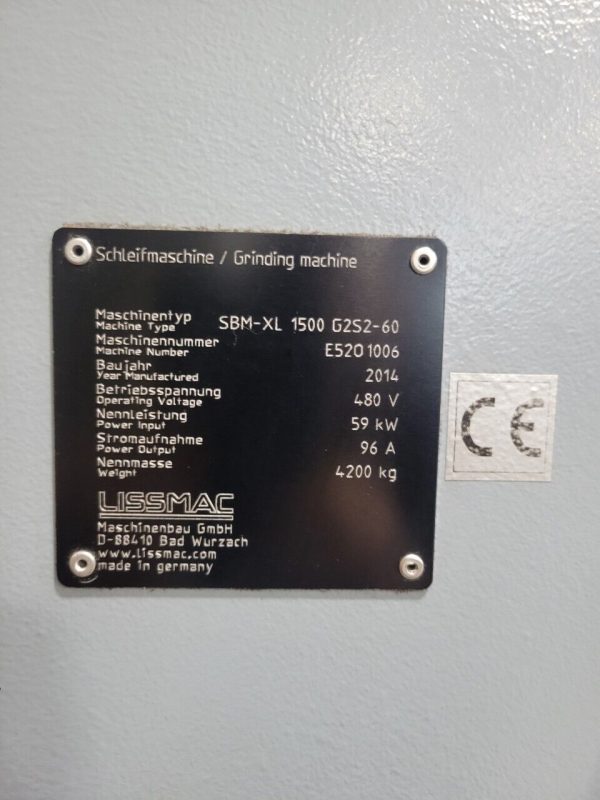

Lissmac SBM-XL 1500 G2S2-60 – Year 2014

Edge Rounding and Deburring Machine

The SBM-XL S2B2 grinding and deburring machine is designed for edge rounding and oxide layer removal from steel and stainless steel parts in one operation. The LISSMAC system is suitable for processing laser parts.

By removing the oxide layer, the sheet metal parts are perfectly prepared for subsequent processes such as coating. The technology gives improved surface quality on steel parts. The system also guarantees consistent processing quality when deburring and edge rounding. The processing units of the double-sided grinding and deburring machine can be switched on and off separately. The mechanical process also ensures optimal ergonomics for deburring and edge rounding, making the job easier for the operator.

Specifications:

2″-60″ WORKING WIDTH

0″-4.72″ WORKABLE MATERIAL THICKNESS

660 LB LOAD

0-13 FT/MIN INFINITELY VARIABLE FEED SPEED

ELECTRIC ADJUSTMENT OF MATERIAL THICKNESS

ELECTRIC ADJUSTMENT OF TOOLS

IP 42 INSULATION CLASS

FEATURES

– DEBURRS AND EDGE ROUNDS WORKPIECES

CUT BY PLASMA AND THERMAL PROCESSES

– A SINGLE PASS SIMULTANEOUSLY PROCESSES THE TOP

AND BOTTOM, INTERIOR AND EXTERIOR CONTOURS

– DRY OPERATION

– SIMPLE INTUITIVE OPERATION

– PROCESSING UNITS CAN BE INDIVIDUALLY ADJUSTED

– MAXIMUM PRODUCTIVITY & QUALITY MACHINING

– CROSS-MACHINING FOR OPTIMUM TOOL UTILISATION

– FAST, SIMPLE TOOL CHANGE WITHIN MINUTES

– MODULAR, COMPACT SMALL FOOTPRINT

– REDUCED DUST, DIRT AND NOISE

Dimensions:

142″ X 83″ X 80″

Weight:

9,260

FURTHER INFORMATION

Edge rounding and oxide removal of laser cut parts

Two-side edge rounding and oxide removal saves the cost intensive turning of often very heavy workpieces or machining of parts twice

Consistent edges on all outside and inside contours

Dry operation

Simple, intuitive operation

The processing units can be individually adjusted or turned on and off electrically.

Maximum productivity while maintaining machining quality

The cross-machining principle guarantees optimum tool utilisation over the entire working width.

Faster and simpler tool change within just a few minutes

Modular and compact in modern machine design – smaller footprint

Improved work environment – Reduction of dust, dirt and noise

Optionally available: Conveyor Technology; Handling Systems, Automation; Custom Solutions

For repeated customer requirements, processing parameters can be called up quickly and easily through predefined programs.

Up to 60 % work time savings compared to one-side processing grinding machines