Description

LNS Hydrobar Sprint S3 Automatic Magazine Bar Feeder Fixed Headstock Lathes – Year 2014

2014 LNS SPRINT S3 used magazine type bar loader. Features a 3.125″ capacity and accommodates bar lengths up to 12′. Ideal for efficient material handling with proven LNS quality.

Specifications

Capacity 3.125″

Bar Length 12′

Equipped With

Crate of tooling

AUTOMATIC MAGAZINE BAR FEEDER FOR FIXED HEADSTOCK LATHES

Diameter range: 1/2” to 3 – 1/8”

(12.7 mm to 80 mm) Overall barstock length: 12’6”

YOUR “ONE-STOP-SHOP”

FOR MACHINE-TOOL PERIPHERALS

LNS America has set the industry standard in bar feed systems. The Hydrobar Sprint S3 is incredibly efficient and undoubtedly reliable. Designed to safely handle a complete range of sizes, high speed operation, greater workpiece accuracy, shorter machining times, quiet, vibration-free performance, unattended operation, superior surface finish, longer tool life and lower running costs. Hexagonal and square bar stock can also be accommodated.

Maximizing Your Spindle Speed For Efficiency

Unsupported bar stock turning at high RPMs produces poor output and over a period of time can cause damage to your barfeed and lathe.

The Hydrobar Sprint S3 features a patented hydrostatic self-opening bearing block design, permitting you to run round bar stock at your lathe’s maximum spindle speed and it guarantees the best bar support in the industry. The Hydrobar Sprint S3 hydrostatic bearing element design is capable of continuous operation at maximum RPM’s.

Its high speed capability also permits full implementation of constant surface speed cutting operations up to 3000 SFM. Pressurized oil penetrates the bearing elements, allowing high speed bar stock rotation.

Designed to Run at High RPMs

When running at high RPMs, the design of a barfeed contributes greatly to the life

of a lathe, surface finish and tool life.

Ruggedly built to ensure long life, the servo driven automatic magazine bar loader requires minimum maintenance and will give you longer tool life.

The bearing support system is a heavy duty cast iron design that provides continuous, quiet, vibration-free operation without fail. The rugged design includes features that withstand the abuse of large bar stock turning at high RPM. These features make the Hydrobar Sprint S3 reliable, easy-to-use and ensure long life for both the bar feed and your lathe.

Extended Run Time Keeps Your Production Running Efficiently

Continuously loading bar stock to keep your production running can become

inefficient. Production time is lost and long run times can result in profit lost.

The combination of high speed operation and automatic loading makes the Hydrobar Sprint S3 the ideal bar feed for integration into automated production cells and systems. It meets the high material usage needs of continuous turning operations and unmanned machining operations.

The Hydrobar Sprint S3 is equipped with a large capacity stock magazine providing uninterrupted operation of CNC lathes on average lot runs and extended runs of any length workpiece.

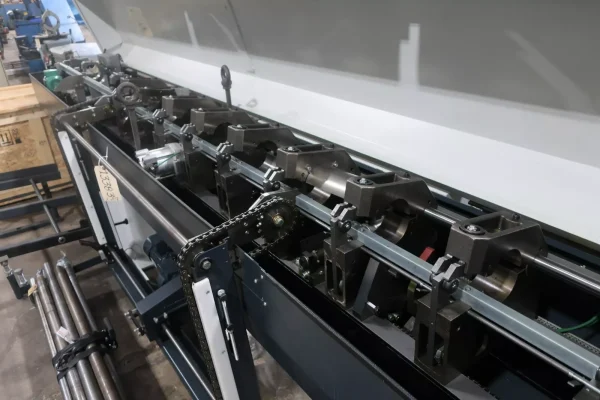

The large capacity (27-1/2“) stock magazine is situated alongside the bar feed system and below the center axis of the machine. Barstock automatically loads from the magazine to a chain loading device which lifts bar stock to the barfeed and advances the bar stock into position.

Intelligent, User Friendly Remote Control For Fast Changevoers

The latest PLC generation offered with the Hydrobar Sprint S3 is user friendly and production efficient. The ultra light, ergonomic remote control provides clear, concise instructions, text messages and unmatched ease of operation. The remote can be unplugged from the cable for ease of servicing.

To control torque and speed, all you need to do is enter the bar diameter and length of the workpiece in the remote control. This operation takes approximately fifteen seconds for diameter change. Adjustments are made automatically. No manual adjustments are required. Complete changeover is fast and easy and achieved in approximately 10 minutes, includes quick change bearing elements and pusher, bearing elements handle a full .157” diameter range.

Maximum speed is based on round steel bar straight within .020”/3 ft. with diameter clearance of .020” rotational clearance between bearing elements and bar stock. For relative speeds using other materials, contact manufacturer.

Specifications subject to change without notice

HYDROBAR SPRINT S3 BARFEED

TECHNICAL SPECIFICATIONS

Bar stock must be prepared with a chamfer of 60° included angle at one end, and should be straight within .020”/3ft.

Barstock Straightness Specifications and Performance

For optimum rotational performance speeds, bar stock straightness needs to be .020” per 3.25 feet, non accumulative. Bar stock out of this tolerance will not run at optimum RPM. Other factors such as material type (brass, copper, bronze and other malleable materials), clamping efficiency of the machine workholding, alignment of the bar feed, oil type, bar preparation and spindle liners will affect optimum RPM capability of the system.

AUTOMATIC MAGAZINE BAR FEEDER FOR FIXED HEADSTOCK LATHES

Diameter range: 1/2” to 3 – 1/8”

(12.7 mm to 80 mm) Overall barstock length: 12’6”

LNS America has set the industry standard in bar feed systems. The Hydrobar Sprint S3 is incredibly efficient and undoubtedly reliable. Designed to safely handle a complete range of sizes, high speed operation, greater workpiece accuracy, shorter machining times, quiet, vibration-free performance, unattended operation, superior surface finish, longer tool life and lower running costs. Hexagonal and square bar stock can also be accommodated.

Maximizing Your Spindle Speed For Efficiency

Unsupported bar stock turning at high RPMs produces poor output and over a period of time can cause damage to your barfeed and lathe.

The Hydrobar Sprint S3 features a patented hydrostatic self-opening bearing block design, permitting you to run round bar stock at your lathe’s maximum spindle speed and it guarantees the best bar support in the industry. The Hydrobar Sprint S3 hydrostatic bearing element design is capable of continuous operation at maximum RPM’s.

Its high speed capability also permits full implementation of constant surface speed cutting operations up to 3000 SFM. Pressurized oil penetrates the bearing elements, allowing high speed bar stock rotation.

Designed to Run at High RPMs

When running at high RPMs, the design of a barfeed contributes greatly to the life

of a lathe, surface finish and tool life.

Ruggedly built to ensure long life, the servo driven automatic magazine bar loader requires minimum maintenance and will give you longer tool life.

The bearing support system is a heavy duty cast iron design that provides continuous, quiet, vibration-free operation without fail. The rugged design includes features that withstand the abuse of large bar stock turning at high RPM. These features make the Hydrobar Sprint S3 reliable, easy-to-use and ensure long life for both the bar feed and your lathe.

Extended Run Time Keeps Your Production Running Efficiently

Continuously loading bar stock to keep your production running can become

inefficient. Production time is lost and long run times can result in profit lost.

The combination of high speed operation and automatic loading makes the Hydrobar Sprint S3 the ideal bar feed for integration into automated production cells and systems. It meets the high material usage needs of continuous turning operations and unmanned machining operations.

The Hydrobar Sprint S3 is equipped with a large capacity stock magazine providing uninterrupted operation of CNC lathes on average lot runs and extended runs of any length workpiece.

The large capacity (27-1/2“) stock magazine is situated alongside the bar feed system and below the center axis of the machine. Barstock automatically loads from the magazine to a chain loading device which lifts bar stock to the barfeed and advances the bar stock into position.

Intelligent, User Friendly Remote Control For Fast Changeovers

The latest PLC generation offered with the Hydrobar Sprint S3 is user friendly and production efficient. The ultra light, ergonomic remote control provides clear, concise instructions, text messages and unmatched ease of operation. The remote can be unplugged from the cable for ease of servicing.

To control torque and speed, all you need to do is enter the bar diameter and length of the workpiece in the remote control. This operation takes approximately fifteen seconds for diameter change. Adjustments are made automatically. No manual adjustments are required. Complete changeover is fast and easy and achieved in approximately 10 minutes, includes quick change bearing elements and pusher, bearing elements handle a full .157” diameter range.

Maximum speed is based on round steel bar straight within .020”/3 ft. with diameter clearance of .020” rotational clearance between bearing elements and bar stock. For relative speeds using other materials, contact manufacturer.

Specifications subject to change without notice

HYDROBAR SPRINT S3 BARFEED

TECHNICAL SPECIFICATIONS

Bar stock must be prepared with a chamfer of 60° included angle at one end, and should be straight within .020”/3ft.

Barstock Straightness Specifications and Performance

For optimum rotational performance speeds, bar stock straightness needs to be .020” per 3.25 feet, non accumulative. Bar stock out of this tolerance will not run at optimum RPM. Other factors such as material type (brass, copper, bronze and other malleable materials), clamping efficiency of the machine work holding, alignment of the bar feed, oil type, bar preparation and spindle liners will affect optimum RPM capability of the system.