Description

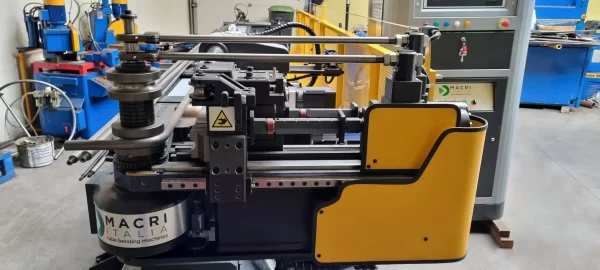

MACRI ITALIA PROVAR 6-45 U-D – Year 2019

Tube and Profile Bending machine

Specifications of MACRI ITALIA PROVAR 6-45 U-D tube and profile bending machine

number of axes: 6 (X, Y, Z, B1, B2, A)

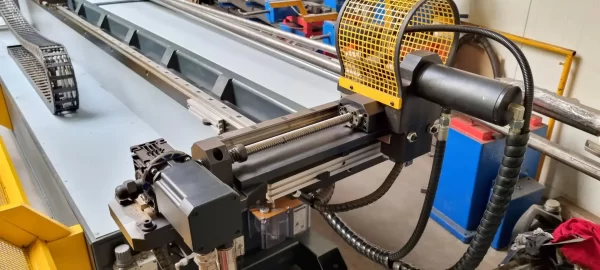

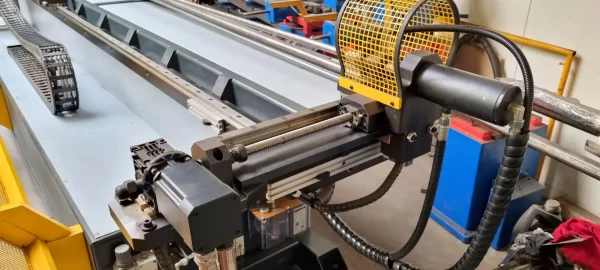

maximum workpiece length: 5800 mm

maximum workpiece diameter: 45×4 mm

maximum workpiece diameter (variable radius min. RM 10D): 35×2 mm

traverse speed (X axis): 1000 mm/1″

bending speed (Y axis): 150°/1″

clamp rotation speed (Z axis): 450°/1″

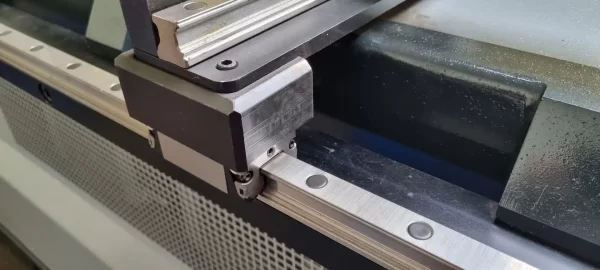

tolerance in X axis: ± 0.1 mm

tolerance in Y, Z axes: ± 0.1°

rotation direction: clockwise

installed power: 15 kW

power supply: 400 V; 50 Hz

dimensions (L x W x H): 6000 x 1200 x 1200 mm

control cabinet dimensions (L x W x H): 900 x 600 x 1800 mm

PROVAR 6-45 U-D machine weight: 4200 kg

Equipment of the mandrel bending machine

software: MACRI

axes brushless servomotors

control cabinet with industrial PC (Windows 10, 512 MB RAM, 19 TFT SVGA touch screen display, keyboard, mouse, USB port, RS232 port)

special support for bending without stabilising bars

support for anti-cracking cap

movable slide support

central cylinder for opening the dies (multiple levels)

complete tool for the selected tube diameter (3 levels)

upper die opening cylinder (1 level)

cooling unit

automatic lubrication of the mandrel

aluminium safety mat

MACRI ITALIA PROVAR 6-45 U-D bending machine was manufactured in 2019 in Italy. The fully automatic mandrel bending machine is used in the process of machining tubes and profiles with a maximum diameter of 45 mm in 6 numerically controlled axes (X, Y, Z, B1, B2, A). Excellent process stability and workpiece quality, with the possibility of bending standard and variable (free) radiuses, are guaranteed thanks to the robust steel construction, the moving head with high-strength gears and the equipping of all machine axes with brushless servomotors.

The MACRI PROVAR 6-45 U-D tube bending machine is controlled using state-of-the-art MACRI software with the ability of importing files from 3D programmes and performing an anti-collision test with 3D simulation, programming of positioner force and automatic mandrel lubrication and many other useful functions. The total weight of the machine is 4200 kg.