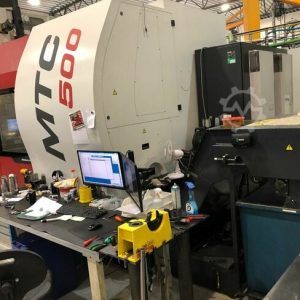

Description

Mazak Integrex 200 III-ST – Year 2005

5 axis simultaneously and 5 axis free form – CAP Tool system!

Accumulated time:

Power on: 2026: 04’40 ”

Auto open: 1323: 07’43 ”

Auto cut: 669: 16’50 ”

Total cut: 5606: 49’54 ”

Total time: 2028: 04’40 ”

Bought new from Mazak factory.

Excellent and working condition.

Comes with different machining tools.

You’re welcome to test and see the machine.

Year of manufacture: 10-2005

– Max. Swing diameter ……………. …… Ø660 mm

– Max machining diameter (upper / lower turret) ……… ..Ø660 mm / Ø270 mm

– Max. Machining length …………… ….… 1016 mm

– X – axis travel (upper turret) …………… … ………… .580 mm

– X2 – axis travel (lower turret) …………… .150 mm

– Z-axis travel (upper turret) …………… …..… ..1045 mm

– Z2 – axis travel (lower turret) …………….… .990 mm

– B – axis traverse path …………. …………….… .225 °

– C – axis travel ……………… 360 °

– Chuck size …………… … 8 ”

– Main spindle speed …………… ..… .5000 o / min

– Main spindle bore …………… … ……………. Ø51 mm

– Min. Main spindle indexing …………… .. ………… 0.0001 °

– Chuck size 2nd spindle …………… .. ………… .. 8 ”

– Speed of the 2nd spindle …………….… 5000 o / min

– Travel of the 2nd headstock (W axes) …………… .. …… .. 1050 mm

– Rapid traverse speed of the 2nd headstock (W axes) …… .. 30000 mm / min

– Min. Indexing of the 2nd spindle …………… 0.001 °

– Turret type (upper) …………… with ATC

– Tool shank height (upper) …………… ..… .. 25 mm

– Boring bar shank diameter …………… ..… .. Ø40 mm

– Type of revolver (lower) ……………. …… drum revolver with 9 stations

– Number of tools …………….… .. 9 tools

– Tool shank height (lower) ……………. …… .. 25 mm

– Boring bar shank diameter …………… …. Ø32 mm

– Turret indexing time (lower) ……………. 0.14 s / 1 switching step

– Milling spindle speed …………… .. 12000 o / min

– Processing capacity of the milling spindle ……………. Milling: Ø100 mm, shank: Ø32 mm,

Drilling: Ø30 mm, tapping: M27

– Rapid traverse speed: X – axes (upper) …………… 38000 mm / min

– Rapid traverse speed: X 2– axes (lower) …………. …… 38000 mm / min

– Rapid traverse speed: Y – axes …………… 26000 mm / min

– Rapid traverse speed: Z – axes (upper) …………….… 38000 mm / min

– Rapid traverse speed: Z2 – axes (lower) …………… ..… 38000 mm / min

– Rapid traverse speed: C axes …………….… 400 o / min

– Jog feed speed: X – axes (upper) ………. …… 2000 mm / min

– Jog feed speed: X2 – axes (lower) ……… ..… 2000 mm / min

– Jog feed speed: Y – axes (upper) ………….… 2000 mm / min

– Jog feed speed: Z – axes (upper) ………… ..… 2000 mm / min

– Jog feed speed: Z2 – axes (upper) …………… 2000 mm / min

– Jog feed speed: C axes …………….… 2000 ° / min

– Tool shank / tool holder capacity …………… .. CAPTO C6 No 20 tools

– Max. Tool diameter …………… .. Ø90 mm (Ø125 mm with free secondary spaces)

300 mm / 10 kg

– Tool change time (tool-to-tool) …………… .. 1.3 s

– Main spindle motor (30 min – / continuous operation) …………… ..AC 22 kW / AC 15 kW

– Motor of the 2nd spindle (30 min – / continuous operation) …………… …. AC 18.5 kW / AC 15 kW

– Milling spindle motor (20% ED) ……………. AC 15 kW

– Coolant pump motor …………… 1.2 kW

– Power consumption (continuous operation) …………….… .. 66.0 kVA

– Compressed air connection …………… ..… ..5 bar, 500 l / min

– Coolant capacity of the tank …………… ..… .. 300 l

– Machine height …………… .. …… .2597 mm

– Installation area ……………. 3820 x 2212 mm

– Weight …………… .9200 kg