Description

Mazak Super Turbo X48 MK II – Year 2001

CNC laser cutting machine

| Metal length | 2500 mm |

| Power | 1500 W |

| Metal width | 1250 mm |

| Type | CO₂ |

| Option to cut tubes | no |

| Max thickness | 15 mm |

| CNC | yes |

| CNC type | MAZATROL L32B |

| Travel X | 2685 mm |

| Travel Y | 1270 mm |

| Travel Z | 100 mm |

| Max weight of the workpiece | 300 kg |

| Mazak Super Turbo X48 MK II | |

| Weight | 12500 kg |

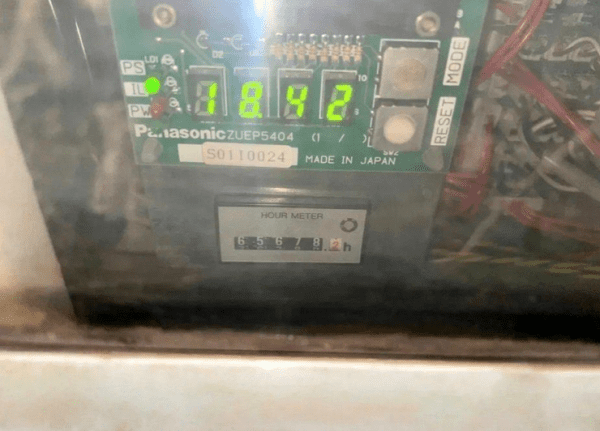

| Worked hours | 65678 hours |

Technical specification of the MAZAK SUPER TURBO X48 MK II laser cutter

– maximum laser power: 1500 W (1.5 kW)

– laser power adjustment range: 300 W – 1500 W

– dimensions of the work table (length x width): 2500 x 1250 mm

– feeds in the X/Y/Z axes: 2685/1270/100 mm

– speed of accelerated feeds in the X/Y/Z axes: 24/24/25 m/min

– positioning accuracy in the X and Y axes: ± 0.01/500 mm

– positioning accuracy in the Z axis: ± 0.01/100 mm

– repeatability in the X/Y/Z axes: ± 0.005 mm

– maximum dimensions of the detail (length x width x height): 2500 x 1250 x 12 mm

– maximum sheet thickness (S235 structural steel): 15 mm

– maximum sheet thickness (stainless steel): 6 mm

– maximum sheet thickness (aluminum): 3 mm

– maximum workpiece weight: 300 kg

– maximum cutting speed: 15 m/min

– laser type: CO2

– wavelength: 10.6 μm

– beam diameter: ⌀ 22.5 mm

– beam spread angle: 0.11°

– chip conveyor feeds (50 Hz/60 Hz): 2.2/2.6 m/min

– working hours of the resonator: 65678.2 h

– power consumption: 25 kW

– weight of the dust collector: 350 kg

– total weight of the SUPER TURBO X48 MK II machine: 12500 kg

Equipment of the MAZAK SUPER TURBO X48 MK II laser

– CNC controller: MAZATROL L32B

– laser source: YB-L150A 8M

– dust collector: ENTSTAUBER LDC-1/1000/13

– X,Y,Z axes servo motors

– chip conveyor integrated with the machine frame

– 7.5″ head

– 3 clamps for fixing sheet metal with a position encoder

– sheet lifting device, 5 mm stroke with rotation

– lighting of the workspace

– Technical Documentation

– nozzle

– spare parts (head cable, solenoid valves)

MAZAK SUPER TURBO X48 MK II laser cutter, manufactured in 2001 in Japan, is a compact laser machine for standard sheet metal formats, suitable for cutting details both in small plants and in mass production. The compact design of the machine includes components integrated with the cutter, such as the YB-L150A 8M resonator, chip conveyor and MAZATROL L32B CNC controller.

The highly energy efficient laser source is adjustable from 300W to a maximum of 1500W, achieving excellent quality, high speed and accuracy of cut across the entire workspace at low operating costs. Sheet metal with a thickness of 15 mm (S235 structural steel), 6 mm (stainless steel) and 3 mm (aluminum) is cut on the large work table of the MAZAK ST-X 48 MKII laser cutter, which is 2500 mm long and 1250 mm wide.

The CO2 laser cutter is offered with a wide range of accessories, including: from the ENTSTAUBER LDC-1/1000/13 dust collector collecting dust and impurities generated during cutting, X, Y, Z axis servo motors and a 7.5″ head. The total weight of the gas cutter is 12,500 kg.