Description

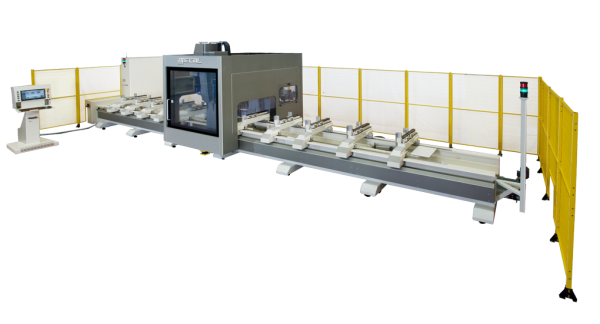

Mecal MC 302 GEOS-5 CNC Profile Milling Machine 5-Axis – Year 2014

| Axis Y | 1570 mm |

| Axis Z | 740 mm |

| Mecal MC302 GEOS-5 | CNC Profile Milling Machine 5-Axis |

| Number of tool pockets | 18 |

| Year : 2014 | |

| Max. spindle speed | 24000 rpm |

| Spindle motor power | 12 kW |

Technical specification of the MECAL MC302 GEOS-5 profile milling machine

– number of axes: 5 (X,Y,Z,A,C)

– feeds in the Y/Z axes: 1570/740 mm

– inclination of the spindle in the A axis: ± 120°

– spindle rotation in the C axis: ± 210°

– accelerated feeds in the X/Y/Z axis: 70/60/40 m/1

– 3D graphics software

– magazine capacity for tools: 18

– maximum speed of the electrospindle: 24000 rpm

– electrospindle power: 12 kW

– maximum blade diameter: 500 mm

– maximum diameter of the side and front cutter: 200 mm

– central lubrication

aluminum alloys, plastics and steel. The machine, equipped with high-class components and innovative solutions, performs processing both on a single working field and inside 2 separate working zones, which translates into a significant increase in the speed and efficiency of the production process. Simultaneous machining on two working zones is possible thanks to the use of a longitudinal working area with a sliding processing station and a chip conveyor.

The MECAL aluminum profile machining center achieves high structural rigidity thanks to the base made of quality steel tubes. During processing, the profile is held by special clamps with an independent power supply system, allowing positioning and automatic repositioning of each single clamp in a very short time. All 5 axes (X, Y, Z, A, C) driven by motors with digital systems, move along automatically lubricated, precise guides. The MECAL GEOS-5 machining center is offered with 3D software, ensuring a high level of programming flexibility, user-friendliness and an intuitive graphical interface.

Manufacturer Catalogue Information about

Mecal MC 302 GEOS – 5 MMI :

5 AXIS CNC FLOOR TYPE VERTICAL SPINDLE MACHINING CENTER.

5 axis (X, Y, Z, C, A) managed by CNC.

MMI = version provided with a device activated by a pneumatic/electronic combination dedicated to the automatic contemporary movement of the clamps.

Suitable for milling, drilling, tapping and cutting on the 5 sides of aluminum, PVC, steel and light alloys profiles; thanks to the 5 axis interpolation, the machine is able to execute composite cuts.

The X or longitudinal axis, the Y or transversal axis and the Z or vertical axis belong to the tool movement. They can be interpolated in linear and circular way on 3-dimension geometrical planes, belonging to X-Y-Z.

The C axis can be turned and positioned on all angles within 420° (± 210°); the A axis can be tilted and positioned on all angles within 240° (± 120°).