Description

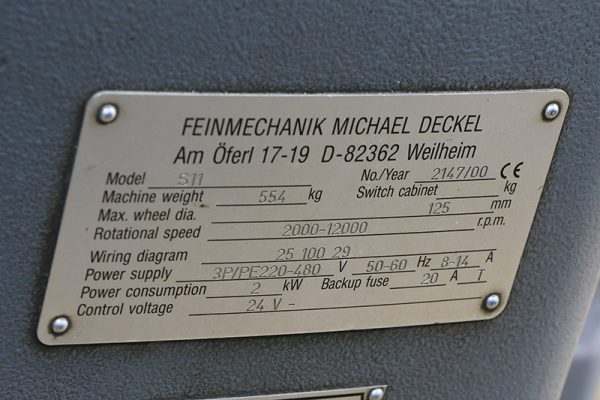

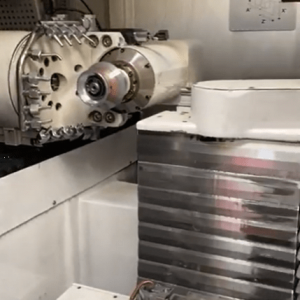

Michael Deckel ISOG S11 SPEED – Year 2000

MICROSCOPE WITH VIDEO SYSTEM TOOL & CUTTER GRINDER

DECKEL (ISOG) UNIVERSAL TOOL & CUTTER GRINDER

ADJUSTABLE THROUGH 360 DEG. IN 5 AXES

MACHINE COMES WITH MANY ACCESSORIES

TYPE: S11 SPEED

S/N: 2147

NEW: 2000

WORTABLE LONGITUDINAL TRAVEL ……………… 7.5″

WORKTABLE CROSS TRAVEL …………………… 4″

SPINDLE, VERTICAL TRAVEL …………………. 13″

SPINDLE AXIAL FEED ………………………. 0.187″

MAX. WORKPIECE DIA. BETWEEN CENTERS ……….. 13.5″

MAX. WORKPIECE LENGTH BETWEEN CENTERS ……… 37″

SPINDLE COLUMN SWIVEL, HORIZONTAL …………. 360 DEG.

SPINDLE COLUMN SWIVEL, VERTICAL …………… 360 DEG.

WORKTABLE SWIVEL ………………………… 360 DEG.

UNIVERSAL INDEX HEAD SWIVE, HORIZONTAL …….. 360 DEG.

UNIVERSAL INDEX HEAD SWIVEL, VERTICAL ……… 360 DEG.

MAX. WHEEL DIAMETER ……………………… 5″

MAX. CUT-OFF WHEEL DIAMETER ………………. 8″

SPINDLE MOTOR …………………………… 1.75 H.P.

SPINDLE SPEED RANGE (RPM) ………………… 2,000 TO 12,000 RPM

MACHINE TOOL DIMENSIONS ………… 43.3″L x 31.5″W x 69.3H

MACHINE TOOL WEIGHT ……………………… 1,145 LBS.

“LISTA” TOOL CABINET DIMENSIONS ……. 22″W x 29″D x 40″H

APPROX. WEIGHT WITH ACCESSORIES …………… 450 LBS.

OPTO-ELECTONIC MEASURING UNIT SPECS:

MEASURING RANGES:

PARALLEL TO TOOL AXIS …………………… 6″

SQUARE TO TOOL AXIS ………………. 2- 1/2″ OR 5″ DIA.

RADII ………………………………… UP TO 1/8″

FIELD OF VIEW …………………………. 1/4″

MAXIMUM DISTANCE OF MEASURING POINT TO

INDEX SPINDLE END FACE:

INDEX SPINDLE END FACE …………………. 6- 3/4″

WITH ADDITIONAL EXTENSION ………………. 10- 5/8″

MAGNIFICATION ………………………….. ZOOM LENS

THIS MACHINE IS EQUIPPED WITH MANY DECKEL ACCESSORIES:

DESCRIPTION OF SOME OF THE MAJOR ACCESSORIES:

“MEASURING UNIT” WITH MICROSCOPE (2658014). UNIT INCLUDES

DIGITAL READOUT DISPLAY, AND VIDEO DISPLAY.

ALLOWS FOR PRECISE & COMFORTABLE MEASUREMENTS PARALLEL & SQUARE TO THE TOOL AXIS. WITH THE HELP OF THE

RETICULE IN THE LENS YOU CAN ALSO DETERMINE RADII & ANGLES WITH GREAT ACCURACY.

THE MICROSCOPE DOES NOT REQUIRE BACKLIGHTING.

IT ALSO ALLOWS UNOBSTRUCTED MEASUREMENT OF TOOLS THAT ARE MOUNTED IN THE TAILSTOCK BRACKET & OFFERS MORE FREEDOM OF MOVEMENT.

THE 3-DIMENSIONAL REPRESENTATION PERMITS YOU TO JUDGE TOOL FORM & SURFACE PRECISELY.

VIDEO CAMERA & MONITOR, ALLOWING THE OPERATOR GRETATER FLEXIBILITY.

DRASTICALLY REDUCED TIMES, MEASURING IN THE MACHINE, NO CHANGE

BETWEEN THE MACHINE AND THE DESK, NO CLAMPING ERRORS, WHICH ARE

NORMALLY INEVITABLE AFTER UNCLAMPING & RECLAMPING, IMPRESSIVE REPEAT

ACCURACY, THE OPTION OF CONSTANTLY CHECKING THE GRINDING PROCESS

TO GUARANTEE THE DESIRED WORK QUALITY.

STANDARD UNIVERSAL INDEX HEAD #ST 40 (DECKEL PART #2555201)

WITH CONNECTION FOR OPTO-ELECTRONIC MEASUREMENT SYSTEM.

INSTRUCTION MANUAL FOR THE MICROSCOPE & VIDEO CAMERA:

MOTOR DRIVE FOR UNIVERSAL INDEX HEAD (DECKEL PART #2667000)

PROVIDES INFINITELY VARIABLE SPINDLE SPEEDS FROM 100 TO 1,000 RPM. UNIT ALSO HAS A SWITCH FOR FORWARD & REVERSE.

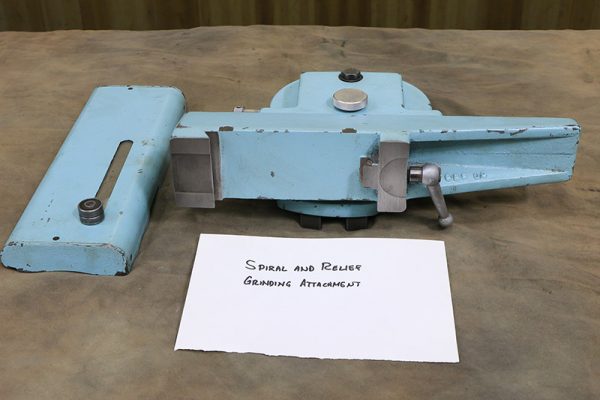

“SPIRAL & RELIEF GRINDING ATTACHMENT” (DECKEL PART #2580000)

FOR GRINDING TOOLS WITH R.H. OR L.H. FLUTES& FOR RELIEF

GRINDING OF COUNTERBORES, TAPS, SPADE DRILLS& PROFILED

CUTTERS, THE UNIVERSAL INDEX HEAD CAN BE COMBINED WITH

THE TWIST& RELIEF GRINDING ATTACHEMENT. IT’S LEAD RANGE

IS FROM 0 TO INFINITY. THE RELIEF GRINDING MOTION CAN BE

AXIAL, RADIAL OR A COMBINTION OF THE TWO.

RELIEF GRINDING SLIDE (DECKEL PART No. 2673000).

STROKE LENGTH 50mm (2″) FOR AXIAL-RADIAL RELIEF GRINDING WITH DIRECT FEED

TO TOOL IN TWO DIRECTIONS.

“RADIUS GRINDING ATTACHMENT” (DECKEL PART #2601000).

RADIUS ATTACHEMENT DESCRIPTION:

CONVEX& CONCAVE RADII ON TOOLS STRAIGHT, BEVELLED &

SPIRAL FLUTES, OR ON SINGLE-LIP CUTTERS AND ON TURNING

TOOLS ARE NO PROBLEM. WITH IT, YOU CAN ALSO GRIND THE

CURVED FLUTES OF DIE SINKING CUTTERS TO THE CORRECT ARC.

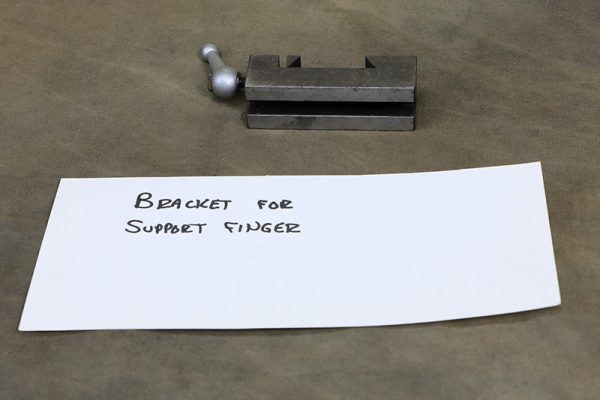

WITH THE HELP OF THE SUPPORT FINGER, YOU CAN GRIND PERFECT

FLANKS ON SPIRAL-FLUTED RADII CUTTING TOOLS. EVEN RADIAL

&PERIPHERAL CUTTING EDGES CAN BE GROUND IN A SINGLE OPERATION.

“UNIVERSAL WHEEL DRESSER”, DECKEL PART #2628000. FOR PROFILING OF GRINDING WHEELS, RADII& CYLINDRICAL, TAPERED

& PLANE SURFACES.

SUPPORT ARM ASSEMBLY (2576000) WITH TAILSTOCK CENTER & SUPPORT BLADE,

FOR UNIVERSAL INDEX HEAD ST-40 & MT4.

SWIVEL BRACKET ASSEMBLY (2626000) WITH TAILSTOCKS

DECKEL ST-40 COLLETS. (8) COLLETS. SIZES ARE:

1/4″, 5/16″, 3/8″, 1/2″, 5/8″, 3/4″, 7/8″ & ONE OTHER

ADAPTOR FOR ST-40 COLLETS TO ER-40 COLLETS:

ER-40 COLLETS SIZES:

(6) INCH SIZES …. 1/8″, 3/16″, 1/4″, 5/16″, 3/8″ & 1/2″

(9) METRIC SIZES …. 4-5, 8-7, 9-8, 10-9, 12-11, 13-12, 14-13, 17-16 & 21-20

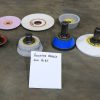

ASSORTMENT OF DECKEL CAMS

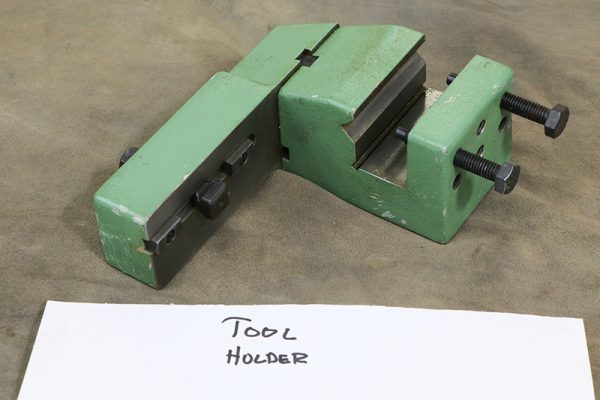

MACHINE VISE (2635000)

ADJUSTABLE IN THREE PLANES. WIDTH OF JAWS IS 3″. CLAMPING CAPACITY IS 3″.

ASSORTMENT OF GRINDING WHEELS & HUBS.

CABNET FOR ACCESSORY STORAGE. CABINET HAS INSERT PANELS, MADE FOR THE ACCESSORIES.

TOTAL POWER, 2KW, 220-480 VOLT, 50-60 HZ

MACHINE IS PRESENTLY WIRED FOR 3/60/220 VOLTS/8-14 AMPS

SPECIAL NOTE:

ISOG DECKEL S11 BROCHURE, DESCRIBES THE MACHINE NICELY: