Description

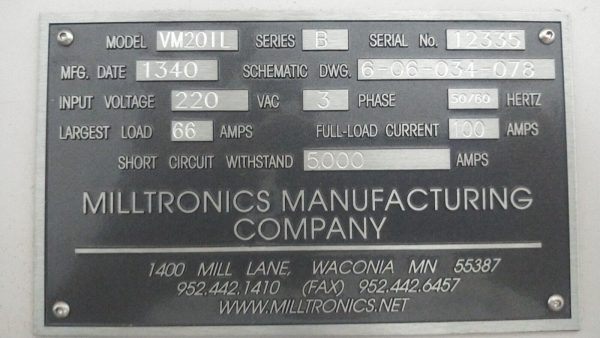

Milltronics VM20IL – Year 2013

cnc machining center 4 axis

travels: 40 X 20 inch

Tool Holder : CAT 40 dual contact

2 speed dual wound electronic gear 15K inline spindle.

dual washdown pumps.

chip auger.

Renishaw NC-4 non contact tool-setter and wireless probing.

24 pocket side arm tool changer.

1K IPM rapids.

rigid tapping.

peck tapping.

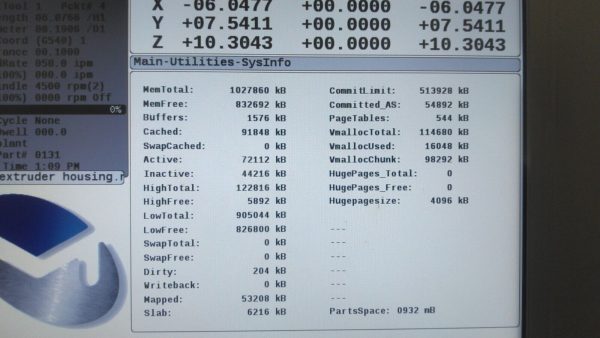

8200-B control.

USB and RJ-45.

LED lighting.

full 4th axis ready.

machine status 3 light tower.

Handwheel mode (allows you to handwheel through a program to make sure clearance really is clearance).

I bought this machine new in 2016 for my one-man shop.

I specialize in repairs and very small run production, my lot sizes are usually from 1-20 parts, this and all my machines are in a tool room setting. This machine has been well taken care of and is accurate enough to hold bearing fit tolerances consistently. programming is done via standard Fanuc G/M code, conversational, parametric, and logic. Concurrent programming (you can create, edit, send and receive programs while a program is running). 2000 block per second.

Wireframe and solid model graphics. User definable macros This machine is one of the last Milltronics mills that were manufactured here in the states before Hurco purchased the company, it truly is made in the USA.

I have posted a video of the machine demonstrating the spindle function,

As far as loading, I do not have a lift large enough to load the machine. I do have a local rigger that I use, Secrest rigging and machinery movers, that will be happy to quote anything from simple loading to portal to portal delivery and set-up. The only reason I am selling this machine is because I have a new one on the way. This one will be taken off power and stored in an insulated warehouse prior to sale that will be easier to load out of than my shop.