Description

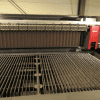

Mitsubishi ML3015eX – Year 2017

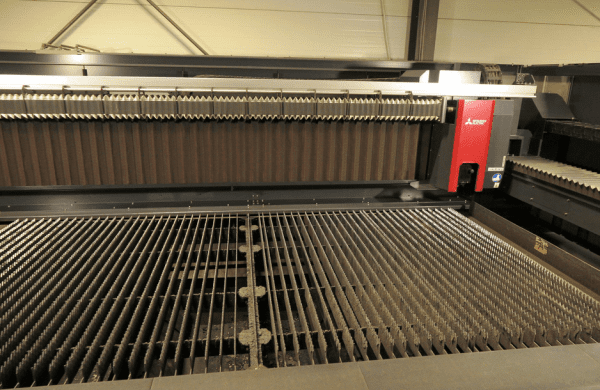

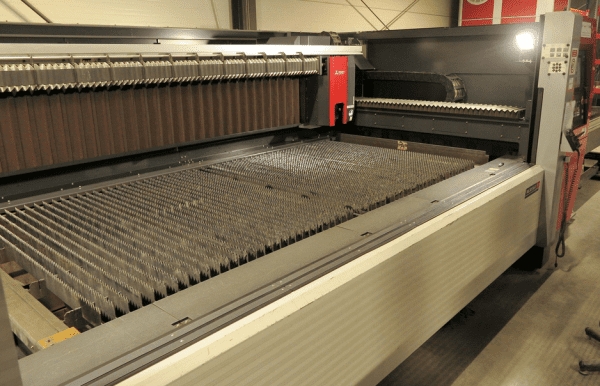

CNC laser cutting machine

| Metal length | 3050 mm |

| Power | 4500 W |

| Metal width | 1525 mm |

| Type | CO₂ |

| Option to cut tubes | no |

| Max thickness | 28 mm |

| CNC | yes |

| CNC type | MITSUBISHI M700 |

| Travel X | 3100 mm |

| Travel Y | 1565 mm |

| Travel Z | 1525 mm |

| Max weight of the workpiece | 930 kg |

| Mitsubishi ML3015eX | |

| Length x width x height | 10210.0 × 3130.0 × 2260.0 |

| Weight | 10700 kg |

Specifications of the MITSUBISHI ML3015eX PLUS laser

– laser power: 4.5 kW

– laser type: CO2

– feeds in the X/Y/Z axes: 3100/1565/150 mm

– maximum working area (L x W): 3100 x 1565 mm

– maximum sheet size (length x width): 3050 x 1525 mm

– maximum sheet weight: 930 kg

– maximum detail thickness (standard steel): 28 mm

– maximum detail thickness (stainless steel): 22 mm

– maximum detail thickness (aluminum): 18 mm

– maximum detail thickness (copper): 4 mm

– maximum detail thickness (brass): 4 mm

– maximum working speed: 50 m/min

– positioning accuracy: ± 0.05 mm

– positioning repeatability: ± 0.01 mm

– positioning speed with simultaneous operation of the X and Y axis drives: 100 m / min

– start-up time: 3 min

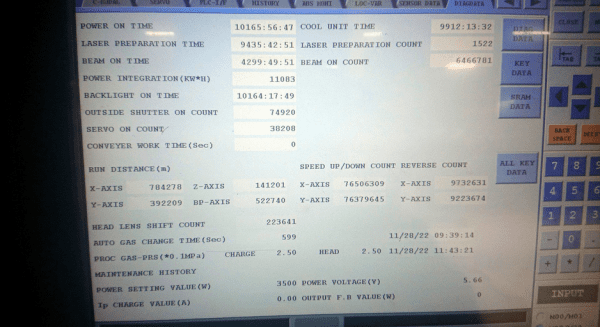

– beam working time: 4299 h

– laser gas consumption: 3 l/h

– compressed air consumption: 400 l/min

– power supply: 3x 200V; 50/60 Hz

– dimensions (length x width x height): 10210 x 3130 x 2260 mm

– weight of the laser source: 2200 kg

– weight of the ML3015eX PLUS machine: 10700 kg

Equipment for the MITSUBISHI ML3015eX PLUS laser cutter

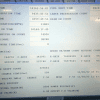

– CNC controller: MITSUBISHI M700

– laser source: MITSUBISHI ML45CF-R

– head: MITSUBISHI PH-XS

– replaceable table (2 pcs.)

– 15 touch screen

– 7.5″ and 10″ lenses

– autofocus

MITSUBISHI ML3015eX PLUS laser cutter was manufactured in 2017 by the renowned Japanese company Mitsubishi Electric. The machine uses the most modern technology available on the market to cut details made of ordinary steel, stainless steel, aluminium, copper and brass with a maximum weight of 930 kg.

The extremely efficient MITSUBISHI ML45CF-R resonator of the Cross-Flow type with transverse laser gas flow used in the laser is characterized by burr-free cutting of the highest quality and low surface roughness, without the need for time-consuming and expensive re-processing. The laser beam with a power of 4.5 kW is created by electric discharges in a special mixture of gases with a relatively slow flow and in the direction perpendicular to its axis.

The constant length of the beam generated by the laser source allows you to obtain the same high quality of cut throughout the working area of the machine. Beam power is monitored in real time to prevent power variations of more than ±1% needed to process highly reflective materials.

The MITSUBISHI ML3015EX(S2)-45CF-R laser cutter is equipped with a large working area of 3100 x 1565 mm, a modern CNC controller with a MITSUBISHI M700 touch screen and the intelligent ECO Mode function, reducing energy consumption in standby mode by up to 99%, gradually disconnecting individual components during unscheduled outages. The total weight of the laser cutter is 10,700 kg.